High-Quality Granite Bases for Machine Components

By:Admin

Machine Components Granite Bases offers a wide range of granite bases that are suitable for use in a variety of applications, including machining, precision measurement, and industrial machinery. The company's products are known for their superior quality and durability, making them the preferred choice for many businesses in need of reliable and long-lasting machine components.

One of the main factors that sets Machine Components Granite Bases apart from its competitors is its focus on using only the finest quality materials in the production of its granite bases. The company sources its granite from reputable quarries, ensuring that each base is made from premium-grade stone that is capable of withstanding heavy loads and harsh working conditions.

In addition to its commitment to quality, Machine Components Granite Bases also places a strong emphasis on innovation and continuous improvement. The company's team of experienced engineers and designers are constantly working to develop new and improved products that meet the evolving needs of its customers. This dedication to innovation has helped Machine Components Granite Bases stay ahead of the curve and maintain its position as a leading provider of machine components.

Furthermore, Machine Components Granite Bases understands the importance of providing exceptional customer service. The company's knowledgeable and friendly staff are always ready to assist customers with their inquiries and provide expert guidance on choosing the right granite bases for their specific needs. Whether it's a custom order or a standard product, Machine Components Granite Bases prides itself on delivering a seamless and reliable customer experience.

With its unwavering commitment to excellence, it comes as no surprise that Machine Components Granite Bases has garnered a loyal and satisfied customer base. Businesses across various industries have come to rely on the company's products for their machine component needs, trusting in the durability and performance of its granite bases.

Looking ahead, Machine Components Granite Bases is poised to continue its success and further establish itself as a trusted name in the industry. The company's dedication to quality, innovation, and customer satisfaction will undoubtedly drive its future growth and solidify its position as a leader in the market.

In conclusion, Machine Components Granite Bases has proven itself to be a company of exceptional quality and reliability, offering top-notch granite bases that meet the needs of various industries. With a focus on using premium materials, continuous innovation, and outstanding customer service, the company has set itself apart as a leader in the market. As the demand for high-quality machine components continues to grow, Machine Components Granite Bases is well-positioned to meet and exceed the expectations of its customers, solidifying its place as a top provider of granite bases for years to come.

Company News & Blog

Revive Your Blades with a Super Flat Granite Surface Plate

Granite Surface Plate Helps Restore Blades to PerfectionIf you're a woodworker or metal worker, you know how important it is to have a sharp blade. A dull blade not only makes it difficult to get a clean cut, but it can also be dangerous. That's why many professionals turn to a granite surface plate to restore their blades.The granite surface plate, also known as a surface table or precision granite plate, is a flat stone slab made of granite. This natural stone is prized for its hardness, durability, and resistance to wear and tear. Granite surface plates are often used in manufacturing, machining, and metrology to provide a flat surface for measuring and testing. But they are also becoming more popular among hobbyists and DIY enthusiasts for sharpening blades.One company that offers granite surface plates for blade restoration is Cool Tools. Based in Santa Fe, New Mexico, Cool Tools has been supplying craftsmen, metalworkers, and jewelry makers with high-quality tools and equipment since 1995. They offer a range of granite surface plates in different sizes and thicknesses, as well as other accessories to help with blade restoration.To use a granite surface plate for blade restoration, you'll need a piece of sandpaper or a sharpening stone and some honing oil. Simply lay the surface plate flat on a table or workbench, then place your blade on the plate at the desired angle. Start with a coarse grit sandpaper or stone to remove any nicks or chips in the blade, then move on to a finer grit to polish the edge. Apply honing oil to the surface plate to lubricate the blade and prevent it from overheating.One of the benefits of using a granite surface plate for blade restoration is its flatness. The surface plate is guaranteed to be flat within a certain tolerance, usually measured in microns. This means that the surface is perfectly level and straight, allowing you to sharpen your blade evenly and accurately. Some surface plates even come with calibration certificates that verify their precision.Another advantage of using a granite surface plate for blade restoration is its durability. Unlike other materials such as glass or metal, granite is less likely to warp or bend over time. This means that your surface plate will last for years, even with heavy use. Granite is also less likely to scratch or chip, which can damage your blade or cause it to become dull more quickly.In addition, granite surface plates are easy to clean and maintain. Simply wipe them down with a damp cloth after use to remove any debris or oil. You can also use a mild detergent if necessary. Avoid using harsh chemicals or abrasive cleaners, as these can scratch the surface and dull your blade.If you're interested in using a granite surface plate for blade restoration, consider purchasing one from Cool Tools. They offer a range of sizes and thicknesses to suit your needs, as well as other accessories such as honing oil and rubber feet to keep your surface plate stable during use. Cool Tools also offers excellent customer service and fast shipping, so you can start restoring your blades to perfection in no time.

