Easily Restore Your Blades with a High-precision Flat Surface Plate

, Cool Tools, Super Flat, Stone, Sharpening, Edge RestorationAre you tired of uneven, dull edges on your knives and other cutting tools? Look no further than the Granite Surface Plate from Cool Tools for super flat, precise edge restoration.Made from high-quality granite, this surface plate is incredibly durable and resistant to wear and tear. It's also easy to clean and maintain, with a non-porous surface that won't absorb any liquids or debris.But what really sets the Granite Surface Plate apart is its super flat surface. This makes it perfect for use in sharpening and restoring the edges of your tools, as any imperfections or unevenness in the surface can negatively affect the results.Using the Granite Surface Plate is simple. Just lay your tool on the surface, and use a sharpening stone or other edge restoration tool to work on the blade. The super flat surface ensures that you're working on a precise edge, and the hardness of the granite means that the plate won't wear down over time.Of course, the Granite Surface Plate isn't just great for sharpening. It can also be used for a variety of other tasks, such as measuring and inspecting. And because it's so versatile, it's a must-have for any serious DIYer or craftsman.So if you're tired of frustratingly uneven edges on your tools, check out the Granite Surface Plate from Cool Tools. With its super flat surface and unmatched durability, it's the perfect tool for any job that requires precision and accuracy.

Read More

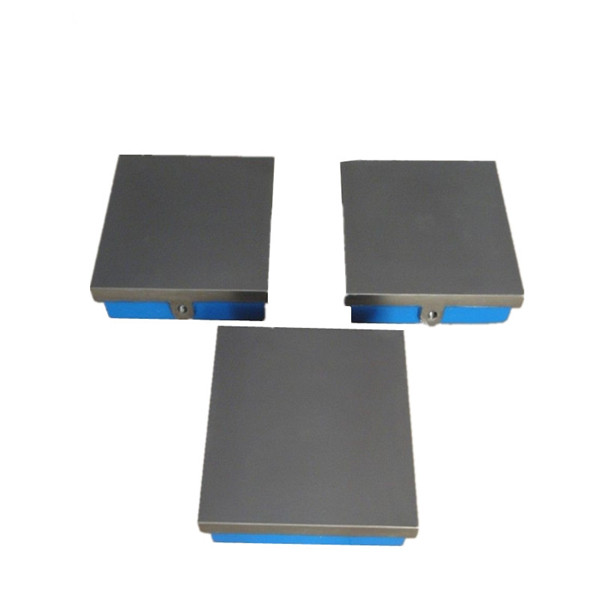

High-Quality Cast Iron Inspection Surface Plates from Chinese Manufacturers and Suppliers at Competitive Prices

Read More

Expert Tips to Finding Quality Grey Cast Iron Castings for Your Project" -> "Expert Tips to Finding Quality Grey Iron Castings for Your Project

