High Quality Granite for Use in Master Square Settings

By:Admin

The new processing facility is strategically located in close proximity to several granite quarries, allowing Master Square Granite to directly source the raw material for its products. This vertical integration will not only streamline the production process but also ensure a steady supply of high-quality granite for the company's extensive product line.

With a focus on sustainability and environmental responsibility, Master Square Granite has incorporated cutting-edge technology into the new facility to minimize waste and optimize energy usage. The company is committed to reducing its ecological footprint while maintaining its commitment to delivering top-notch products to its customers.

"We are thrilled to announce the opening of our new processing facility," said the CEO of Master Square Granite. "This strategic expansion will enable us to further enhance the quality and efficiency of our operations, while also allowing us to explore new opportunities for growth and innovation within the industry."

In addition to the state-of-the-art processing capabilities, the new facility will also feature a dedicated research and development center, where the company's team of experts will work on developing new products and optimizing existing ones. This investment in research and development reflects Master Square Granite's commitment to staying at the forefront of innovation and providing customers with the best possible solutions for their stone needs.

Master Square Granite has a long history of delivering top-notch stone products to a wide range of customers, including architects, designers, contractors, and homeowners. The company offers an extensive selection of granite products, including countertops, flooring, cladding, and custom stonework. Each product is meticulously crafted to meet the highest standards of quality and durability, making Master Square Granite a trusted choice for both residential and commercial projects.

The expansion of the processing facility is expected to have a significant impact on the local economy, creating job opportunities and supporting the growth of the region's stone industry. Master Square Granite is committed to being a responsible corporate citizen and aims to make a positive contribution to the communities in which it operates.

As the demand for premium stone products continues to grow, Master Square Granite's expansion comes at a pivotal time. By investing in cutting-edge technology and infrastructure, the company is poised to meet the evolving needs of the market and maintain its position as a leader in the stone industry.

With the opening of the new processing facility, Master Square Granite is well-positioned to continue delivering exceptional products and services to its customers while driving innovation and sustainability within the industry. The company's dedication to excellence and its forward-thinking approach ensure that it will remain a trusted partner for all stone-related needs.

Company News & Blog

Innovative 3D Welding Fixture System Revolutionizing Manufacturing Processes

We are pleased to announce that 3D Welding Fixture Systems are revolutionizing the welding industry. These advanced systems have been developed by a leading engineering company, which has a solid reputation for innovation and excellence in the field of industrial manufacturing.The 3D Welding Fixture System offers a high level of precision and accuracy, allowing for the creation of complex weldments with ease. It is equipped with advanced software that enables the user to design and simulate welding processes in a virtual environment, ensuring that the final product meets the highest standards of quality and reliability. This advanced technology also allows for real-time monitoring and adjustment of welding parameters, resulting in improved efficiency and cost savings.The system is designed to be easy to use, with an intuitive interface that allows for quick and simple setup. The modular design of the fixtures allows for adaptability to various welding applications, making it a versatile and practical solution for a wide range of manufacturing needs. With its advanced features and capabilities, the 3D Welding Fixture System is setting a new standard for welding excellence.In addition to its technical capabilities, the company behind the 3D Welding Fixture System has a strong commitment to customer satisfaction. They offer comprehensive training and support services to ensure that users are able to maximize the potential of their systems. Their team of highly skilled engineers and technicians are always available to provide assistance and guidance, making sure that their customers are able to achieve the best results with their systems.Furthermore, the company has a strong focus on continuous improvement and innovation. They are constantly pushing the boundaries of what is possible in the field of industrial manufacturing, and are dedicated to developing new and advanced solutions to meet the evolving needs of their customers. With their in-depth knowledge and expertise, they are well positioned to lead the way in the development of cutting-edge technology for the welding industry.The 3D Welding Fixture System is just one example of the company’s commitment to excellence and innovation. They have a proven track record of delivering high-quality products and services that exceed the expectations of their customers. With a strong emphasis on research and development, they are continuously striving to push the boundaries of what is possible in the field of industrial manufacturing.As the global manufacturing industry continues to evolve and grow, it is essential for companies to invest in advanced technology that can help them stay ahead of the competition. The 3D Welding Fixture System is a prime example of how innovative technology can revolutionize traditional manufacturing processes. With its advanced capabilities and user-friendly design, it is sure to be a game-changer for the welding industry.In conclusion, the 3D Welding Fixture System is an advanced and innovative solution that is shaping the future of welding technology. With its advanced features, user-friendly design, and strong emphasis on customer satisfaction, it is sure to set a new standard for excellence in the field of industrial manufacturing. The company behind this cutting-edge technology is dedicated to continuous improvement and innovation, and is well positioned to lead the way in the development of advanced solutions for the welding industry.

