High-Quality Machine Spare Parts for Granite Equipment

By:Admin

The company has a rich history dating back to its establishment in 1995. Since then, Granite Machine Spare Parts Company has continually evolved and expanded its product range to meet the changing needs of its customers. With a focus on quality and innovation, the company has earned a reputation for delivering reliable and cost-effective solutions to businesses in the granite processing industry.

The latest range of spare parts from Granite Machine Spare Parts Company is designed to enhance the performance and longevity of granite processing machinery. From cutting tools and blades to bearings and hydraulic components, the company offers a comprehensive selection of spare parts to suit a wide variety of machinery types and models. Each product is manufactured to the highest standards, using premium materials and cutting-edge technology to ensure optimal performance and durability.

In addition to their extensive product range, Granite Machine Spare Parts Company also takes pride in their exceptional customer service. The company's team of knowledgeable and experienced professionals is dedicated to providing prompt and personalized support to their customers. Whether it's technical advice, product recommendations, or assistance with orders, the team is committed to ensuring that every customer receives the assistance they need to keep their operations running smoothly.

Granite Machine Spare Parts Company also places a strong emphasis on accessibility and convenience for their customers. Through their user-friendly website and efficient logistics network, the company ensures that customers can easily browse their product range, place orders, and receive deliveries in a timely manner. This commitment to convenience reflects the company's dedication to delivering a seamless and hassle-free experience for their customers.

As the global demand for granite continues to rise, the importance of reliable and high-quality spare parts for granite processing machinery cannot be overstated. Granite Machine Spare Parts Company recognizes this need and is dedicated to supporting the industry with their comprehensive range of products and exceptional service. By staying at the forefront of innovation and maintaining a customer-centric approach, the company is well-positioned to continue meeting the evolving needs of businesses in the granite processing sector.

For businesses in the granite industry that are looking for a trusted partner for spare parts and support, Granite Machine Spare Parts Company offers a compelling combination of quality, reliability, and expertise. With a strong track record and a commitment to excellence, the company is poised to remain a leading supplier of spare parts for granite processing machinery for years to come.

Company News & Blog

High-Quality Measuring Tools for Precision Engineering

Cast Iron Measuring Tools Factory: Providing Precision in Measuring and GaugingIn the world of manufacturing, precision is an integral component that ensures high-quality products. Every detail counts, and even the slightest deviation can result in costly errors and unsatisfactory outcomes. For this reason, measuring and gauging tools are essential in ensuring accuracy and consistency in production processes.As a leading measuring and gauging tools supplier, our cast iron measuring tools factory provides top-of-the-line equipment that caters to various industrial needs. Our products are made with the highest quality materials and adhering to strict standards to guarantee precision, accuracy, and reliability.One of our flagship products is the cast iron measuring tool. Cast iron, known for its strength and durability, is an excellent material for measuring tools. It is immune to corrosion and wear and tear, making it ideal for demanding manufacturing conditions. At our factory, we use advanced techniques in casting and finishing to ensure that our cast iron measuring tools have the required tolerance levels and impeccable surface finish.Our cast iron measuring tools come in various forms, including squares, straight edges, surface plates, and angle plates. These tools are compatible with other measuring instruments such as micrometers, calipers, and height gauges, making them versatile options for measuring and testing.Another vital measuring and gauging tool in our collection is the granite parallel. Granite is renowned for its stability and hardness; hence, it is an excellent material for precision measuring. With our advanced grinding technology, we produce granite parallels with exceptional parallelism and excellent surface finish. Our granite parallels come in different sizes, from small to large, to cater to various industrial needs.The cast Iron vee shape block is another critical product in our measuring and gauging tool collection. It is a perfect tool for securely holding cylindrical objects in place during the measurement process. Our cast iron vee shape block features robust construction, exceptional surface finish, and precise tolerance levels that guarantee accuracy and reliability.Our granite angle plate is another vital tool for measuring and gauging. It is a versatile instrument that can be used for machining, measuring, and inspection. Our granite angle plate is made from high-quality granite, and it is precisely finished to ensure high accuracy and surface finish.Lastly, our granite measuring and control plate and granite master square are top-of-the-line products that cater to advanced measuring and gauging needs. These tools are ideal for precision measurement tasks, and they feature high accuracy and exceptional surface finish.In conclusion, at our cast iron measuring tools factory, we understand the importance of precision in manufacturing. We strive to provide quality measuring and gauging tools that guarantee accuracy and consistency in production processes. Our products are made with the highest quality materials and adhere to stringent standards to ensure reliability and longevity. Contact us today for all your measuring and gauging tool needs, and we will be glad to offer our expertise and quality products.