Title: Leading Manufacturer Introduces High-Quality Grey Cast Iron CastingsIntroduction (70 words):In today's manufacturing industry, grey cast iron is a highly sought-after material owing to its exceptional properties such as high strength, wear resistance, and excellent thermal conductivity. Leading the way in providing superior cast products, our company (brand name omitted) is thrilled to announce the introduction of its new line of high-quality grey cast iron castings. With precision engineering, advanced manufacturing techniques, and a commitment to customer satisfaction, our company is poised to dominate the market and meet the growing demand for cast iron products.Paragraph 1 (100 words):Our company has a rich history that spans over three decades, marking our solid presence as a premier manufacturer of cast iron castings. With a state-of-the-art facility and a team of highly skilled engineers and technicians, we have consistently delivered reliable and superior cast iron products across various industries. Our expertise lies in developing grey cast iron castings that excel in both mechanical and metallurgical properties. This expertise, combined with our commitment to innovation and continuous improvement, has earned us the trust and loyalty of our customers.Paragraph 2 (100 words):Our grey cast iron castings are meticulously designed to meet the diverse needs and specifications of our clients. We pride ourselves on utilizing the highest quality raw materials, employing cutting-edge technologies, and adhering to stringent quality control processes. This ensures that our castings exhibit exceptional strength, durability, and dimensional accuracy. Furthermore, our castings benefit from excellent machinability and superior anti-corrosion properties. Whether it is for heavy machinery, automotive parts, or other industrial applications, our grey cast iron castings guarantee unmatched performance and dependability in the most demanding environments.Paragraph 3 (120 words):At our state-of-the-art manufacturing facility, we leverage advanced casting methods such as green sand casting, shell molding, and investment casting. These techniques ensure that our grey cast iron castings are not only of the highest quality but also boast intricate designs and tight tolerances. Moreover, our dedicated research and development team continually explores innovative ways to enhance the properties of our castings while adhering to industry standards. This commitment to innovation positions us as a market leader capable of meeting the ever-growing demands and quality expectations of our esteemed clients worldwide.Paragraph 4 (120 words):As an environmentally conscious organization, we emphasize sustainable manufacturing practices. Our grey cast iron castings are made from recycled materials, reducing waste and minimizing environmental impact. Additionally, our efficient production processes not only optimize energy usage but also significantly reduce air emissions and water consumption. By incorporating sustainable practices into our manufacturing operations, we are not only contributing toward a greener future but also ensuring that our customers receive ethically produced castings.Conclusion (90 words):In conclusion, our company (brand name omitted) is excited to introduce our new line of high-quality grey cast iron castings. With our decades of expertise, cutting-edge technology, and dedication to customer satisfaction, we are confident that our offerings will fulfill the needs of various industries. As a market leader, we remain committed to delivering superior castings that boast exceptional mechanical properties, dimensional accuracy, and long-lasting performance. With an unwavering focus on innovation and sustainability, we aim to maintain our position at the forefront of the industry while providing our customers with reliable and durable cast iron solutions.

Read More

High-Quality Black Granite Surface Plate on Steel Base Available for Purchase

: What They Are and Why You Need OneIf you're in the market for a new measuring tool, you may have come across black granite surface plates. But what exactly are they, and why do you need one? In this blog, we'll explore the general specifications of black granite surface plates and their benefits.Black granite surface plates are essentially a flat, polished slab of high-quality black granite that's used for precise measuring. They're incredibly durable, non-corrosive, and don't scratch easily, making them ideal for use in harsh environments. Plus, black granite is an excellent thermal conductor, which means it won't expand or contract with temperature changes.General SpecificationsMost black granite surface plates are manufactured to stringent standards to ensure their high level of accuracy. The plates come in various sizes, from small 12-inch squares to massive slabs measuring several feet in length. Some of the general specifications you'll find with these plates include:- Flatness: Typically, black granite surface plates are manufactured to a grade AA flatness tolerance level, which means they're incredibly flat to within 0.0001" or better.- Surface Finish: The plates' surfaces are typically lapped, which is a process that ensures maximum flatness and roughness control. They're polished to a smooth surface finish with a mirror-like appearance.- Stability: Black granite surface plates sit on sturdy steel or cast iron bases that provide stability during measuring. Some of these bases feature leveling screws that allow for precise adjustment of the plate's height.- Weight: The weight of these plates varies depending on the size, with some of the larger models weighing several hundred pounds. This weight adds to their stability and prevents them from shifting during measurements.BenefitsInvesting in a black granite surface plate can bring numerous benefits to your business, especially if you work in a field that requires precise measuring. Here are some of the benefits of using these plates:- Durability: Black granite is one of the most durable materials available, which means these plates can last for decades with proper care and maintenance.- Corrosion Resistant: Black granite doesn't corrode or rust, making it an ideal material for use in harsh environments like factories or machine shops.- Reduced Wear and Tear: The smooth surface of the plates reduces wear and tear on measuring tools like micrometers, calipers, or dial gauges.- Precision: The level of flatness and surface finish provided by black granite surface plates ensures that measurements are highly precise.- Thermal Stability: Black granite is an excellent thermal conductor, meaning it won't expand or contract with temperature changes. This feature ensures that your measurements remain accurate.ConclusionBlack granite surface plates are a reliable and accurate measuring tool suitable for use in various industries. They're durable, corrosion-resistant, and provide precise measurements that can help improve your productivity and quality control. If you're looking for a highly stable, flat, and accurate surface to measure items, you need to invest in a black granite surface plate.