Quality Granite for Your Master Square Projects

Master Square Granite Announces Expansion Plans in Response to Growing DemandMaster Square Granite, a leading player in the stone and granite industry, has announced plans for a significant expansion to meet the growing demand for their products and services. The company has been gaining attention in the market for its high-quality granite and stone products, and the expansion is seen as a strategic move to capitalize on this momentum.Founded in 2005, Master Square Granite has built a strong reputation for delivering top-notch stone and granite solutions to a diverse range of clients, including homeowners, builders, and architects. The company has established itself as a trusted partner in the industry, known for its commitment to quality, innovation, and customer satisfaction.The recent surge in demand for Master Square Granite's products and services can be attributed to several factors, including the rising construction and renovation activities in the region. As more homeowners and businesses seek to enhance the aesthetics and functionality of their spaces, the demand for premium granite and stone solutions has grown significantly. Additionally, the company's focus on sustainable and environmentally friendly practices has resonated with a growing number of clients who prioritize eco-conscious options.In light of this increasing demand, Master Square Granite has outlined a comprehensive expansion plan that encompasses several key aspects of their operations. One of the primary components of the expansion is the investment in state-of-the-art manufacturing and processing equipment, which will enable the company to enhance its production capabilities and deliver even higher quality products to its customers.Furthermore, the expansion will involve the addition of new facilities and production sites to accommodate the growing volume of orders. By expanding its physical footprint, Master Square Granite aims to streamline its operations and improve efficiency, ultimately leading to shorter lead times and enhanced customer satisfaction. The company's commitment to providing a seamless and hassle-free experience for its clients is evident in this strategic decision to expand its infrastructure.In addition to the expansion of its manufacturing and production capabilities, Master Square Granite also plans to bolster its research and development efforts. With a focus on innovation and continuous improvement, the company aims to stay ahead of the curve in terms of product development and technological advancements in the industry. By investing in R&D, Master Square Granite seeks to introduce new, cutting-edge products that offer unique aesthetic and functional benefits to its customers.The expansion plans also include an emphasis on strengthening the company's distribution network and sales channels. By forging strategic partnerships and collaborations with distributors and retailers, Master Square Granite aims to extend its reach and make its products more accessible to a wider audience. This move aligns with the company's vision of becoming a leading provider of premium stone and granite solutions on a national and international scale.As Master Square Granite gears up for this significant expansion, the company's leadership remains committed to upholding its core values of integrity, excellence, and customer-centricity. The team at Master Square Granite is dedicated to maintaining the highest standards of quality in all aspects of its operations, from sourcing the finest raw materials to delivering exceptional customer service. This unwavering dedication to excellence has been a key driver of the company's success thus far and will undoubtedly continue to propel it forward as it embarks on this new phase of expansion.In conclusion, Master Square Granite's expansion plans mark a significant milestone in the company's journey to solidify its position as a leading player in the stone and granite industry. With a focus on enhancing its production capabilities, driving innovation, and expanding its market presence, Master Square Granite is poised to meet the growing demand for its products and services while maintaining its unwavering commitment to quality and customer satisfaction. The company's expansion is a testament to its resilience, adaptability, and long-term vision, and it is sure to herald a new era of growth and success for Master Square Granite.