Durable and High-Quality Machine Spare Parts for Granite Cutting Equipment

Granite Machine Spare Parts, a leading provider of high-quality spare parts for the granite industry, has announced the launch of their new line of innovative and durable spare parts for granite processing. With a commitment to excellence and customer satisfaction, the company has become a trusted name in the industry, offering a wide range of products to meet the needs of their clients.Established in [year], Granite Machine Spare Parts has quickly risen to prominence in the industry due to their dedication to quality and innovation. The company specializes in providing spare parts for a variety of machines used in granite processing, including cutting, polishing, and shaping machines. With a team of highly skilled engineers and technicians, Granite Machine Spare Parts is able to develop and manufacture high-performance spare parts that are designed to withstand the rigorous demands of the granite processing industry.One of the key factors that sets Granite Machine Spare Parts apart from their competitors is their unwavering commitment to quality. The company uses only the finest materials and manufacturing processes to ensure that their spare parts are of the highest standard. This dedication to quality has earned them a reputation for reliability and durability, making them the go-to choice for businesses in the granite industry.In addition to their commitment to quality, Granite Machine Spare Parts also places a strong emphasis on innovation. The company is constantly investing in research and development to create new and improved spare parts that offer enhanced performance and efficiency. Their team of engineers and technicians work tirelessly to stay ahead of the curve, ensuring that their clients have access to the latest advancements in technology.Granite Machine Spare Parts is also known for their exceptional customer service. The company takes great pride in building strong, long-lasting relationships with their clients, and they are dedicated to providing the highest level of support and assistance. Their team of knowledgeable and friendly staff is always on hand to answer any questions and provide expert guidance, helping their clients to find the perfect spare parts for their specific needs.With the launch of their new line of spare parts for granite processing, Granite Machine Spare Parts is poised to further strengthen their position as a leader in the industry. The new range features a variety of innovative products that have been specifically designed to improve efficiency and productivity in granite processing operations. From cutting blades to polishing pads, the new line offers a comprehensive selection of spare parts to meet the diverse needs of their clients.As part of their commitment to excellence, Granite Machine Spare Parts is also offering a warranty on all of their new products, providing their clients with added peace of mind. The company stands behind the quality and performance of their spare parts, and they are confident that their clients will be satisfied with their investment.For businesses in the granite industry looking for reliable, high-performance spare parts, Granite Machine Spare Parts is the clear choice. With their commitment to quality, innovation, and customer service, the company has established themselves as a trusted partner for businesses seeking to optimize their operations. The launch of their new line of spare parts is a testament to their ongoing dedication to providing the best products and support for their clients.