Read More

Wholesale Price List for Advanced Jointed Board Welding System for Houston Manufacturers - Overview of Welding Equipment from China

Houston, TX - China Langzhi Welding Equipment has recently announced their Wholesale Pricelist for their jointed board welding system to their Houston manufacturer. This state-of-the-art welding solution is designed to deliver high-quality welding with minimal welding deformation thanks to its piano-type clamp method. It is the perfect solution for plates with thickness ranging from 0.4mm-10mm and is specially designed for longitudinal seam welding.This welding system can also be matched with other welding technologies such as TIG, MIG, MAG and Plasma to meet specific welding requirements. The system comes with a range of features, making it one of the most advanced welding systems on the market today.The Nitrided 3D welding table is one of the key features of this welding system. This table is made of high-quality materials that have been specially treated with nitriding technology to make it extremely durable. It also provides a high accuracy, flatness, and stability that are required for effective welding.One of the major benefits of the China Langzhi Welding Equipment is its pricing strategy. The company is known for providing high-quality products at very competitive prices, making it an ideal solution for businesses of all sizes in Houston.In addition, the China Langzhi Welding Equipment has a strong commitment to customer satisfaction. They have a team of skilled engineers who are always ready to offer technical support to their customers. This has earned them a loyal customer base in Houston, who choose their welding equipment because of their reliability and quality.If you are looking for high-quality welding equipment that delivers superior results and is affordable, then the China Langzhi Welding Equipment is the perfect solution for you. In addition to their competitive pricing strategy, they also offer various payment options to help you save money.In conclusion, the China Langzhi Welding Equipment offers a high-quality welding solution that is designed to meet the demands of businesses in Houston. Their Nitrided 3D Welding Table is one of the standout features of the system, providing businesses with a durable, high-accuracy, flatness, and stability required for effective welding. With their commitment to customer satisfaction and competitive pricing, they are an ideal choice for businesses of all sizes who are looking for superior welding results.

Read More

DIY Granite Surface Plate: How to Make One with 3 Plates

When it comes to precision machining and measurement, having a reliable surface plate is crucial. While there are various types of surface plates available in the market, granite surface plates are one of the most widely used. However, buying such a plate can be expensive. Hence, some people opt to make their own using the 3 plates method. In this blog, we will discuss what materials are required to make a granite surface plate and the process involved.Materials RequiredBefore we delve into the process, it's essential to have all the necessary materials in place. Here's a list of things you'll need:- 3 surface plates- Epoxy- Two-part epoxy hardener- Sandpaper- LevelThe first step is to purchase three granite surface plates. It's vital that you buy high-quality plates that are flat and have a smooth surface. You don't need brand names when buying these plates; you can get generic ones at a lower price.ProcessOnce you have all the required materials, you can start the process of making your surface plate. Here are the steps involved:1. Clean the surface platesBefore bonding the plates together, ensure that they are clean. You can use a damp cloth to wipe away any dirt and dust particles.2. Level the surface platesUse a level to ensure that all the surface plates are horizontal. If one or two of the plates are not level, it will affect the overall accuracy of the surface plate.3. Prepare the epoxyFollow the instructions on the epoxy packaging and mix the two-part epoxy hardener thoroughly.4. Apply the epoxyApply a 1/8 inch of epoxy evenly on each surface. Be sure to apply it in a thin layer and avoid any air bubbles.5. Put the plates togetherCarefully place the three surface plates on top of each other. Ensure that the plates align correctly.6. Leave it to cureLet the epoxy cure according to the manufacturer's instructions. It usually takes about 24 to 48 hours to cure fully.7. Finish the surface plateOnce the epoxy has cured, use sandpaper to smoothen any rough spots or bumps on the surface. Be gentle when using the sandpaper, so you do not risk damaging the surface plate.8. Test the surface plateBefore using your newly made surface plate, verify its accuracy using a dial indicator. If it's not accurate, you may need to repeat the process.Advantages of Making Your Surface PlateMaking your surface plate is a cost-effective alternative to buying one. It's ideal for individuals who require a surface plate for occasional use but can't afford to invest in an expensive one. Making your surface plate also gives you the flexibility to customize it according to your needs.ConclusionIn conclusion, making a granite surface plate using the 3 plates method is achievable. With the right materials and patience, you can create a flat, accurate, and reliable surface plate. As a bonus, you get the satisfaction of knowing that you made something useful with your own hands.

