High-Quality Machine Parts for Granite Cutting and Fabrication

By:Admin

Granite Machine Parts has been a trusted name in the manufacturing industry for over two decades. From its humble beginnings as a small workshop, the company has grown to become a leading provider of precision machine parts for a wide range of industries. With a commitment to quality, innovation, and customer satisfaction, Granite Machine Parts has continually sought to improve its manufacturing processes and capabilities.

Recently, Granite Machine Parts made a significant investment in new cutting-edge manufacturing technology, further solidifying its position as a leader in the industry. The company's latest acquisition includes state-of-the-art machining equipment and advanced software that will allow for increased precision and efficiency in the production of machine parts.

The new technology will enable Granite Machine Parts to take on more complex and intricate projects, while also improving the overall quality and accuracy of its products. This investment is a testament to the company's dedication to staying at the forefront of technological advancements in the manufacturing sector.

"We are thrilled to introduce this new technology into our manufacturing process," said [company spokesperson]. "This investment represents our ongoing commitment to providing the highest quality machine parts to our customers. With this new equipment, we will be able to take on more challenging projects and deliver even greater precision and accuracy in our products."

The new machinery is equipped with advanced features such as multi-axis capabilities, high-speed cutting, and automated tool changing, allowing for faster and more precise manufacturing. Additionally, the accompanying software provides advanced modeling and simulation tools, which will streamline the design and production process, ultimately reducing lead times for customers.

Granite Machine Parts has always been known for its meticulous attention to detail and commitment to exceeding customer expectations. With the addition of this cutting-edge technology, the company is poised to further elevate its capabilities and deliver even greater value to its clients.

In addition to improving its manufacturing capabilities, Granite Machine Parts has also focused on enhancing its quality control processes. With the new technology, the company can more accurately inspect and verify the dimensions and specifications of each part, ensuring that they meet the highest standards of quality and precision.

"We believe that this investment will not only benefit our own operations, but also our customers, as they will receive even better products with improved lead times," [company spokesperson] added. "We are excited to see the positive impact this technology will have on our business and on the industries we serve."

Granite Machine Parts has always prided itself on its ability to adapt to the ever-changing demands of the manufacturing industry. The company's commitment to innovation, quality, and customer satisfaction has been the driving force behind its success, and this recent investment in cutting-edge technology is a testament to that commitment.

As Granite Machine Parts continues to grow and evolve, it remains dedicated to providing the highest quality machine parts and exceptional service to its customers. With its latest technological advancements, the company is well-positioned to continue leading the way in precision machining and manufacturing for years to come.

Company News & Blog

Discover the Benefits of Cast Iron in MAGMAinteract for Your Next Cooking Adventure" could be rewritten to "Explore the Advantages of Cast Iron for Your Next Culinary Experience.

Cast Iron V Blocks: Strength and Reliability for Precision MachiningWhen it comes to precision machining, the tools and fixtures used are just as important as the machines themselves. One of the most critical fixtures in machining is V blocks. These special blocks are designed to hold and support round or cylindrical parts during machining.Of all the materials available for making V blocks, cast iron is one of the most popular choices. In this blog, we'll explore the benefits of cast iron V blocks and why they are the ideal choice for precision machining.1. Strength and DurabilityCast iron is a strong and durable material that can withstand the rigors of heavy-duty machining. It is resistant to wear and tear and can handle high-temperature environments without warping or cracking.This makes cast iron V blocks ideal for long-term use and ensures that they will maintain their precision over time. The strength and durability of cast iron also mean that it can withstand the force of high-speed cutting without breaking or distorting.2. Excellent Vibration Damping PropertiesOne of the biggest challenges in precision machining is controlling vibration. Vibrations can negatively affect the part being machined, leading to poor surface finish and alignment issues.Cast iron has excellent vibration damping properties, which means that it can absorb vibrations and prevent them from affecting the machined part. This is crucial for achieving high-precision and high-quality parts.3. Dimensional StabilityCast iron has a high degree of dimensional stability, which means that it maintains its shape and size under varying temperature and humidity conditions. This makes it an ideal material for precision machining fixtures like V blocks, which need to maintain their accuracy across a range of working conditions.Cast iron V blocks are also resistant to expansion and contraction due to temperature changes, which ensures that they maintain their precise alignment with the machined surface.4. Low Coefficient of Thermal ExpansionCast iron has a low coefficient of thermal expansion, meaning that it expands and contracts relatively little as temperatures change. This makes it an ideal material for machining fixtures that need to maintain their precise dimensions across a range of operating temperatures.Cast iron V blocks are particularly useful in high-temperature machining applications. They can withstand the high temperature of cutting tools and prevent any expansion or distortion that could affect the accuracy of the machined parts.5. VersatilityCast iron is a versatile material that can be easily machined to produce a wide range of shapes and sizes. This makes it an ideal material for V blocks, which come in various sizes, from small blocks used for precision measurement to large blocks designed for holding heavy cylindrical parts.ConclusionIn conclusion, cast iron V blocks are an excellent choice for precision machining. Their strength, durability, vibration damping properties, dimensional stability, and low coefficient of thermal expansion make them ideal for high-precision machining applications.If you're looking for high-quality cast iron V blocks for your machining needs, look no further than MAGMAinteract. Our cast iron V blocks are made from the highest quality materials and are designed to provide the strength, reliability, and precision you need for the most demanding machining applications.