High-Quality Cast Iron Bed Plates for Manufacturing Applications

The renowned cast iron bed plates manufacturer has been making headlines lately with its innovative products and cutting-edge technology. With a rich history of over [XX] years in the industry, the company has established itself as a leader in the manufacturing of high-quality cast iron bed plates for various industrial applications.The company's journey began in [year] when it was founded by a team of passionate engineers and entrepreneurs. Since then, it has grown exponentially and has continuously expanded its product line to cater to the diverse needs of its customers. The company takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and technology to ensure precision and quality in every product.One of the key strengths of the company lies in its dedicated team of professionals who bring a wealth of experience and expertise to the table. From product design and development to manufacturing and quality control, the company's team works tirelessly to deliver top-notch cast iron bed plates that meet the highest standards of quality and performance.In addition to its commitment to quality, the company also places a strong emphasis on innovation. It continuously invests in research and development to stay ahead of the curve and bring new and improved products to the market. The company's constant drive for innovation has led to the development of advanced materials and designs that offer unparalleled performance and durability.Moreover, the company prides itself on its ability to customize its products to meet the specific requirements of its clients. Whether it's a unique design, size, or material specification, the company has the capability to tailor its products to suit the individual needs of its customers. This flexibility and customer-centric approach have earned the company a loyal and satisfied customer base across the globe.The company's cast iron bed plates find applications in a wide range of industries, including automotive, aerospace, energy, and heavy machinery. These bed plates are known for their superior flatness, dimensional stability, and resistance to wear and tear, making them the top choice for demanding applications where precision and reliability are paramount.In addition to its focus on product excellence, the company is also dedicated to sustainability and environmental responsibility. It has implemented various initiatives to reduce its environmental footprint, including the use of eco-friendly materials and energy-efficient manufacturing processes. By prioritizing sustainability, the company not only benefits the environment but also contributes to the long-term success and reputation of its brand.Looking ahead, the company has ambitious plans for the future. It aims to further expand its global presence and reach new markets, while continuing to push the boundaries of innovation and technology in the manufacturing of cast iron bed plates. With a strong foundation built on quality, innovation, and customer satisfaction, the company is well-positioned to achieve its goals and maintain its leadership position in the industry.In conclusion, the renowned cast iron bed plates manufacturer has established itself as a powerhouse in the industry, with its steadfast commitment to quality, innovation, and customer satisfaction. With a rich history, a talented team, and a focus on sustainability, the company is well-equipped to thrive in an ever-evolving market. As it continues to push the boundaries of manufacturing excellence, the company is set to shape the future of the industry and set new benchmarks for quality and innovation.