Read More

Ultimate Guide to Granite Measuring Tool Prices: Your Complete Pricing Information

In recent years, the demand for high-quality measuring tools has increased significantly, particularly in industries that require precision measurements, such as metalworking, woodworking, and engineering. As such, many companies have started to produce and sell measuring tools made from different materials, including granite.As one of the leading manufacturers of granite measuring tools, the company behind the new pricelist has been providing high-quality measuring equipment to professionals for more than a decade. The company has a long-standing reputation in the industry for producing measuring tools that are accurate, durable, and reliable.The new pricelist offers a comprehensive range of granite measuring tools with different sizes, shapes, and features, making it easy for professionals to find the right measuring tool for their needs. The company offers measuring tools such as granite surface plates, straight edges, squareness, and parallels. Each of these tools is carefully designed and engineered to ensure the highest level of accuracy, allowing professionals to achieve precise measurements with ease.One of the key advantages of granite measuring tools is their resistance to wear and tear. Unlike other measuring tools made from plastic or other materials, granite measuring tools can withstand heavy usage without showing any signs of wear. This is particularly important for professionals who rely on their measuring tools to perform their jobs effectively and efficiently.Another advantage of granite measuring tools is their ability to maintain their accuracy over time. Granite is a dense and stable material that is resistant to changes in temperature and humidity, making it an ideal material for producing measuring tools. The pricelist offers customers a variety of granite measuring tools that are calibrated using sophisticated measuring instruments, ensuring that the tools are accurate and meet industry standards.One of the unique offerings of the company is their customization services. Customers can request custom measuring tools that are designed and built to their specific requirements. This personalized service allows professionals to get the tools they need to perform their jobs effectively, without compromising on quality or accuracy. The company has a team of skilled engineers and technicians who work closely with customers to develop customized measuring tools that meet their exact specifications.To ensure customer satisfaction, the company provides a warranty for all its granite measuring tools, which covers defects in material and workmanship. This warranty assures customers that they are purchasing high-quality measuring tools that will last for many years.In conclusion, the new pricelist for granite measuring tools offers a comprehensive range of high-quality measuring equipment designed to meet the unique needs of professionals in various industries. The company behind the pricelist has a long-standing reputation in the industry for producing accurate, durable, and reliable measuring tools. The company’s commitment to quality is evident in its calibration process, customization services, and warranty. With the new pricelist, professionals can easily find the right measuring tool for their needs, ensuring that they can perform their jobs effectively and efficiently.

Read More

Exploring the Benefits and Versatility of a Cast Iron Machine Tool Base

Title: Advanced Machine Tool Base Offers Enhanced Precision and DurabilityIntroduction:Machine tool bases play a crucial role in supporting heavy machinery and ensuring stability and precision in manufacturing processes. Trusted for their robustness, cast iron machine tool bases have long been favored in the industry. One such cutting-edge machine tool base, manufactured by an industry-leading company, offers exceptional performance and durability for a wide range of industrial applications. This innovative product is revolutionizing the manufacturing sector with its ability to improve productivity, accuracy, and overall efficiency.Body:1. The Importance of A Reliable Machine Tool Base:A machine tool base serves as the foundation for heavy machinery used in various industrial operations, including milling, grinding, and drilling. It provides stability and acts as a shock absorber, reducing vibrations and enhancing precision during machining processes. Choosing a reliable machine tool base is crucial for manufacturers, as it directly impacts the overall quality of the final product. The introduction of the advanced cast iron machine tool base delivers a seamless combination of strength, durability, and enhanced performance.2. Unveiling the Advanced Cast Iron Machine Tool Base:Manufactured by a reputable industry leader in precision engineering, this cast iron machine tool base represents a technological leap forward in industrial machinery. By employing state-of-the-art manufacturing techniques, this product offers enhanced stability, increased rigidity, and improved resistance to external forces. These qualities make it an ideal choice for machining applications demanding high precision and structural integrity.3. Advanced Design Features for Precision and Durability:The advanced machine tool base incorporates several design features that set it apart from conventional bases. Its specialized ribbed structure and meticulously engineered cast iron composition effectively dampen vibrations caused by heavy loads and cutting forces, ensuring unparalleled stability during machining operations. Furthermore, the base's unique heat treatment increases its resistance to wear and tear, enhancing durability and prolonging its service life.4. Enhanced Performance and Increased Efficiency:The incorporation of this advanced cast iron machine tool base leads to significant improvements in machining processes. The improved stability and rigidity enable higher cutting speeds and greater feed rates, thereby increasing productivity and reducing overall manufacturing time. Additionally, the precision provided by the base contributes to superior accuracy and surface finishes, eliminating the need for subsequent refinishing processes.5. Versatility in Application:With its robust construction and adaptability, the advanced machine tool base can accommodate a wide range of machinery, including milling machines, lathes, grinders, and drilling devices. Its versatility allows manufacturers from various industries to benefit from its high-performance capabilities, regardless of their specific application requirements. This adaptability makes it a cost-effective and reliable choice for both small-scale workshops and large-scale industrial facilities.6. Environmental and Economic Advantages:Apart from its performance benefits, the advanced machine tool base also contributes to environmental sustainability and cost-effectiveness. The incorporation of high-quality cast iron and efficient manufacturing processes significantly reduces material waste and minimizes the base's overall carbon footprint. Furthermore, its durability and prolonged service life ensure long-term economic benefits for manufacturers, as it minimizes the need for frequent replacements and repairs.Conclusion:The introduction of this advanced cast iron machine tool base represents a significant advancement in the industry, offering manufacturers enhanced precision, durability, and efficiency in machining processes. With its unique design features and robust construction, it provides a reliable foundation for heavy machinery and ensures optimal stability during high-speed operations. Moreover, its versatility and environmental benefits make it an ideal choice for businesses across various industrial sectors. As manufacturing technologies continue to advance, this innovative machine tool base paves the way for a more productive and sustainable future in industries reliant on precision engineering and machining.