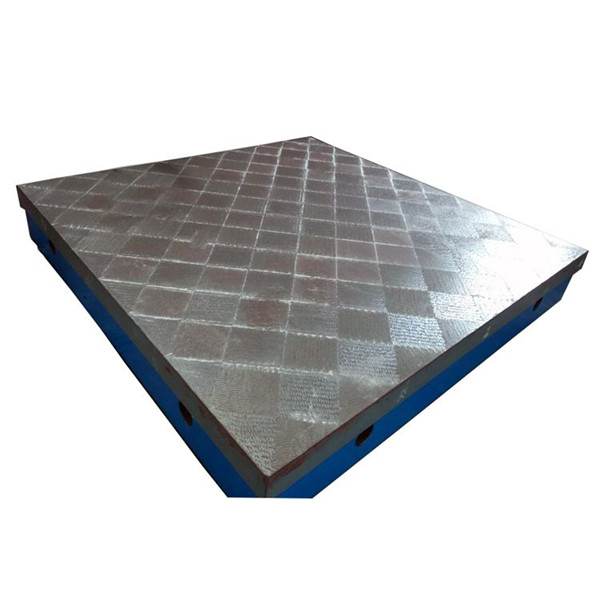

Maintaining Precision of Used Cast Iron Surface Plates with Routine Restoration

Keeping Precision Restoration for Your Used Cast Iron Surface PlateCast iron precision surface plates are essential tools widely used in the manufacturing industry. Their importance lies in their ability to provide accurate and level surfaces to measure and inspect various mechanical parts. However, with prolonged use, these plates can experience wear and tear, leading to a decrease in surface precision.Half Yearly InspectionOne way to keep your cast iron surface plate in top-notch condition is by performing regular inspections. After using the plate for half a year, it's essential to inspect the plate's surface precision to ensure it aligns with industry standards. You can use various measuring instruments such as micrometers, dial gauges, and straight edges to assess the surface's flatness, parallelism, and roughness.If your inspection reveals that the precision is not up to standard, you should consider repairing the plate rather than continuing to use it in its current condition. Minimum surface specifications dictate that the surface should be within 2-5 microns in flatness and no more than 0.03 mm in parallelism. Failure to maintain the recommended measurements may result in inaccurate readings, leading to faulty production and delayed projects.Restoration TechniquesVarious techniques can be used to restore your cast iron precision surface plate's surface. One common method is to scrape the surface to remove any high spots on the surface, which could lead to inaccuracy. Skilled technicians use scraping tools to level the plate uniformly, achieving the required flatness levels. The technicians then repeat the surface inspection to ensure that the plate meets the required standards.Another restoration technique involves the use of a milling machine, which grinds down any high spots on the surface. This method is effective when used on larger plates that cannot be scraped because it is time and labor-intensive. Other restoration techniques that can be used include lapping, planing, and the use of abrasives.Preventive MeasuresWhile restoration techniques can give your cast iron precision surface plate a new lease of life, it's essential to implement preventive steps to avoid the wear and tear that necessitates the restoration in the first place. Some of the measures you can take include:- Proper Care and Maintenance: A simple yet effective solution to prolonging the life of your cast iron surface plate is proper care and maintenance. This includes cleaning the surface regularly, using protective covers, avoiding dropping heavy objects on the plate, and storing the plate in a dry environment.- Re-Calibration: Regular re-calibration of the surface plate using one or more dependable master lengths and inspection instruments will help identify when the surface plate requires professional calibration.- Avoid Corrosion: Cast iron surface plates are susceptible to rust and corrosion, which can cause surface irregularities. You can avoid this by applying a protective coating to the surface to prevent moisture buildup. Waxing is one more way to avoid this!In ConclusionProper maintenance practices and regular inspection of your cast iron precision surface plate will not only prolong its life span but also improve the accuracy of the measurements taken on it. It is important to note that restoring the plate's surface should only be carried out by a skilled technician as the process requires accuracy and precision. Always ensure that your cast iron surface plate is in top condition before using it to avoid faulty production and unnecessary delays in your projects.