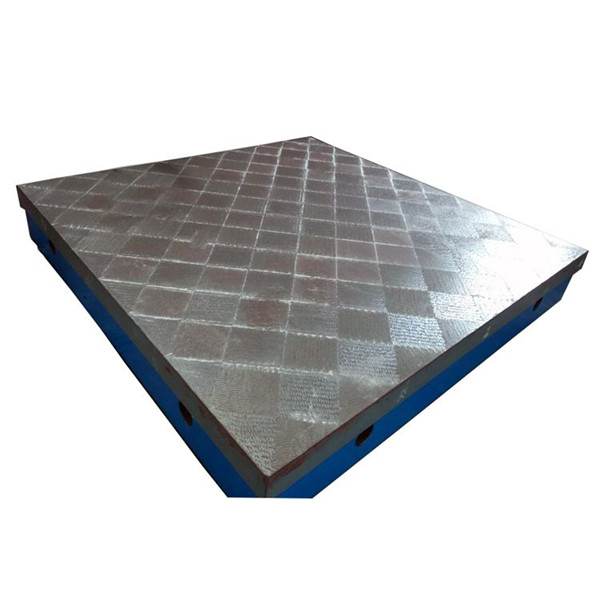

High Chromium White Iron Castings for Wear Resistance on Inspection Surface Plates - Affordable Prices Available from Manufacturers in China

Cast Iron Surface Inspection Plate Factory: The Importance of Quality InspectionWhen it comes to manufacturing and testing equipment, quality and precision are of the utmost importance. In industries such as automotive, aerospace, and construction, precise measurements and accurate testing are essential. This is where cast iron surface inspection plates come into play.Cast iron surface inspection plates are designed to provide a flat, stable, and smooth surface for use in measuring equipment and machinery. They are used for a variety of purposes, such as testing the accuracy of machines, checking the flatness of surfaces, and measuring the thickness of objects.But not all cast iron surface inspection plates are created equal. The quality of these plates can vary depending on the manufacturer and the materials used. This is why it is important to choose a reputable Cast Iron Surface Inspection Plate Factory.At a reputable factory, the plates are manufactured with high-quality materials and undergo rigorous testing and inspections to ensure they meet the highest standards. Casting is done in state-of-the-art facilities, and the composition of the iron is carefully controlled to ensure consistent quality.One of the key factors that affect the quality of cast iron surface inspection plates is the composition of the iron. High chromium white iron is used for wear-resistant castings, while cement polished board carbon and silicon content is low. Carbon mainly exists in cementite form, and the fracture surface is carefully analyzed to identify the manufacturing process and any potential defects.Another important factor to consider is the finishing of the plates. The surface must be perfectly flat and free from any defects or irregularities. Advanced techniques such as lapping and measuring ensure that the plates meet exacting standards.In addition to providing high-quality cast iron surface inspection plates, reputable factories also offer customized solutions to meet the specific needs of customers. This includes plates of different thicknesses, sizes, and shapes, as well as special coatings and finishes.In conclusion, choosing a reputable Cast Iron Surface Inspection Plate Factory is crucial for ensuring the highest quality and precision in manufacturing and testing equipment. With the right materials and manufacturing processes, cast iron surface inspection plates can provide the reliable and accurate measurements that industries depend on.