Ultimate Guide to Choosing the Perfect Granite Surface Plate for Small Jobs

Title: Precision Tools Company Introduces Innovative Small Granite Surface PlateIntroduction:Precision Tools Company, a leading manufacturer of high-quality industrial tools, is proud to announce the release of its latest innovation, a Small Granite Surface Plate designed to meet the evolving needs of various industries. This state-of-the-art surface plate offers unmatched precision, durability, and reliability, making it the go-to choice for professionals seeking superior workmanship.Unveiling Enhanced Features:The Small Granite Surface Plate showcases a host of enhanced features, ensuring optimal functionality and usability across diverse applications. Its compact size, balanced weight, and intuitive design enable seamless portability and ease of use in both workshop settings and on-site work environments. This allows professionals to maintain precision and accuracy across various projects.Engineered for Precision:Crafted from premium-grade granite, renowned for its strength and stability, the surface plate provides exceptional flatness and consistency. The high dimension stability of granite ensures minimal expansion or contraction due to changes in temperature or humidity, guaranteeing reliable results under any working conditions. This precision-engineered surface is suitable for rigorous measurement tasks, from industrial machining to quality control processes.Accurate Measurements:The Small Granite Surface Plate offers remarkable accuracy, allowing for precise measurement capabilities that adhere to industry standards. The finely-lapped surface provides an excellent base for the calibration of numerous tools and gauges, enabling professionals to check and verify measurements with ease. Whether it's for the alignment of machine components or the inspection of mechanical parts, this innovative surface plate promises reliable and consistent results.Versatile Applications:Precision Tools Company's Small Granite Surface Plate caters to a wide range of applications across industries such as manufacturing, engineering, automotive, aerospace, and more. From facilitating fine-tuning of intricate machine parts to assisting in the production of small precision components, this versatile tool serves as an indispensable asset for professionals seeking optimal precision and accuracy.Robust Durability:Built with longevity in mind, the Small Granite Surface Plate is designed to withstand the rigors of demanding industrial environments. Its robust construction ensures resistance against warping, corrosion, and wear, allowing for prolonged usage without compromising performance. Additionally, the surface plate's ability to absorb vibrations enhances stability during intricate measurement tasks, leading to accurate outcomes.User-Friendly Design:Precision Tools Company prioritizes user convenience with the Small Granite Surface Plate's ergonomic design. The compact size and lightweight nature of the surface plate make it easily transportable, enabling professionals to carry out measurements conveniently at various work locations. Furthermore, the surface plate's low-maintenance requirements save valuable time and effort, ensuring seamless integration into busy industrial workflows.A Commitment to Quality:With a strong commitment to quality, Precision Tools Company ensures each Small Granite Surface Plate undergoes rigorous testing and inspection to meet the highest industry standards. By integrating advanced manufacturing techniques and adhering to strict quality control procedures, the company guarantees that its products consistently exceed customer expectations.Conclusion:Precision Tools Company's introduction of the Small Granite Surface Plate demonstrates their dedication to providing innovative solutions that meet the evolving demands of industries worldwide. This state-of-the-art surface plate offers precision, durability, and reliability, while its user-friendly design and versatile applications make it a valuable asset for professionals across various sectors. As Precision Tools Company continues to push boundaries in precision tool manufacturing, they reaffirm their commitment to delivering top-quality tools that empower professionals to achieve unparalleled results.