How to Use a V Block Professional for Granite Cutting

Innovative V-Block Precision Tool Revolutionizes Manufacturing IndustryIn a world where precision and accuracy are paramount, the manufacturing industry is constantly seeking out new and innovative technologies to improve efficiency and quality. This search has led to the development of the groundbreaking V-Block Precision Tool, a product that is set to revolutionize the industry.The V-Block Precision Tool is a state-of-the-art device that is designed to provide high-precision measurement and alignment for a wide range of applications. With its unique granite construction and precision-machined surfaces, this tool offers unparalleled stability and accuracy, making it an essential addition to any manufacturing operation.The V-Block Precision Tool is the brainchild of a cutting-edge company that has been at the forefront of precision measurement and alignment technology for over two decades. Their dedication to innovation and quality has made them a trusted leader in the industry, and the development of the V-Block Precision Tool is yet another testament to their commitment to excellence.This company has a long-standing reputation for delivering top-notch products and services to their clients across various industries. With a team of expert engineers and technicians, they have consistently demonstrated their ability to push the boundaries of what is possible in precision measurement and alignment.The V-Block Precision Tool is the result of extensive research and development, and it has been engineered to meet the highest standards of quality and performance. Its granite construction provides exceptional stability and durability, ensuring that it can withstand the rigors of industrial use while maintaining its precision and accuracy.One of the key features of the V-Block Precision Tool is its versatility. It can be used in a wide range of applications, from machining and assembly to inspection and testing. This versatility makes it an invaluable tool for any manufacturing operation, allowing for quick and accurate measurement and alignment across various processes.In addition to its precision and versatility, the V-Block Precision Tool also offers unmatched ease of use. Its intuitive design and user-friendly interface make it accessible to operators of all skill levels, allowing them to take full advantage of its capabilities without the need for extensive training or expertise.The introduction of the V-Block Precision Tool is set to bring about a significant shift in the manufacturing industry. Its ability to provide high-precision measurement and alignment in a wide range of applications will streamline processes, improve efficiency, and ultimately lead to higher-quality products.Furthermore, the V-Block Precision Tool is poised to have a positive impact on the bottom line for manufacturing operations. By reducing the time and resources required for measurement and alignment, it will help to lower production costs and increase overall productivity, ultimately leading to improved competitiveness in the market.The unveiling of the V-Block Precision Tool is a significant milestone for the company behind it, and it serves as a reminder of their ongoing commitment to innovation and excellence. With this groundbreaking product, they are once again demonstrating their ability to push the boundaries of what is possible in precision measurement and alignment.In conclusion, the V-Block Precision Tool is a game-changer for the manufacturing industry. Its unparalleled stability, accuracy, versatility, and ease of use make it an essential tool for any manufacturing operation seeking to improve efficiency and quality. With the introduction of this groundbreaking product, the company behind it is reaffirming its position as a leader in precision measurement and alignment, and is setting a new standard for the industry as a whole.