Durable Cast Iron Measuring Tools for Your Kitchen

Cast Iron Measuring Tools: The Reliable Solution for Industrial MeasurementsIn the world of industrial manufacturing, precision and accuracy are crucial components for success. It is essential for companies to have reliable and durable measuring tools that can withstand the rigors of daily use. That is where Cast Iron Measuring Tools come into play.Cast Iron Measuring Tools, manufactured by a leading industrial equipment company, are renowned for their quality, accuracy, and durability. These measuring tools are suitable for a wide range of industrial applications, including machining, metalworking, and engineering. The company has a long-standing reputation for producing high-quality industrial equipment, and their Cast Iron Measuring Tools are no exception.The Cast Iron Measuring Tools offered by the company include a variety of measuring instruments such as squares, protractors, calipers, and rulers. These tools are made from high-quality cast iron, which gives them the strength and stability required for precise measurements. The use of cast iron also ensures that the measuring tools are resistant to wear and tear, making them ideal for heavy-duty industrial use.One of the key features of the Cast Iron Measuring Tools is their accuracy. These measuring instruments are meticulously calibrated to provide precise measurements, ensuring that industrial processes are carried out with the highest level of precision. The company takes great pride in the accuracy of its measuring tools, which have been trusted by industrial professionals for many years.In addition to accuracy, the durability of the Cast Iron Measuring Tools is also a significant advantage. The robust nature of cast iron makes these measuring instruments highly resistant to corrosion and damage, allowing them to maintain their accuracy and reliability over extended periods of use. This durability makes the measuring tools a cost-effective investment for industrial businesses, as they can withstand the demands of a challenging work environment.Furthermore, the company's dedication to quality is evident in its manufacturing processes. Each Cast Iron Measuring Tool undergoes rigorous quality control measures to ensure that it meets the company's high standards. This commitment to quality has earned the company a strong reputation in the industrial equipment market, making its measuring tools a preferred choice for many professionals in the industry.The versatility of Cast Iron Measuring Tools is another reason for their popularity. These measuring instruments can be used in a wide range of industrial applications, making them an indispensable tool for professionals in various fields. Whether it's for precision machining, metal fabrication, or general engineering work, these measuring tools provide the accuracy and reliability that industrial businesses demand.The company also offers customization options for its Cast Iron Measuring Tools, allowing customers to tailor the instruments to their specific requirements. This flexibility ensures that businesses can acquire measuring tools that are perfectly suited to their individual needs, further enhancing the value that these instruments offer.In conclusion, Cast Iron Measuring Tools from the leading industrial equipment company are a reliable and durable solution for industrial measurements. With their exceptional accuracy, durability, and versatility, these measuring instruments are trusted by professionals across various industries. The company's commitment to quality and customer satisfaction has solidified its position as a trusted provider of industrial equipment, making its Cast Iron Measuring Tools a popular choice for businesses seeking reliable measuring solutions.

High-Quality Measuring Tool Manufacturer for Granite Products

Granite Measuring Tool Manufacturer, a leading company in the precision measurement industry, continues to uphold its legacy of producing high-quality and reliable granite measuring tools. With a rich history that spans over two decades, the company has established itself as a trusted provider of precision measuring instruments for various industries such as automotive, aerospace, and manufacturing.Founded in the early 1990s, Granite Measuring Tool Manufacturer initially focused on producing granite surface plates for industrial applications. Over the years, the company has expanded its product line to include granite squares, straight edges, parallels, and other precision measuring tools. This diversification has enabled the company to cater to a wider range of customer needs and solidify its position as a comprehensive provider of precision measurement solutions.One of the key factors that sets Granite Measuring Tool Manufacturer apart from its competitors is its unwavering commitment to quality. The company prides itself on using only the finest grade granite and adhering to stringent manufacturing processes to ensure the utmost precision and accuracy of its products. This dedication to quality has earned the company a stellar reputation among its clients, who rely on Granite Measuring Tool Manufacturer's tools for critical measurement and inspection tasks.In addition to its focus on quality, Granite Measuring Tool Manufacturer places a strong emphasis on innovation and continuous improvement. The company regularly invests in research and development to stay at the forefront of technological advancements in the measurement industry. This proactive approach has resulted in the introduction of new and advanced products that meet the evolving needs of modern manufacturing and engineering processes.Furthermore, Granite Measuring Tool Manufacturer is committed to providing exceptional customer service and support. The company understands the importance of building strong relationships with its clients and works closely with them to deliver tailored solutions that meet their specific requirements. Whether it's providing customized measurement tools or offering technical guidance, Granite Measuring Tool Manufacturer prides itself on being a trusted partner to its customers.Looking ahead, Granite Measuring Tool Manufacturer is poised for continued growth and success in the precision measurement industry. The company's dedication to quality, innovation, and customer satisfaction has positioned it as a preferred choice for businesses seeking reliable measuring instruments. As industries continue to demand higher levels of precision and accuracy, Granite Measuring Tool Manufacturer is well-equipped to meet these challenges and remain a leader in the field.Granite Measuring Tool Manufacturer's commitment to excellence and its ability to adapt to changing market needs make it a formidable force in the precision measurement industry. With a solid foundation built on quality, innovation, and customer-centric values, the company is well-positioned to thrive in the years to come. As technology and industry standards continue to evolve, Granite Measuring Tool Manufacturer is ready to embrace the future and continue its legacy of providing best-in-class precision measuring tools.