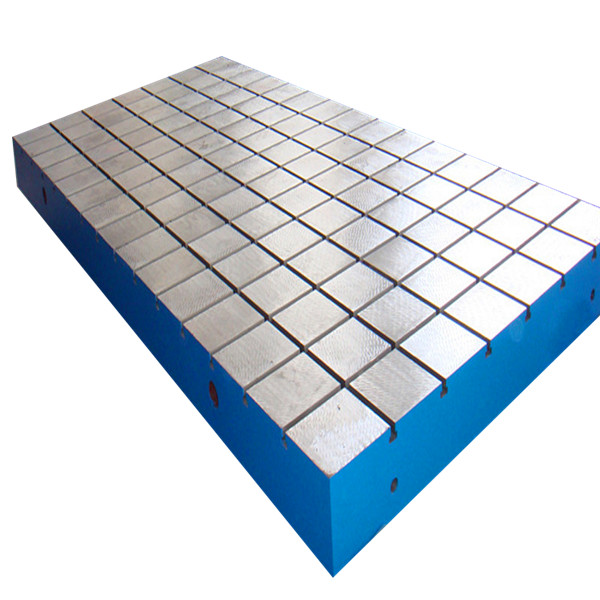

T-Slotted Floor Plates: Rigid Bases for Engineering Industries

When it comes to engineering industries, precision and accuracy are essential qualities for any production set up. One of the most important tools for achieving these qualities is the use of cast iron t-slotted floor plates. T-slotted floor plates are an essential part of any machining and assembly process, providing a solid foundation for various operations, including assembly, testing, inspection, and tooling. These plates are used for layout and marking, making them an invaluable tool for any engineering industry.A cast iron t-slotted floor plate is an ideal solution for any production set up, offering high accuracy, durability, and stability. The plates are manufactured using high-grade cast iron that offers superior strength and rigidity. The t-slotted design allows multiple clamps to be attached to the plate, making it easy to secure various fixtures and tooling. This feature enables engineers to work with large fixtures and special tooling without any distortion or misalignment, making it an ideal choice for production.One of the key benefits of t-slotted floor plates is their versatility. They can be used in a wide range of applications, from precision grinding, inspection, and fabrication to assembly work and large production set up. The plates offer an ideal working platform that is flat, reliable, and resist distortion, allowing engineers and production workers to work without interruptions.Assembly surface plates are essential tools for any production set up that requires high precision and accuracy. These plates offer a suitable surface for assembly operations, ensuring that components fit perfectly. They are designed to be flat, smooth, and rigid, preventing any warping or distortion that may affect the quality of the final product.Cast iron assembly surface plate suppliers offer a variety of plates for different applications. The plates are available in different sizes, designs, and materials, making it easy to choose one that suits the specific needs of your production setup. For instance, granite surface plates are ideal for applications that require higher accuracy, while cast iron plates are commonly used in general-purpose production.In conclusion, t-slotted floor plates and assembly surface plates are essential tools for any engineering industry. They offer a reliable, durable, and precise working surface, enabling engineers to work with large fixtures and tooling without any distortion or misalignment. Cast iron assembly surface plate suppliers offer a range of plates for different applications, making it easy to find one that suits your specific production needs. So, if you are looking for a reliable production set up, then a t-slotted floor plate or assembly surface plate is a worthwhile investment.

Affordable and Effective: Using Floor Tiles as Lapping Plates for Blade and Chisel Flattening

, Marble Tile Lapping Plate, Flattening Blades, Chisels, Soles of Planes, Affordable Solution, FineWoodworking.When it comes to woodworking, having sharp tools is essential. Dull blades, chisels or planes can make your woodworking experience frustrating and can leave you with subpar results. That's why it's important to invest in a good quality lapping plate to keep your tools sharp. However, buying a lapping plate can be expensive, which is why we'd like to suggest an affordable solution - using marble or granite tile as a high-quality lapping plate.Marble and granite tiles are readily available at any home decor or tile store for an affordable price. These tiles are extremely flat and have a smooth surface, providing the perfect platform for sharpening and flattening tools. Plus, they're durable and can withstand wear and tear for years of use. Here's how to use a marble or granite tile as a lapping plate:Step 1: Prepare your tileBefore using the tile as a lapping plate, make sure it's clean and dry. If there are any marks or scratches on the surface, use a fine-grit sandpaper to sand down the surface until it's smooth.Step 2: Add abrasiveApply a small amount of abrasive such as diamond paste or sandpaper. Use a low-grit abrasive to start with, and work your way up to higher grits as needed.Step 3: Start lappingGrab your blade, chisel or plane and start lapping. Hold your tool at a consistent angle and apply pressure as you move it back and forth across the plate. This will create an even, flat surface on your blade, chisel or plane.Step 4: Rinse and repeatContinue lapping until you've reached your desired level of sharpness. Rinse the tool and tile frequently to remove any excess abrasive and check your work often to ensure you're not removing too much metal from the tool.In conclusion, using marble or granite tile as a lapping plate can be a cost-effective and efficient way to keep your woodworking tools sharp and in good shape. It's an affordable alternative to expensive lapping plates and delivers the same results. With these simple steps, you can create a smooth and flat surface on your tools and produce excellent woodworking results. So, the next time you need to sharpen your tools, give this technique a try and experience the benefits.