Durable and Strong Machine Base Made of Casting Iron

Casting Iron Machine Base, a leading manufacturer of high-quality machine bases and components, has recently announced the launch of their latest product designed to meet the growing demands of the industry. The new machine base is set to revolutionize the manufacturing sector by providing exceptional stability, durability, and precision for various industrial applications.Established in [year], Casting Iron Machine Base has been at the forefront of the industry, delivering superior products and services to their clients worldwide. With a strong focus on innovation and excellence, the company has continuously raised the bar in terms of quality and performance, setting new standards within the manufacturing sector.The newly introduced machine base boasts a state-of-the-art design, meticulously engineered to offer unparalleled strength and rigidity. Constructed from high-quality cast iron, the base provides a stable foundation for a wide range of industrial machines, including lathes, milling machines, grinders, and more. The robust construction of the base ensures vibration dampening and enhanced cutting precision, resulting in higher productivity and superior finished products.Furthermore, the precision machining of the base guarantees tight tolerances and excellent flatness, contributing to consistent and accurate machining operations. This level of accuracy is crucial in today's manufacturing environment, where even minor deviations can lead to costly errors and production delays. By investing in the new machine base from Casting Iron Machine Base, manufacturers can expect to achieve higher levels of efficiency and product quality, ultimately gaining a competitive edge in the market.In addition to its superior engineering, the machine base is designed to withstand heavy loads and harsh working conditions, making it suitable for diverse industrial settings. Whether in a busy production facility or a rigorous machining environment, the durability of the machine base ensures long-term reliability and performance, minimizing downtime and maintenance costs for the end-users."We are thrilled to introduce our latest machine base to the market," said [Spokesperson's Name], the CEO of Casting Iron Machine Base. "At Casting Iron Machine Base, we are committed to empowering manufacturers with the tools they need to succeed. The new machine base exemplifies our dedication to quality and innovation, and we are confident that it will make a significant impact on our customers' operations."As a company with a strong emphasis on customer satisfaction, Casting Iron Machine Base offers customizable solutions to meet specific industry requirements. Clients can work closely with the company's team of experts to tailor the machine base according to their unique needs, ensuring seamless integration into their existing machinery and production processes.Moreover, Casting Iron Machine Base provides comprehensive technical support and after-sales services, demonstrating their ongoing commitment to client success. With a global presence and a reputation for excellence, the company is well-positioned to serve the needs of manufacturers across various sectors, including automotive, aerospace, metalworking, and beyond.The introduction of the new machine base further solidifies Casting Iron Machine Base's position as an industry leader, driving innovation and progress within the manufacturing sector. As technology continues to evolve and demand for precision machining rises, the company remains dedicated to pioneering solutions that empower manufacturers to thrive in a competitive market landscape.For more information about Casting Iron Machine Base and their range of products, visit their website at [website]. With a legacy of delivering quality and performance, the company stands as a trusted partner for manufacturers seeking cutting-edge solutions for their industrial needs.

Top-rated Welding Table with Exceptional Features Offered for Welding Professionals