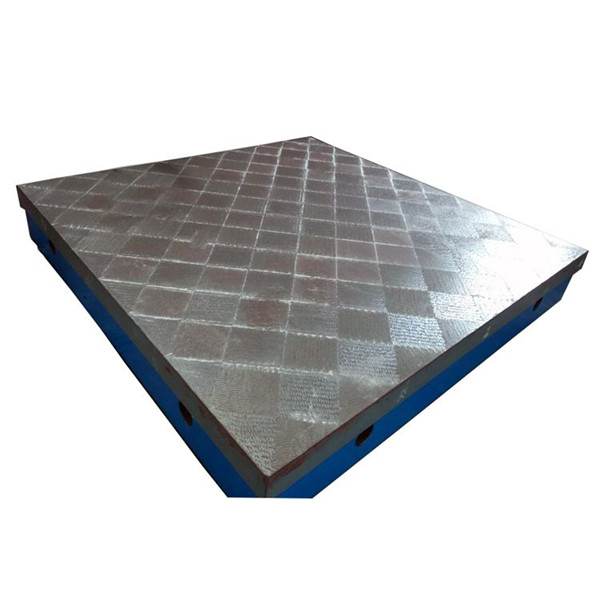

High-Quality Cast Iron Surface Inspection Plates for Industrial Use

Cast Iron Surface Inspection Plate, a renowned product in the industrial manufacturing sector, has become a go-to solution for ensuring accurate and precise measurements. This exceptional product is manufactured and distributed by a leading company that has been serving the industry for several decades.The company, with a rich history and a strong reputation, has consistently delivered high-quality products and has been a trusted partner for companies across the globe. Their commitment to excellence and innovation has enabled them to carve a niche for themselves in the competitive market.The Cast Iron Surface Inspection Plate is a testament to the company's dedication to providing top-notch solutions for the manufacturing industry. It is designed to meet the most demanding requirements of precision measurement and inspection processes. The plate offers a robust and stable surface for conducting accurate measurements, making it an indispensable tool for manufacturers in various sectors such as automotive, aerospace, and machinery.One of the key features of the Cast Iron Surface Inspection Plate is its exceptional flatness and stability. This ensures that the measurements taken on the surface are reliable and consistent, allowing manufacturers to maintain the highest quality standards in their production processes. Additionally, the plate's durability and resistance to wear and tear make it a cost-effective investment for companies looking to enhance their measurement capabilities.Moreover, the Cast Iron Surface Inspection Plate is available in a variety of sizes and configurations, catering to the diverse needs of different industries. Whether it is for precision machining, assembly, or quality control, the plate can be customized to meet specific requirements, further demonstrating the company's commitment to customer satisfaction.In addition to its superior quality, the company also offers exceptional customer service and support. Their team of experts is dedicated to understanding the unique needs of each client and providing personalized solutions that address specific challenges. This commitment to customer-centricity has earned them a loyal clientele who rely on their expertise and reliability.Furthermore, the company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every Cast Iron Surface Inspection Plate that leaves their premises meets the highest standards of craftsmanship. This attention to detail and quality assurance has helped them build a strong reputation as a trusted supplier of industrial products.With a strong global presence and a network of distributors, the company has successfully catered to the needs of clients from around the world. Their commitment to timely delivery and efficient logistics has made them a preferred partner for companies seeking reliable and durable solutions for their manufacturing processes.In conclusion, the Cast Iron Surface Inspection Plate, manufactured and distributed by the esteemed company, stands out as a premier product in the industrial manufacturing sector. Its exceptional quality, precision, and reliability make it an indispensable tool for companies looking to enhance their measurement and inspection capabilities. With a legacy of excellence and a dedication to customer satisfaction, the company continues to set the benchmark for delivering innovative and top-of-the-line industrial solutions.

Find PowerPoint Presentations, PDF Documents, Templates and Diagrams Easily on authorSTREAM - Page 1

Wedge Presentations: Making Your Presentations Stand OutWhen it comes to making a presentation, it’s not only about the content that you put on your slides. In fact, the way you present your ideas with your visual aids is just as important. This is where Wedge Presentations comes in. With their plethora of PowerPoint and Keynote presentations, PDF documents, PowerPoint templates, and diagrams, you can rest assured that your presentation will stand out.One of the key advantages of Wedge Presentations is the variety of materials they offer. You can easily find pre-made presentations on topics ranging from business to education, as well as presentations tailored to specific industries or situations. This makes it easy for you to find the content that matches your needs, without having to start from scratch.When it comes to creating a compelling presentation, the use of visual aids is critical. Wedge Presentations offers an array of diagrams and templates that can be easily customized to match your brand and style. This is particularly useful for businesses and organizations that want to ensure that all their presentations reflect their branding.If you’re looking to create a presentation that is both informative and visually appealing, Wedge Presentations also offers a variety of animation and transition effects. These effects can help keep your audience engaged and make your presentation more dynamic.But Wedge Presentations doesn’t just offer pre-made templates and animations. They also offer a unique feature called Long Steel Wedge. This is a specialized wedge that can be used to split wood, loosen tight bolts, and perform other tasks where a strong, durable wedge is needed.The Long Steel Wedge is an innovation that sets Wedge Presentations apart from other presentation providers. By using this wedge as a metaphor for the strength and durability of their presentations, Wedge Presentations emphasizes the quality and impact of their products.In conclusion, Wedge Presentations is an excellent resource for anyone looking to create a dynamic and impactful presentation. With their vast selection of pre-made presentations, templates, and diagrams, as well as unique features like the Long Steel Wedge, they offer an unmatched level of customization and creativity. So whether you’re a business professional, educator, or student, Wedge Presentations has everything you need to make your presentations stand out.