High-quality Surface Inspection Plates: A Look into the Cast Iron Factory

Cast Iron Surface Inspection Plate Factory, a leading manufacturer of high-quality surface inspection plates, has been serving the industry for many years with its dedication to providing durable, accurate and reliable products. The factory specializes in the production of cast iron surface inspection plates, also known as surface plates or layout plates, which are essential in a variety of industries such as metalworking, manufacturing, automotive and aerospace.The factory is equipped with state-of-the-art machinery and a team of skilled technicians, who ensure that each surface inspection plate meets the highest standards of quality and precision. The factory's range of products includes standard and custom-made surface plates in various sizes, designs and configurations to suit the specific needs of its customers. The factory also offers customization services to meet the unique requirements of its clients.In addition to manufacturing, the factory is also committed to providing excellent customer service by offering technical support, after-sales service and timely delivery of products. The factory's dedication to quality and customer satisfaction has earned it a solid reputation within the industry, making it a trusted partner for businesses around the world.The factory's cast iron surface inspection plates are known for their durability, stability and accuracy, making them an ideal choice for various applications such as precision measurement, layout, inspection, and assembly work. The plates are made from high-quality cast iron, which is known for its excellent wear resistance, stability, and ability to maintain accuracy over time. This makes them a reliable tool for ensuring precision and consistency in the production process.Furthermore, the factory's surface inspection plates are designed to withstand heavy-duty use in harsh industrial environments, making them a cost-effective investment for businesses looking for long-term reliability and performance. Whether used in a machine shop, laboratory, or production floor, the factory's surface plates provide a stable and level surface for carrying out accurate measurements, inspections, and assembly work.One of the key advantages of using cast iron surface inspection plates from the factory is their ability to provide a reference surface that is resistant to wear, corrosion, and distortion. This ensures that measurements and inspections are performed with high accuracy and repeatability, leading to improved product quality and reduced rework. The plates also feature precision-ground surfaces with carefully finished edges, providing a smooth and flat working area for various applications.The factory's commitment to excellence extends to its manufacturing processes, which are carried out in accordance with strict quality control standards to ensure that each surface inspection plate meets the highest performance and reliability requirements. The factory continuously invests in research and development to improve its products and manufacturing processes, staying at the forefront of innovation and technology in the industry.Additionally, the factory is dedicated to environmental sustainability and responsible production practices. It adheres to strict environmental regulations and standards, ensuring that its manufacturing processes have minimal impact on the environment. The factory also works towards minimizing waste and energy consumption, while maximizing the use of renewable resources and sustainable materials in its operations.In conclusion, Cast Iron Surface Inspection Plate Factory is a trusted provider of high-quality, durable and precise cast iron surface inspection plates for a wide range of industrial applications. With its commitment to quality, innovation, and customer satisfaction, the factory continues to be a leading supplier for businesses seeking reliable and cost-effective solutions for their precision measurement and inspection needs.

Top-quality Carbon Steel Wedge Gate Valves - Reliable Suppliers and Manufacturers on Hisupplier.com