Practical Guide to Scraping Cast Iron Surface Plates for Optimal Performance

In the world of manufacturing and engineering, precision is everything. When it comes to the accuracy of measuring and machining equipment, a high-quality surface plate is essential. However, over time, even the best surface plates will become worn and damaged, reducing their accuracy. That is where Scraping Cast Iron Surface Plate comes into play. Their specialized grinding and scraping techniques are used to restore even the most heavily damaged surface plates back to their original precision.Scraping Cast Iron Surface Plate, founded in 1993, is a professional manufacturing company that specializes in the production and maintenance of surface plates. They have been providing high-quality products and services to various industries, including the automotive, aerospace, and machine tool industries, for over two decades.Their team of highly skilled technicians uses advanced grinding and scraping techniques to repair and refurbish surface plates of all sizes. The processes they use are carefully designed to restore the original precision of the surface plate, making it as good as new. Additionally, they use only the highest-quality materials in their repairs, ensuring that the surface plate will continue to perform beautifully for many years to come.To ensure that their clients' needs are met, Scraping Cast Iron Surface Plate offers a wide range of services. They provide essential repairs, as well as complete refurbishments, to all types of surface plates. Their team can even design and produce custom surface plates tailored to specific needs. They can also perform on-site inspections, providing clients with a detailed analysis of the performance of their equipment.In recent years, Scraping Cast Iron Surface Plate has been recognized in the industry for their exceptional quality and service. Their commitment to excellence has earned them a loyal following of clients who rely on their expertise and precision in restoring surface plates.One of the company's recent projects involved restoring a surface plate used in a high-precision aerospace application. The plate had developed significant damage due to heavy use, and the client was concerned that a replacement would be needed. Scraping Cast Iron Surface Plate was called in to assess the damage and provide a solution. After carefully inspecting the plate, they determined that it could be repaired and set to work grinding and scraping the damaged areas. After a meticulous restoration process, the surface plate met the original accuracy specifications and was put back into service.Scraping Cast Iron Surface Plate's dedication to excellence and precision has earned them a reputation as one of the best surface plate repair and refurbishment companies in the industry. Their commitment to quality and unparalleled customer service makes them a trusted partner for companies looking to maintain the accuracy and efficiency of their equipment.In conclusion, when it comes to ensuring the precision and accuracy of surface plates, Scraping Cast Iron Surface Plate is the company to call. Their combination of state-of-the-art grinding and scraping techniques, as well as their commitment to using only the highest quality materials and providing exceptional customer service, makes them an industry leader in surface plate repair and refurbishment. Whether clients need a simple repair or a complete refurbishment, Scraping Cast Iron Surface Plate is the trusted partner that can get the job done right.