Durable Granite Surface Plate for Small-scale Projects

[Company Name], a leading manufacturer of precision measuring tools, has recently launched a new Small Granite Surface Plate designed to meet the diverse needs of its customers in the manufacturing and metrology industry. This new addition to their product line is set to provide precise measurements and a stable surface for a wide range of applications.The Small Granite Surface Plate is a vital tool in the manufacturing and engineering industry for the inspection and calibration of precision instruments. It provides a flat and stable surface for the accurate measurement of parts and components. Made from high-quality granite, the surface plate is resistant to wear and tear, ensuring longevity and reliability in its performance.With a compact design and a range of size options, the Small Granite Surface Plate offered by [Company Name] is suitable for various industrial and laboratory settings. The company has utilized advanced technology and manufacturing processes to ensure that the surface plate meets the highest standards of accuracy and durability. This new addition to their product line reflects their commitment to providing innovative solutions to their customers' needs.[Company Name] has built a strong reputation in the industry for its precision measuring tools and equipment. The company's focus on quality, reliability, and accuracy has made it a trusted provider for businesses across the globe. With a team of experienced engineers and experts, [Company Name] has been able to deliver cutting-edge products that meet the evolving needs of the industry.In addition to the Small Granite Surface Plate, [Company Name] offers a comprehensive range of precision measurement tools, including height gauges, micrometers, calipers, and vision measuring systems. The company also provides custom solutions and services to meet specific customer requirements, demonstrating their dedication to customer satisfaction.The introduction of the Small Granite Surface Plate further solidifies [Company Name]'s position as a leader in the precision measuring industry. The company's continuous investment in research and development, coupled with their commitment to quality and innovation, has allowed them to stay ahead of the competition and meet the ever-changing demands of the market."We are thrilled to introduce our new Small Granite Surface Plate to the market," said [Spokesperson Name], the CEO of [Company Name]. "This is a testament to our ongoing efforts to provide our customers with the best-in-class precision measurement tools. We believe that this new addition will not only enhance our product offering but also provide our customers with the reliability and accuracy they need for their measurement applications."The Small Granite Surface Plate offered by [Company Name] is now available for purchase through their global network of distributors and partners. The company remains committed to supporting their customers with top-notch products and services, further reinforcing their position as a trusted provider in the industry.As technology and innovation continue to drive the manufacturing and metrology industry, [Company Name] remains dedicated to staying at the forefront of the market, providing cutting-edge solutions that meet the evolving needs of their customers. The introduction of the Small Granite Surface Plate is a testament to the company's commitment to excellence and their relentless pursuit of delivering the best precision measurement tools to the industry.