Carbon Steel Wedge Gate Valve – The Ultimate Solution for Industrial NeedsThe industrial sector is vast and requires seamless operation with functionality and durability. Valves are crucial to industrial operations, and the quality of the valve determines the smooth functioning of industrial processes. Carbon steel wedge gate valves have become a go-to option for industries looking for durability, functionality, and long-term performance. What is a Carbon Steel Wedge Gate Valve? Carbon steel wedge gate valves are designed with a wedge-shaped gate that rotates to allow or restrict the flow of liquids or gases. The valve is made of carbon steel, which possesses high strength, durability, and resistance to wear and tear. The valve is aptly suited for high-pressure and high-temperature applications. Benefits of Carbon Steel Wedge Gate Valve 1. Durability: Carbon steel wedge gate valves offer high durability as they are made of carbon steel. Carbon steel is strong, robust and offers high resistance to wear and tear. 2. Corrosion Resistance: Carbon steel wedge gate valves are resistant to corrosion, making them an apt choice for industries dealing with liquids and gases. 3. High-Pressure Application: Carbon steel wedge gate valves are designed to withstand high pressure and are therefore frequently used in high-pressure applications. 4. Low Maintenance: Carbon steel wedge gate valves require minimal maintenance and offer long-term performance. 5. Cost-effective: Carbon steel wedge gate valves are cost-effective and offer high functionality for years. It is an all-in-one solution for industrial valve needs. Applications of Carbon Steel Wedge Gate Valve Carbon steel wedge gate valves are widely used in a range of industrial applications. Some of the applications are as follows- 1. Oil and gas exploration 2. Refineries and Petrochemical plants 3. Power generation plants 4. Chemical processing plants 5. Water treatment plants 6. Industrial boilers and furnaces 7. Pharmaceutical industry 8. Food and beverage processing 9. Municipalities Conclusion Carbon steel wedge gate valves are a robust and reliable solution for industrial valve needs. They offer high functionality, durability, and are cost-effective, making them an apt choice for a range of applications. Carbon steel wedges offer effective control over the flow of liquids and gases and therefore are frequently used in high-pressure and high-temperature applications. Industries seeking long-term performance must look towards carbon steel wedge gate valves for their valve needs.

High-Quality Measuring Tools for Precision Engineering

Cast Iron Measuring Tools Factory: Providing Precision in Measuring and GaugingIn the world of manufacturing, precision is an integral component that ensures high-quality products. Every detail counts, and even the slightest deviation can result in costly errors and unsatisfactory outcomes. For this reason, measuring and gauging tools are essential in ensuring accuracy and consistency in production processes.As a leading measuring and gauging tools supplier, our cast iron measuring tools factory provides top-of-the-line equipment that caters to various industrial needs. Our products are made with the highest quality materials and adhering to strict standards to guarantee precision, accuracy, and reliability.One of our flagship products is the cast iron measuring tool. Cast iron, known for its strength and durability, is an excellent material for measuring tools. It is immune to corrosion and wear and tear, making it ideal for demanding manufacturing conditions. At our factory, we use advanced techniques in casting and finishing to ensure that our cast iron measuring tools have the required tolerance levels and impeccable surface finish.Our cast iron measuring tools come in various forms, including squares, straight edges, surface plates, and angle plates. These tools are compatible with other measuring instruments such as micrometers, calipers, and height gauges, making them versatile options for measuring and testing.Another vital measuring and gauging tool in our collection is the granite parallel. Granite is renowned for its stability and hardness; hence, it is an excellent material for precision measuring. With our advanced grinding technology, we produce granite parallels with exceptional parallelism and excellent surface finish. Our granite parallels come in different sizes, from small to large, to cater to various industrial needs.The cast Iron vee shape block is another critical product in our measuring and gauging tool collection. It is a perfect tool for securely holding cylindrical objects in place during the measurement process. Our cast iron vee shape block features robust construction, exceptional surface finish, and precise tolerance levels that guarantee accuracy and reliability.Our granite angle plate is another vital tool for measuring and gauging. It is a versatile instrument that can be used for machining, measuring, and inspection. Our granite angle plate is made from high-quality granite, and it is precisely finished to ensure high accuracy and surface finish.Lastly, our granite measuring and control plate and granite master square are top-of-the-line products that cater to advanced measuring and gauging needs. These tools are ideal for precision measurement tasks, and they feature high accuracy and exceptional surface finish.In conclusion, at our cast iron measuring tools factory, we understand the importance of precision in manufacturing. We strive to provide quality measuring and gauging tools that guarantee accuracy and consistency in production processes. Our products are made with the highest quality materials and adhere to stringent standards to ensure reliability and longevity. Contact us today for all your measuring and gauging tool needs, and we will be glad to offer our expertise and quality products.