Revolutionizing Welding: The Latest Innovations in 3D Welding Tables

Title: Leading Welding Table Manufacturer Revolutionizes the Industry with 3D TechnologyIntroduction:Innovation in the welding industry has taken a significant leap forward as a renowned welding table manufacturer introduces cutting-edge 3D technology to their production process. This groundbreaking development ensures improved efficiency, accuracy, and convenience for welders worldwide.With their commitment to continuous improvement and groundbreaking solutions, the company aims to transform the welding experience and set a new standard in the industry. By leveraging 3D technology, they have revolutionized the manufacturing process, enhancing welding tables' quality while reducing production time and costs.3D Welding Table Manufacturer Redefines Quality and Precision:The integration of 3D technology into the manufacturing process allows the company to create welding tables with unparalleled precision and quality. Through the use of computer-aided design (CAD) software and advanced additive manufacturing techniques, they can develop intricate weld fixtures and complex geometries that were previously challenging to achieve.This newfound precision enables welders to improve their workmanship by providing optimal support and stability during the welding process. The 3D tables' superior flatness guarantees quality welds, as the surface ensures the components being worked on remain securely in position, minimizing distortion.Streamlining Work Processes:Not only does the incorporation of 3D technology enable the creation of high-quality welding tables, but it also streamlines work processes for welders. By implementing automated manufacturing processes, the company significantly reduces the time required to produce welding tables while increasing their production capacity.Moreover, the ability to customize welding tables based on welders' specific requirements adds a new level of versatility. Welders can now request tables with unique dimensions, fixture placement, or even integrated clamping systems, ensuring that their equipment perfectly suits their welding needs. This customization not only enhances the welding experience but also boosts overall productivity.Sustainable and Environmentally Friendly Initiatives:In addition to enhancing welders' efficiency and productivity, the 3D welding table manufacturer is also committed to sustainable and environmentally friendly initiatives. By adopting 3D printing technology, they reduce material waste during production considerably. This eco-conscious approach aligns with their vision of minimizing their carbon footprint and contributing positively to the environment.Furthermore, the company utilizes durable, high-quality materials in the production of their welding tables, ensuring longevity and reducing the need for frequent replacements. This sustainable manufacturing approach not only benefits the environment but also enhances welders' operational efficiency by providing robust and long-lasting equipment.Customer-Centric Approach:The company's commitment to customer satisfaction is reflected in their customer-centric approach. They understand that every welder has unique requirements and aims to provide individualized solutions, exceeding customer expectations.Through tailored customer support and after-sales services, they ensure that welders have access to continuous assistance throughout their welding journey. This aspect of their business sets them apart from competitors, as they prioritize creating lasting relationships with their customers.Future Prospects and Expansion:With the successful integration of 3D technology into their welding table manufacturing process, the company is poised for growth and expansion. Beyond gaining recognition within the welding industry, they foresee potential collaborations with other industry players interested in adopting their groundbreaking technology.Additionally, they plan to further enhance their product range by exploring advanced technologies such as artificial intelligence (AI) and Internet of Things (IoT) applications. These advancements will undoubtedly contribute to empowering welders and further improving their overall welding experience.Conclusion:As the welding industry continues to progress, the incorporation of 3D technology in the manufacturing process significantly impacts its future. This innovative welding table manufacturer has taken a bold step forward in revolutionizing the industry, transforming the way welders work. With their commitment to quality, precision, and sustainability, they have set a new standard for the industry, providing welders worldwide with efficient, reliable, and customized solutions.