Title: Premium Welding Table Revolutionizes Welding Industry StandardsIntroduction:Welding is a critical process in various industries such as construction, automotive, and manufacturing. To ensure precision and efficiency in welding, it is essential to have a reliable and sturdy welding table. However, until now, professionals have faced numerous challenges due to the lack of innovative solutions in the market.In light of this, a leading welding equipment manufacturer has introduced a revolutionary Professional Welding Table that has set new standards in the industry. This groundbreaking product has garnered significant attention for its exceptional features, durability, and unmatched performance. Designed to meet the evolving needs of welders worldwide, the Professional Welding Table has quickly become a game-changer in the welding community.Feature 1: Innovative Design and ConstructionThe Professional Welding Table boasts an innovative design that ensures optimal stability and functionality. Crafted from high-quality materials, its robust construction allows welders to work with heavy metal components without any concern for the table's structural integrity. The table's ergonomic layout enhances precision during the welding process, enabling welders to achieve superior results.Feature 2: Versatility and CustomizationUnderstanding the diverse requirements of welders, the Professional Welding Table offers exceptional versatility. It includes a modular system that allows users to easily attach various accessories, such as clamps, jigs, and fixtures, enabling adaptable work setups. This flexibility ensures that professionals can complete a wide range of welding projects with ease and efficiency.Feature 3: Advanced Technology IntegrationThe Professional Welding Table integrates cutting-edge technology to enhance workflow and productivity. Equipped with state-of-the-art welding automation systems, it enables precise control over welding parameters, ensuring consistent and high-quality welds. The utilization of advanced plasma and laser cutting machines aids in shaping and preparing metal components for welding, further streamlining the welding process.Feature 4: Enhanced Safety MeasuresSafety is paramount in any welding operation, and the Professional Welding Table addresses this crucial aspect. To prevent unwanted accidents, the table includes built-in safety features such as anti-spatter coatings, heat-resistant surfaces, and grounding mechanisms. These measures significantly reduce the risk of injuries and fires caused by sparks or stray currents, providing peace of mind to welders.Feature 5: Durability and LongevityThe Professional Welding Table is engineered to withstand the demands of rigorous welding tasks. With its corrosion-resistant surface and robust frame, it ensures long-term durability, making it a sound investment for welding professionals. The table's resistance to heat, excessive vibrations, and heavy loads ensures consistent performance, reducing downtime and maintenance costs.Company Introduction:As a renowned welding equipment manufacturer, our company has always been committed to delivering cutting-edge solutions that transform the welding industry. With decades of experience, we have developed a deep understanding of welders' needs and consistently strive to exceed their expectations.By combining our expertise with extensive research and development efforts, we introduced the Professional Welding Table to bridge the gap in the market. We take pride in designing top-of-the-line products that enhance welders' efficiency, precision, and safety.Our commitment to quality and innovation has earned us a stellar reputation in the industry. We continually invest in the latest technologies and manufacturing techniques to ensure that our products integrate seamlessly into various welding processes. Welders worldwide trust our brand for its reliability, durability, and consistent performance.Conclusion:The release of the Professional Welding Table marks a significant milestone in the welding industry, redefining the standards for welding equipment. Its innovative design, advanced features, and sturdy construction empower welders to achieve unmatched precision and efficiency in their work.By integrating the latest technologies and prioritizing safety measures, the Professional Welding Table enables professionals to carry out their tasks with confidence and peace of mind. This remarkable product truly caters to the evolving needs of welders and has quickly become an indispensable tool in the welding community.As the leading welding equipment manufacturer, our company remains committed to pushing the boundaries of welding technology, ensuring that welders worldwide have access to top-quality solutions that revolutionize their craft.

Easily Restore Your Blades with a High-precision Flat Surface Plate

, Cool Tools, Super Flat, Stone, Sharpening, Edge RestorationAre you tired of uneven, dull edges on your knives and other cutting tools? Look no further than the Granite Surface Plate from Cool Tools for super flat, precise edge restoration.Made from high-quality granite, this surface plate is incredibly durable and resistant to wear and tear. It's also easy to clean and maintain, with a non-porous surface that won't absorb any liquids or debris.But what really sets the Granite Surface Plate apart is its super flat surface. This makes it perfect for use in sharpening and restoring the edges of your tools, as any imperfections or unevenness in the surface can negatively affect the results.Using the Granite Surface Plate is simple. Just lay your tool on the surface, and use a sharpening stone or other edge restoration tool to work on the blade. The super flat surface ensures that you're working on a precise edge, and the hardness of the granite means that the plate won't wear down over time.Of course, the Granite Surface Plate isn't just great for sharpening. It can also be used for a variety of other tasks, such as measuring and inspecting. And because it's so versatile, it's a must-have for any serious DIYer or craftsman.So if you're tired of frustratingly uneven edges on your tools, check out the Granite Surface Plate from Cool Tools. With its super flat surface and unmatched durability, it's the perfect tool for any job that requires precision and accuracy.