Quality Tools for Accurate Measurement in Granite Industry

Granite Tools For Measuring have long been a staple in the world of construction and architecture. These tools allow professionals to accurately measure and cut granite for a variety of applications, including kitchen countertops, floor tiles, and more. With their precision and durability, Granite Tools For Measuring have become an indispensable part of the industry.Today, we will take a closer look at the company {} and their contribution to the world of measuring tools. {Company} is a leading manufacturer of Granite Tools For Measuring, known for their high-quality products and innovative designs. With a focus on precision and reliability, {Company} has earned a reputation for excellence in the industry.One of the key features of Granite Tools For Measuring from {Company} is their advanced technology. These tools are equipped with cutting-edge measuring systems that allow for incredibly accurate and consistent results. This technology has revolutionized the way granite is measured and cut, making it easier than ever for professionals to achieve the perfect fit and finish.In addition to their advanced technology, {Company}'s Granite Tools For Measuring are also built to last. Made from high-quality materials such as stainless steel and aluminum, these tools are designed to withstand the rigors of the job site. This durability ensures that professionals can rely on their Granite Tools For Measuring for years to come, making them a sound investment for any business.Furthermore, {Company} offers a wide range of Granite Tools For Measuring to meet the diverse needs of their customers. From simple handheld measuring devices to advanced laser-guided systems, {Company} has a solution for every project. This versatility has made {Company} a trusted name in the industry, with professionals around the world turning to their products for their measuring needs.In addition to their innovative products, {Company} also provides exceptional customer service. Their team of experts is always on hand to provide support and guidance to professionals using their Granite Tools For Measuring. Whether it's technical assistance or product recommendations, {Company} is committed to helping their customers succeed.Looking ahead, {Company} is dedicated to continuous improvement and innovation. They are constantly researching and developing new technologies to further enhance their Granite Tools For Measuring. By staying at the forefront of the industry, {Company} is ensuring that their products will continue to meet the evolving needs of professionals in the construction and architecture fields.In conclusion, Granite Tools For Measuring from {Company} are a testament to the company's commitment to quality and innovation. With their advanced technology, durability, and versatility, these tools have become an essential part of the industry. Professionals can rely on {Company} for precision and reliability, knowing that their Granite Tools For Measuring will help them achieve outstanding results. With a dedication to customer service and a focus on continuous improvement, {Company} is a leader in the world of measuring tools, and their impact on the industry is sure to endure for years to come.

High-Quality Cast Iron Assembly Surface Plate Suppliers

Cast Iron Assembly Surface Plate Suppliers are in high demand for various industries such as automotive, aerospace, and machinery manufacturing. These surface plates are essential for providing a flat and stable surface for the assembly and inspection of precision parts and components. When it comes to finding a reliable and trusted supplier for these critical tools, one company that stands out is {}.{} is a leading provider of cast iron assembly surface plates, offering a wide range of sizes and specifications to meet the diverse needs of their customers. With a strong focus on quality and precision, {} has earned a solid reputation as a preferred supplier in the industry.The company's dedication to excellence is evident in their commitment to using high-quality materials and advanced manufacturing processes. This ensures that their surface plates are not only durable and reliable but also meet the strict accuracy and flatness requirements demanded by their customers. Additionally, {} has a team of skilled engineers and technicians who have the expertise to design custom solutions for specific applications, further enhancing the value they bring to their clients.One of the key factors that set {} apart from other suppliers is their ability to provide a comprehensive range of services to support their customers throughout the entire lifecycle of the product. From initial consultation and design to manufacturing, testing, and after-sales support, {} is fully equipped to meet the needs of their clients every step of the way. This level of service and support has been a major contributing factor to the company's continued success and growth in the industry.In addition to their commitment to quality and customer satisfaction, {} also places a strong emphasis on innovation and continuous improvement. They invest in research and development to stay at the forefront of technological advancements, allowing them to offer cutting-edge solutions that meet the evolving needs of their customers.As the demand for cast iron assembly surface plates continues to grow, {} is well-positioned to meet the increasing needs of the market. With their extensive experience, technical expertise, and unwavering commitment to excellence, they are poised to remain a top choice for companies in need of reliable and high-quality surface plates for their manufacturing and assembly processes.Furthermore, {} recognizes the importance of environmental sustainability and is dedicated to minimizing their impact on the environment. They adhere to strict environmental standards and employ eco-friendly practices in their manufacturing processes, ensuring that their products are not only top-quality but also environmentally responsible.With a strong track record of success and a clear dedication to meeting the needs of their customers, {} continues to be a trusted partner for companies in need of cast iron assembly surface plates. Their combination of quality, expertise, and customer-centric approach positions them as a top supplier in the industry, and their commitment to innovation and sustainability ensures that they will remain a leader in the field for years to come.In conclusion, the demand for cast iron assembly surface plates continues to increase, and {} has proven themselves as a reliable and trusted supplier in the industry. With their dedication to quality, customer satisfaction, innovation, and sustainability, {} is well-equipped to meet the evolving needs of their customers and maintain their position as a top choice for companies in need of high-quality surface plates.