High-Quality Granite Parts for Precision Needs Unveiled in Latest News

Title: Precision Manufacturing Bolstered with High-Quality Granite PartsSubtitle: Leading the Way in Precision Engineering Solutions[City, Date] - In an industry where precision manufacturing plays a critical role, the introduction of high-quality granite parts by an industry-leading company is set to revolutionize the precision engineering landscape. Renowned for its commitment to excellence, attention to detail, and cutting-edge innovation, the company aims to provide exceptional solutions to the ever-evolving demands of the manufacturing sector.Operating at the forefront of precision engineering technology, our company has long been recognized as a pioneer in providing state-of-the-art solutions for a wide range of industries. Through unparalleled expertise and a relentless pursuit of perfection, we have continuously pushed the boundaries of technological advancements, resulting in some of the finest precision parts in the market.Our latest breakthrough lies in the integration of precision granite parts, emphasizing the importance of material quality in the manufacturing process. Owing to the remarkable properties of granite, these parts are set to revolutionize the precision engineering industry, offering improved mechanical stability, enhanced durability, and unparalleled accuracy.By combining innovative design techniques with advanced fabrication methods, our engineers have successfully developed a range of granite parts that are seamlessly integrated into various precision manufacturing applications. Our cutting-edge production facilities, equipped with state-of-the-art CNC machinery, enable us to precisely shape and polish these granite parts, ensuring the utmost precision and accuracy.Granite, known for its exceptional hardness and dimensional stability, is a material that far surpasses traditional options such as aluminum and steel. Its natural resistance to temperature fluctuations and exceptional resistance to wear and tear make it an ideal choice for precision components that demand longevity and precision. Whether it's for semiconductor manufacturing, aerospace, medical equipment, or any other industry that requires precision engineering, our granite parts are set to raise the bar for performance and quality.One of the key features that sets our granite parts apart from the competition is our relentless commitment to quality control. Every step of the production process, from material selection to final inspection, adheres to stringent quality standards. This ensures that our customers receive only the highest caliber products that meet and exceed their expectations. Each part is meticulously inspected for precise dimensional accuracy, surface finish, and overall quality, ensuring that our granite parts seamlessly integrate into our client's manufacturing processes.Moreover, our company prides itself on providing tailored solutions to meet our clients' specific requirements. By offering customizable granite parts, we empower our customers to optimize their precision engineering processes. Whether it's tweaking dimensions, modifying surface finishes, or fine-tuning other specifications, our team of experts works closely with our clients to develop bespoke solutions that perfectly align with their unique manufacturing needs.The adoption of our precision granite parts is expected to make a significant impact across several industries. The improved accuracy, durability, and stability offered by these components will not only increase efficiency but also minimize downtime, reduce maintenance costs, and enhance overall productivity. As a result, companies utilizing precision manufacturing are set to experience substantial improvements in their operations and gain a competitive edge in their respective sectors.In conclusion, the introduction of high-quality granite parts by our company marks a significant milestone in the precision engineering industry. With our commitment to innovation, quality control, and customer satisfaction, we are confident that our precision granite parts will revolutionize precision manufacturing processes across multiple sectors. By harnessing the exceptional properties of granite, we have crafted components that defy existing standards and offer unrivaled performance in terms of accuracy, durability, and stability. As we continue to push the boundaries of precision engineering, our company will undoubtedly play a pivotal role in shaping the future of the manufacturing industry.

What Is Nodular Iron? Definition and Characteristics

Nodular Iron – A Strong and Durable MaterialNodular iron is a type of cast iron that has become increasingly popular in recent years due to its increased strength and durability. Also known as ductile iron, nodular iron is made by adding small amounts of magnesium to cast iron during the melting process, which leads to the formation of spherical graphite nodules within the iron matrix. This unique structure provides exceptional strength and resilience, making nodular iron an ideal material for a wide range of industrial applications.One of the key benefits of nodular iron is its superior mechanical properties. Compared to other types of cast iron, it has a much higher tensile strength, allowing it to withstand high loads and stress levels without breaking or deforming. This makes it particularly well-suited for applications where strength and resistance to wear and tear are essential, such as automotive parts, pipes, and machinery components.In addition to its mechanical properties, nodular iron is also highly resistant to corrosion, making it an excellent choice for outdoor applications where exposure to moisture and other environmental factors can lead to rust and degradation. Its high ductility and low shrinkage make it easy to work with, allowing it to be shaped and molded into a wide range of complex shapes and sizes.At (company name removed), we specialize in the production of high-quality nodular iron castings for a wide range of applications. Our state-of-the-art foundry facility is equipped with the latest technology and equipment, allowing us to produce castings of the highest quality and precision. Our team of experienced engineers and technicians work closely with our clients to develop custom solutions that meet their exact specifications and requirements, ensuring that each casting performs flawlessly under the most demanding conditions.Whether you need nodular iron castings for automotive, agricultural, or industrial applications, we have the expertise and resources to deliver the highest quality products on time and on budget. Our commitment to quality and customer satisfaction is second to none, and we pride ourselves on providing exceptional service and support to each and every one of our clients.In conclusion, nodular iron is a versatile and reliable material that continues to gain popularity across a wide range of industrial sectors. Its unique properties make it an ideal choice for applications where strength, durability, and resistance to wear and corrosion are essential, and its ability to be molded into complex shapes and sizes make it a go-to material for designers and engineers seeking robust and efficient solutions. At (company name removed), we are proud to be at the forefront of this dynamic and exciting industry, and we look forward to helping our clients achieve their goals with the latest advancements in nodular iron technology.