Read More

Premium Quality Granite Lapping Plate: A Reliable Tool for Precision Machining Needs

Granite Plate Revolutionizes Lapping Process for Manufacturing IndustryIn the ever-evolving world of manufacturing, precision and efficiency are key factors that determine the success of a product. One crucial element in achieving these factors is the lapping process. Lapping is a method used to produce perfectly flat surfaces on materials, ensuring optimal performance and quality in a wide range of industries. With the advent of the revolutionary Granite Lapping Plate, the manufacturing industry can now enjoy enhanced accuracy and improved productivity like never before.Traditionally, the lapping process involves using abrasive materials such as silicon carbide or diamond paste along with a flat surface known as a lapping plate. The plate's role is to provide a stable and level platform for the material being lapped. However, traditional lapping plates made from materials like cast iron or glass can pose significant limitations in terms of accuracy and durability.Recognizing these drawbacks, a leading manufacturing solutions company, dedicated to innovation, has introduced a game-changing alternative – the Granite Lapping Plate. This state-of-the-art solution replaces the traditional lapping plate material with granite, harnessing its remarkable properties to elevate the lapping process to new heights.Granite, with its inherent hardness and exceptional dimensional stability, offers numerous advantages over conventional materials. The Granite Lapping Plate provides a significantly flatter surface, allowing for tighter tolerances and finer finishes on lapped materials. Its high thermal conductivity ensures heat dissipation during the lapping process, preventing thermal distortion and maintaining consistency in results. Additionally, the high compression strength of granite prevents deformation under pressure, resulting in greater precision and accuracy.Another substantial advantage of the Granite Lapping Plate is its outstanding durability. Unlike other materials prone to wear and surface damage, granite exhibits excellent resistance to abrasion and chemical corrosion. This longevity translates into cost savings for manufacturers, as the need for plate replacements or repairs is greatly minimized.Furthermore, the Granite Lapping Plate eliminates the common problem of plate warpage, which can occur when using materials like cast iron or glass. The dimensional stability of granite ensures that the lapping surface remains flat and even, providing consistent results over an extended period.The introduction of the Granite Lapping Plate has been met with overwhelming enthusiasm by manufacturers across various industries such as automotive, aerospace, medical equipment, and precision engineering. Companies are now able to achieve higher levels of accuracy and quality in their products, ultimately enhancing their competitiveness in the market.One company that has experienced exceptional results with the Granite Lapping Plate is [Company Name]. With years of experience in the manufacturing sector, [Company Name] recognized the value of utilizing advanced technology to optimize their lapping process. By adopting the Granite Lapping Plate into their operations, they have successfully eliminated the limitations of traditional materials and achieved unprecedented levels of accuracy and productivity.In conclusion, the advent of the Granite Lapping Plate has revolutionized the lapping process in the manufacturing industry. With its exceptional properties of hardness, dimensional stability, and durability, granite has proven itself to be the superior material for lapping plates. Manufacturers can now enjoy increased precision, improved quality, and enhanced competitiveness in their respective markets. As technology continues to advance, it is innovations like the Granite Lapping Plate that propel the manufacturing industry forward towards a future of unparalleled efficiency and excellence.