Durability and Strength: Choosing the Right Machine Base for Your Needs

Casting Iron Machine Base Optimizes Production Processes for Various IndustriesMetalwork technology has played a pivotal role in the advancement of manufacturing processes. One of the key components in this technology is the casting iron machine base, a fundamental part of machinery used in industries such as automotive, aerospace, and construction. These bases provide a strong and stable foundation for machinery, ensuring precision and reliability in manufacturing processes. In this article, we will explore the significance and advantages of casting iron machine bases, as well as their applications across different industries.A casting iron machine base serves as a robust support structure for a wide range of machines, including lathes, milling machines, and grinding machines. It is made from ductile or gray cast iron, which possesses excellent mechanical properties, such as high tensile strength, wear resistance, and vibration damping capabilities. The precise construction of these bases ensures minimal distortion under heavy loads, contributing to accurate and consistent machining operations.The cost-effectiveness and reliability of casting iron machine bases have made them an integral component in various industries. In the automotive sector, these bases form the backbone of assembly lines, providing a stable platform for robotic arms and conveyor systems. The aerospace industry heavily relies on casting iron machine bases for the production of aircraft parts with critical tolerances. Moreover, construction companies employ these bases to support heavy machinery used in building structures, such as cranes and excavators.The company X, renowned for their expertise in manufacturing casting iron machine bases, has been a leading provider to industries globally. Their commitment to quality and innovation has resulted in the development of cutting-edge products that enhance manufacturing efficiency. With years of experience and a team of skilled engineers, X has become a trusted partner for companies seeking reliable machine bases.X employs advanced casting techniques to ensure the highest level of precision and consistency in their products. The casting process begins with meticulous pattern-making, followed by mold preparation. Molten iron is then poured into the mold, and once cooled, the base undergoes various finishing operations to achieve the desired surface texture. X's stringent quality control measures guarantee that every base meets the industry's stringent standards.To accommodate the diverse needs of different industries, X offers custom-made casting iron machine bases. Their engineering team collaborates closely with clients to understand specific requirements and design bases that optimize performance for each application. By tailoring the bases to customer needs, X empowers companies to enhance their manufacturing processes and achieve higher productivity.Additionally, X recognizes the significance of sustainable manufacturing practices. They strive to reduce their environmental impact by adopting eco-friendly approaches throughout the production process. With efficient resource management and waste reduction strategies, X ensures that their casting iron machine bases are manufactured in an environmentally responsible manner.The future holds promising opportunities for the casting iron machine base market. As industries continue to evolve and demand higher precision in manufacturing, the need for reliable and durable machine bases will persist. X remains at the forefront of this industry, continually investing in research and development to introduce new technologies and enhancements that benefit their customers.In conclusion, casting iron machine bases are essential components in a wide range of industries, offering stability, precision, and durability to manufacturing processes. X's expertise and commitment to quality have established them as a leading manufacturer of these bases, serving numerous industries worldwide. By prioritizing customer requirements and employing sustainable practices, X ensures that their casting iron machine bases not only optimize production processes but also contribute to a greener future.

Durable and Versatile Welding Bench for Your Workstation

The welding industry is constantly evolving, with new technologies and equipment constantly being developed to meet the growing needs of the market. One such innovation is the welding bench, a versatile piece of equipment that is essential for any welding project.Today, we are pleased to introduce the new welding bench from {Company Name}. This bench is designed to provide a stable and secure work surface for all types of welding activities, from simple repairs to complex fabrications. With its durable construction and adjustable features, the {Company Name} welding bench is a valuable addition to any welding workshop.The {Company Name} welding bench is built to withstand the demands of daily use in a professional welding environment. Its heavy-duty steel construction provides a sturdy foundation for welding tasks, while its adjustable height and angle capabilities allow for a comfortable working position for welders of all sizes. The bench also features a spacious work area with a non-slip surface, providing ample space for welding components and tools.In addition to its practical design, the {Company Name} welding bench is also equipped with a range of useful features to enhance productivity and efficiency. Integrated clamps and vices enable secure positioning of workpieces, while built-in tool storage and accessory holders keep essential items within easy reach. The bench is also compatible with a range of welding accessories, such as magnetic clamps and welding jigs, to further expand its functionality.With the {Company Name} welding bench, welders can work with confidence, knowing that they have a reliable and durable work surface to support their projects. Whether working on small-scale repairs or large-scale fabrications, this versatile bench is well-suited to a wide range of welding tasks. Its robust construction and adjustable features make it an invaluable asset for any welding workshop.At {Company Name}, we are committed to providing high-quality welding equipment that meets the needs of our customers. The introduction of the {Company Name} welding bench reflects our dedication to innovation and excellence in the welding industry. We understand the demands of professional welding work, and our products are designed to meet those demands with efficiency and reliability.In addition to the welding bench, {Company Name} offers a comprehensive range of welding equipment and accessories to support a variety of welding applications. From welding machines and protective gear to cutting tools and consumables, we have everything welders need to complete their projects with precision and confidence. Our commitment to quality and customer satisfaction sets us apart as a leading supplier of welding solutions.As the welding industry continues to advance, the demand for reliable and efficient equipment will only grow. The {Company Name} welding bench is a testament to our ongoing efforts to meet that demand, providing welders with a dependable and versatile work surface that enhances their productivity and performance. With its durable construction, practical features, and compatibility with a range of accessories, the {Company Name} welding bench is poised to become an essential tool for welding professionals everywhere.