Durable Welding Table Tops with Customizable Holes for Precision Work

The welding industry is constantly evolving, and welding tables play a crucial role in ensuring precision and efficiency in welding operations. A welding table with a flat, sturdy top and strategically placed holes can make a significant difference in the quality of work produced. Recently, a notable player in the welding equipment industry, {remove brand name}, has released a new welding table top with holes that promises to revolutionize the way welding is done.{Remove brand name} is a well-established company known for its high-quality welding products and innovative solutions. With a commitment to providing superior equipment to the welding industry, the company has gained a strong reputation for reliability and performance. Their new welding table top with holes is the latest addition to their extensive range of welding equipment, and it is set to make a significant impact on the industry.The welding table top with holes is designed to provide welders with a versatile and efficient work surface. The strategically placed holes allow for easy clamping and positioning of workpieces, making it easier to achieve precise and accurate welds. This is especially beneficial for complex welding projects that require meticulous attention to detail. With the new welding table top, welders can expect improved productivity and a higher level of precision in their work.In addition to its practical design, the welding table top is constructed from high-quality materials that ensure durability and longevity. This means that welders can rely on the table top to withstand the demands of daily use in a workshop environment. The robust construction also contributes to the overall safety of the welding process, providing a stable and secure work surface for welders to operate on.{Remove brand name} understands the diverse needs of welders, and their welding table top with holes is designed to accommodate a wide range of welding applications. Whether it's metal fabrication, automotive repair, or general welding tasks, the table top offers the flexibility and support needed to tackle various projects with ease. This versatility makes it a valuable asset for welding professionals across different industries and skill levels.Furthermore, the welding table top is compatible with a range of accessories and attachments, allowing welders to customize their work surface to suit their specific requirements. This adaptability is a key feature that sets the {remove brand name} welding table top apart from traditional welding tables, giving welders the freedom to optimize their workspace for maximum efficiency and convenience.To complement the launch of the new welding table top, {remove brand name} is also offering comprehensive training and support for welders who wish to integrate the table top into their workflow. This includes hands-on demonstrations, technical guidance, and resources to help welders make the most of their investment. By providing the necessary tools and expertise, {remove brand name} is dedicated to empowering welders and enhancing their capabilities in the workshop.In conclusion, the release of the new welding table top with holes from {remove brand name} marks a significant development in the welding industry. With its practical design, durable construction, and versatile features, the table top is poised to elevate the standards of welding workmanship. As {remove brand name} continues to push the boundaries of innovation, welders can look forward to a future of enhanced productivity and precision in their craft.

High-Quality Steel Wedge Plug for Various Industrial Applications

Wedge Steel Plug is a leading manufacturer and distributor of high-quality steel plugs. The company has been serving the industry for over two decades, providing top-notch products to customers around the globe. With a strong commitment to quality and innovation, Wedge Steel Plug has earned a reputation for excellence in the industry.The company offers a wide range of steel plugs, including wedge plugs, taper plugs, and hex head plugs. These products are designed to provide a secure and reliable sealing solution for a variety of applications, including pressure vessels, pipelines, and hydraulic systems. Wedge Steel Plug's products are manufactured to the highest standards, ensuring durability and performance in even the most demanding environments.In addition to its extensive product line, Wedge Steel Plug also offers custom machining services to meet specific customer requirements. The company's team of experienced engineers and technicians works closely with customers to develop tailored solutions that meet their exact specifications. Whether it's a unique plug design or a specific material requirement, Wedge Steel Plug has the expertise and capabilities to deliver custom solutions that meet the most demanding technical requirements.Wedge Steel Plug takes great pride in its commitment to quality and customer satisfaction. The company's products undergo rigorous testing and inspection to ensure they meet the highest standards of performance and reliability. With a focus on continuous improvement, Wedge Steel Plug is constantly investing in technology and process enhancements to further enhance the quality and consistency of its products.Furthermore, Wedge Steel Plug is dedicated to providing exceptional customer service and support. The company's team of knowledgeable and responsive professionals is always available to assist customers with product selection, technical support, and any other inquiries they may have. With a customer-centric approach, Wedge Steel Plug strives to build lasting relationships with its clients, delivering not only top-quality products but also unmatched service and support.In line with its commitment to innovation, Wedge Steel Plug has recently introduced a new line of environmentally friendly steel plugs. These products are designed to minimize environmental impact while still delivering the same high level of performance and reliability. By incorporating sustainable materials and manufacturing processes, Wedge Steel Plug is demonstrating its dedication to corporate responsibility and environmental stewardship.As part of its ongoing growth and expansion, Wedge Steel Plug is also continuously seeking to expand its global reach. The company has established a strong network of distributors and partners around the world, allowing it to serve customers in diverse industries and regions. With a focus on understanding local market needs and providing tailored solutions, Wedge Steel Plug is well-positioned to continue its growth and success on a global scale.In conclusion, Wedge Steel Plug is a trusted and respected leader in the steel plug industry, known for its commitment to quality, innovation, and customer satisfaction. With a comprehensive product line, custom machining capabilities, and a focus on environmental responsibility, Wedge Steel Plug is well-positioned for continued success and growth in the years to come. For any inquiries or further information about Wedge Steel Plug and its products, please visit the company's website or contact its customer service team directly.