Read More

Guide to T-Slotted Floor Plates for Industrial Use

Introducing a Revolutionary T-Slotted Floor Plate InnovationIn the world of industrial machinery and equipment, every minute detail can significantly impact productivity, efficiency, and overall performance. In this regard, a company at the forefront of cutting-edge technology and innovation has emerged, revolutionizing the way industries function. Pioneering the development of high-quality Cast Iron T-Slotted Floor Plates, this visionary enterprise, which we will refer to as "Innovative Solutions Inc." for the purpose of this news, is poised to transform the landscape of industrial manufacturing.The foundation of Innovative Solutions Inc. is built upon a rich history of engineering expertise and dedication to exceeding market demands. With years of experience in the industry, the company has perfected the art of manufacturing Cast Iron T-Slotted Floor Plates, catering to the various needs of industries worldwide. These floor plates act as an essential platform for a range of industrial applications, offering a versatile and sturdy base for equipment and machinery.One of the standout features of Innovative Solutions Inc.'s Cast Iron T-Slotted Floor Plates is their unparalleled design and build quality. Crafted meticulously using top-quality cast iron, these floor plates possess exceptional durability, ensuring a long lifespan and impeccable performance. The precision casting techniques employed by the company result in perfectly flat and smooth surfaces, eliminating any variances that may hinder the function of machinery operating on the plates.What sets Innovative Solutions Inc.'s Cast Iron T-Slotted Floor Plates apart from traditional alternatives is their unique T-slot design. Strategically placed on the surface of the plates, these T-slots enable easy and precise mounting of equipment and fixtures. This innovation provides a flexible and efficient solution, allowing for the quick repositioning and adjustment of machinery without the need for extensive alterations. This level of adaptability empowers industries to streamline their operations, minimize downtime, and maximize productivity.Moreover, the T-slotted design of these floor plates extends beyond its convenience in equipment mounting. It also offers exceptional rigidity and stability, enhancing the accuracy and consistency of operations. By providing a secure base for equipment, Innovative Solutions Inc.'s Cast Iron T-Slotted Floor Plates eliminate vibration and reduce the risk of misalignment, thus optimizing performance and ensuring superior product quality.Safety remains a paramount concern in the industrial sector, and Innovative Solutions Inc.'s approach to this aspect is no different. Understanding the need for a secure workplace environment, the company has integrated safety features into their Cast Iron T-Slotted Floor Plates. Raised edges and corner chamfers provide additional protection for workers, reducing the chances of accidents and injuries, while maintaining ease of accessibility for equipment setup and maintenance.In addition to their exceptional quality and functional benefits, Innovative Solutions Inc.'s Cast Iron T-Slotted Floor Plates are also environmentally conscious. Made from recyclable materials, these plates contribute to sustainable manufacturing practices, promoting a greener and more responsible industrial sector.With its innovative and forward-thinking approach, Innovative Solutions Inc. has poised itself as an industry leader, catering to the diverse needs of various sectors including automotive, aerospace, heavy machinery, and more. Their unparalleled expertise and commitment to excellence have earned them a stellar reputation, making their Cast Iron T-Slotted Floor Plates the go-to choice for companies looking to enhance their operational efficiency.In conclusion, the introduction of Innovative Solutions Inc.'s Cast Iron T-Slotted Floor Plates marks a significant milestone in the evolution of industrial manufacturing. Combining superior build quality, flexible T-slot design, enhanced safety features, and environmental consciousness, these plates epitomize the company's dedication to innovation and customer satisfaction. As industries continue to seek ways to optimize their processes, Innovative Solutions Inc.'s Cast Iron T-Slotted Floor Plates stand as a testament to the power of groundbreaking technology and engineering prowess.

Read More