Top 5 Best Adjustable Welding Tables for 2022: Buyer's Guide

Adjustable Welding Table Revolutionizes Industrial WeldingIndustrial welding is an essential process used in various manufacturing and construction industries. It requires precision and efficiency to ensure the quality and structural integrity of the final product. To meet the demands of this important task, a new product has been introduced to the market that is set to revolutionize the way industrial welding is performed. The Adjustable Welding Table by {company name} is a game-changer in the welding industry, offering unparalleled versatility and functionality.{Company name} has been a leading manufacturer of industrial equipment for over two decades. With a commitment to innovation and quality, the company has built a strong reputation for delivering reliable and high-performance products. The introduction of the Adjustable Welding Table is another testament to the company's dedication to meeting the needs of the industry and its customers.The Adjustable Welding Table is designed to provide welders with a stable and adaptable work surface that can accommodate a wide range of welding tasks. The table features a sturdy steel construction, ensuring durability and reliability in the most demanding work environments. Its adjustable height and tilt angles enable welders to work comfortably and efficiently, reducing strain and fatigue during long welding sessions.One of the key features of the Adjustable Welding Table is its modular design, which allows for easy customization and expansion. The table can be equipped with various accessories such as clamps, vices, and extension wings, providing additional support and flexibility for different welding projects. This level of adaptability makes the table suitable for a wide range of applications, from small-scale fabrication to large-scale production.In addition to its versatility, the Adjustable Welding Table also incorporates advanced safety features. The table is equipped with built-in fume extraction and filtration systems, ensuring a clean and safe work environment for welders. This not only protects the health and well-being of the workers but also contributes to a more sustainable and eco-friendly manufacturing process.The Adjustable Welding Table is also designed to enhance productivity and workflow efficiency. Its integrated power and air supply outlets enable welders to connect their tools and equipment directly to the table, eliminating the need for multiple power sources and extension cords. This streamlined setup minimizes clutter and tripping hazards in the workspace, allowing for a more organized and efficient welding process.The introduction of the Adjustable Welding Table has generated significant interest and excitement in the industry. Welders and fabricators across various sectors have expressed their anticipation for the new product, recognizing its potential to simplify and improve their work. With its innovative design and practical features, the table is expected to set a new standard for welding equipment and contribute to the advancement of industrial welding technology.{Company name} has announced that the Adjustable Welding Table will be available for purchase in the coming months, and pre-orders are already being accepted. The company has also committed to providing comprehensive training and support to ensure that customers can maximize the benefits of the new product. With its reputation for excellence and customer satisfaction, {company name} is well-positioned to lead the market with this groundbreaking innovation.The introduction of the Adjustable Welding Table marks a significant milestone for the welding industry, as it paves the way for a more efficient, safe, and productive welding process. {Company name}'s commitment to innovation and quality has once again delivered a product that is set to make a lasting impact in the industry. As the demand for high-quality welding equipment continues to grow, the Adjustable Welding Table stands out as a testament to the power of innovation and the potential for progress in industrial manufacturing.