High-Quality Machine Spare Parts for Granite Machinery

Granite Machine Spare Parts is a leading provider of high-quality, precision-engineered machine spare parts for the granite industry. The company has been serving the industry for over 20 years and has established a reputation for excellence and reliability. With its comprehensive range of spare parts and dedicated team of professionals, Granite Machine Spare Parts is committed to delivering superior products and exceptional service to its clients.The company's extensive product line includes a wide variety of spare parts for granite cutting machines, polishing machines, and other equipment used in the granite industry. From cutting blades and polishing pads to bearings and drive belts, Granite Machine Spare Parts offers everything needed to keep machines running smoothly and efficiently. The company takes pride in providing reliable and durable spare parts that meet the highest industry standards, ensuring the continued productivity and success of its clients' operations.Granite Machine Spare Parts is dedicated to meeting the diverse needs of its clients, offering a range of customization options to accommodate specific machine requirements. The company's team of experienced engineers and technicians work closely with clients to understand their unique needs and develop tailored solutions to meet those needs. With a focus on innovation and continuous improvement, Granite Machine Spare Parts remains at the forefront of technological advancements in the industry, consistently striving to deliver cutting-edge products that exceed client expectations.In addition to its extensive product line, Granite Machine Spare Parts also provides comprehensive technical support and after-sales service to its clients. The company's team of expert technicians is available to offer guidance and assistance with spare parts installation, maintenance, and troubleshooting, ensuring that clients have the support they need to keep their operations running smoothly. With a commitment to customer satisfaction, Granite Machine Spare Parts is dedicated to building long-lasting relationships with its clients based on trust, reliability, and superior service.Over the years, Granite Machine Spare Parts has built a strong reputation for its unwavering commitment to quality, reliability, and customer service. The company has established itself as a trusted partner to granite industry professionals, providing them with the tools and resources they need to succeed in a competitive market. With a focus on precision engineering and innovation, Granite Machine Spare Parts is poised to continue leading the industry and setting new standards for excellence in the years to come.As the global demand for high-quality granite products continues to grow, Granite Machine Spare Parts remains dedicated to supporting the industry with best-in-class spare parts and technical expertise. The company's continued investment in research and development, along with its unwavering commitment to customer satisfaction, positions it as a leader in the industry. With a proven track record of delivering exceptional products and service, Granite Machine Spare Parts is well-equipped to meet the evolving needs of its clients and contribute to the continued success of the granite industry.

Durable and Reliable Welding Table for Your Workshop

Stronghold Welding Table is revolutionizing the welding industry with its innovative and high-quality products. The company has been in business for over 20 years and has established itself as a leader in the welding and fabrication equipment market.With a strong focus on durability, reliability, and precision, Stronghold Welding Table has become the go-to choice for professionals and hobbyists alike. The company's products are designed to withstand the toughest of welding projects, making them the ideal choice for any welding application.One of the company's most popular products is its welding table, which has been praised for its heavy-duty construction and versatile design. The table is made from high-quality materials and features a robust frame that can support heavy workpieces with ease. Its adjustable height and tilt capabilities make it a versatile tool for any welding project.The welding table also features a flat and smooth surface, which is essential for achieving precise and accurate welds. Its non-flammable tabletop material ensures safety and protection against sparks and heat, making it a reliable choice for any welding application.In addition to its welding table, Stronghold Welding Table also offers a wide range of other products, including welding clamps and fixtures, welding jigs, and welding accessories. Each product is designed to meet the highest standards of quality and performance, ensuring that customers can rely on them for years to come.What sets Stronghold Welding Table apart from its competitors is its commitment to innovation and customer satisfaction. The company invests heavily in research and development to continuously improve its products and develop new solutions for the welding industry. This dedication to innovation has earned Stronghold Welding Table a reputation for excellence and reliability.Moreover, Stronghold Welding Table takes pride in its exceptional customer service and support. The company's team of experts is always available to provide guidance and assistance to customers, ensuring that they have the best possible experience with their products. This commitment to customer satisfaction has earned Stronghold Welding Table a loyal and dedicated customer base.Stronghold Welding Table also emphasizes environmental sustainability in its operations. The company is committed to reducing its carbon footprint and minimizing waste through responsible manufacturing practices. This environmentally conscious approach has earned Stronghold Welding Table recognition as a leader in sustainable business practices within the welding industry.Looking ahead, Stronghold Welding Table is poised for continued success and growth. The company is constantly looking for new opportunities to expand its product line and reach new markets. With its unwavering dedication to quality, innovation, and customer satisfaction, Stronghold Welding Table is well-positioned to remain a top choice for professionals and hobbyists in the welding industry.In conclusion, Stronghold Welding Table is a company that is reshaping the welding industry with its high-quality and innovative products. With a strong focus on durability, reliability, and precision, the company has earned a reputation as a leader in the welding and fabrication equipment market. Through its commitment to excellence, innovation, and customer satisfaction, Stronghold Welding Table is poised for continued success and growth in the years to come.

Revolutionary Cast Iron T-Slotted Test Beds: A Game-Changer in Product Testing

Title: Enhanced Precision and Durability: Cast Iron T-Slotted Test Beds Revolutionize Engineering TestingIntroduction:In the world of engineering testing, accuracy and durability are paramount for achieving reliable results. The introduction of Cast Iron T-Slotted Test Beds, by a leading industry player, marks a significant breakthrough in engineering testing technology. These state-of-the-art test beds have set a new standard, providing engineers with unparalleled precision and durability.Cast Iron T-Slotted Test Beds:The Cast Iron T-Slotted Test Beds are designed as robust and rigid platforms, offering a multitude of benefits for engineering testing applications. Constructed from high-quality cast iron, these test beds provide exceptional stability, ensuring repeatable and accurate test results. Additionally, the use of cast iron minimizes vibration and absorbs shock, further enhancing precision.The integration of T-slots across the test beds' surface enables effortless customization and reconfiguration, allowing engineers to adapt the test setup to their specific requirements. This feature simplifies the process of attaching and adjusting fixtures, instruments, and other testing components, saving both time and effort.Moreover, the Cast Iron T-Slotted Test Beds boast excellent heat dissipation capabilities. This characteristic is essential for thermal testing applications, enabling engineers to accurately evaluate the heat resistance of various components under different conditions. The ability to maintain a stable temperature throughout the testing process ensures reliable and consistent results.Another notable advantage of these test beds is their resistance to wear and tear. The cast iron body is highly durable, capable of withstanding heavy loads and extreme testing conditions. Their exceptional longevity significantly reduces maintenance costs, making them a cost-effective solution for organizations.Furthermore, the versatility of Cast Iron T-Slotted Test Beds makes them suitable for a wide array of testing purposes, including mechanical, electrical, and material testing. Engineers across various industries, such as automotive, aerospace, and manufacturing, can benefit from the precision and durability provided by these exceptional test beds.Company's Commitment to Excellence:{} is a renowned industry leader known for its commitment to delivering cutting-edge solutions. With decades of experience and a team of highly skilled professionals, the company has established itself as a trusted provider of testing equipment across the globe.The introduction of Cast Iron T-Slotted Test Beds reflects the company's dedication to innovation and continuous improvement. Quality is at the heart of their manufacturing process, ensuring that every test bed conforms to the highest industry standards. Rigorous quality control measures are implemented at every stage, from raw material selection to final product inspection, to guarantee optimal performance and reliability.In addition to providing world-class equipment, the company also offers comprehensive technical support to its customers. Their team of experts is available to guide engineers through the setup and maintenance of the test beds, ensuring smooth operations and maximum efficiency. This commitment to customer satisfaction sets {} apart, establishing them as an industry leader.Conclusion:The game-changing introduction of Cast Iron T-Slotted Test Beds revolutionizes engineering testing, elevating precision and durability to unprecedented levels. These cutting-edge test beds offer engineers a solid foundation for conducting a diverse range of tests, improving overall testing accuracy and cost-effectiveness.With {} leading the way, the future of engineering testing looks bright. Their commitment to innovation and customer satisfaction has successfully propelled them to the forefront of the industry. By continuously pushing boundaries and delivering state-of-the-art solutions, {} ensures that engineers worldwide can conduct precise and reliable testing, ultimately leading to advancements in technology and industry.