High-Quality Welding Table Manufacture for Your Workshop

By:Admin

The company's welding tables are designed to meet the needs of professionals and hobbyists alike, offering a sturdy and durable platform for various welding projects. Whether it's for metal fabrication, automotive repair, or DIY welding tasks, Welding Table Manufacture offers a range of products to suit different needs and applications.

In addition to welding tables, the company also provides a variety of welding accessories and equipment, including clamps, fixtures, and stands. With a commitment to delivering superior products, Welding Table Manufacture ensures that all of its products are made with high-quality materials and are built to last.

One of the key factors that sets Welding Table Manufacture apart from its competitors is its dedication to customer satisfaction. The company takes pride in offering personalized service and support to its customers, ensuring that they receive the products and assistance they need to complete their welding projects successfully.

Furthermore, the company understands the importance of continuous innovation and improvement. It invests in research and development to enhance its products and introduce new solutions to meet the evolving needs of the welding industry. By staying ahead of trends and technology, Welding Table Manufacture remains at the forefront of the market, offering cutting-edge products that deliver exceptional performance and reliability.

In addition to its commitment to quality and innovation, Welding Table Manufacture places a strong emphasis on environmental responsibility. The company adheres to strict standards and practices in its manufacturing processes to minimize its environmental impact. It strives to reduce waste, conserve energy, and use sustainable materials whenever possible.

Furthermore, the company is committed to giving back to the community. It supports various charitable initiatives and organizations, contributing to social and environmental causes to make a positive impact beyond its business operations.

With its strong focus on quality, innovation, customer service, and corporate responsibility, Welding Table Manufacture has earned a solid reputation in the industry. Its products are trusted by professionals and enthusiasts alike, and its dedication to excellence has earned the loyalty of a wide customer base.

Looking ahead, Welding Table Manufacture aims to continue its growth and expansion, both in terms of its product offerings and its market reach. The company remains committed to delivering outstanding products and services, and it looks forward to further strengthening its position as a leading provider of welding solutions.

As the welding industry continues to evolve, Welding Table Manufacture is poised to adapt and thrive, remaining a go-to source for welding tables and accessories. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to continue its success and uphold its reputation as a top-tier supplier in the field of welding solutions.

Company News & Blog

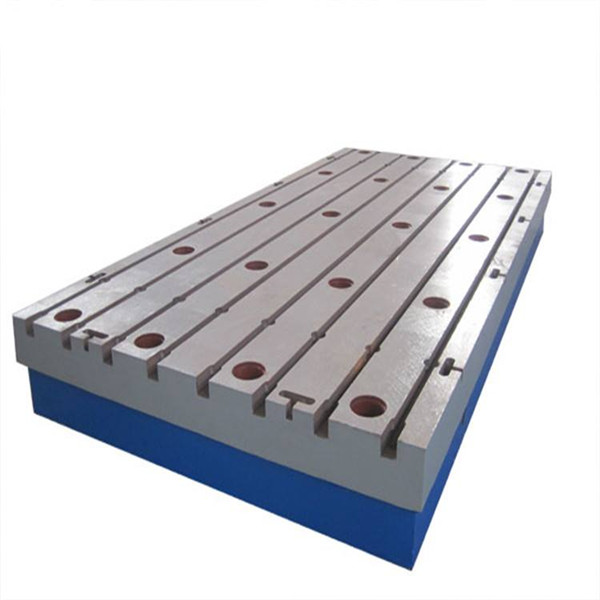

Durable Cast Iron Floor Bed Plate for Industrial Use

Cast Iron Floor Bed Plate: A Reliable Solution for Industrial MachineryIn the world of heavy duty machinery, stability and precision are key factors for success. That's why companies rely on robust and dependable tools such as the Cast Iron Floor Bed Plate, manufactured by a leading provider in the industry.The Cast Iron Floor Bed Plate is an essential piece of equipment for a wide range of industrial applications. Its solid construction and exceptional stability make it an ideal foundation for the installation and operation of heavy machinery. From CNC machines to heavy duty presses, this bed plate provides a reliable and sturdy platform for precision manufacturing.The company behind this innovative product is a renowned manufacturer with a long-standing reputation for excellence in the industry. With a history dating back to [insert year], they have earned the trust of their customers through their commitment to quality and innovation. Their extensive experience and expertise in the field of heavy-duty machinery make them a trusted partner for businesses around the world.The Cast Iron Floor Bed Plate is designed to meet the rigorous demands of industrial settings. Constructed from high-quality cast iron, it offers exceptional stability and rigidity, ensuring that machinery operates with precision and accuracy. The bed plate is available in a range of sizes and configurations to accommodate various industrial applications, making it a versatile solution for a wide range of needs.One of the key features of the Cast Iron Floor Bed Plate is its superior flatness and surface finish. This ensures that machinery can be installed and operated with the utmost precision, delivering high-quality results with every use. The bed plate's durable construction also makes it resistant to wear and tear, providing long-term reliability and performance.In addition to its outstanding performance, the Cast Iron Floor Bed Plate is designed with ease of use and maintenance in mind. Its robust construction requires minimal upkeep, saving businesses time and resources in the long run. This, combined with its exceptional longevity, makes it a cost-effective investment for businesses looking to improve their manufacturing capabilities.Furthermore, the company's commitment to customer satisfaction is evident in their dedication to providing exceptional service and support. From initial consultation to after-sales assistance, their team of experts is on hand to offer guidance and expertise every step of the way. This level of support allows businesses to maximize the benefits of the Cast Iron Floor Bed Plate, ensuring that their machinery operates at peak performance.In conclusion, the Cast Iron Floor Bed Plate is a reliable and versatile solution for businesses in need of a stable foundation for their heavy-duty machinery. With its solid construction, exceptional precision, and long-term durability, it is a valuable asset for any industrial operation. Partnering with a trusted manufacturer like [company name] ensures that businesses can access the highest quality products and support, setting them up for success in the competitive world of manufacturing.

Durable and Heavy-Duty Cast Iron Base Plate for Industrial Use

article.Cast Iron Base Plate: The Ideal Choice for Your Construction and Industrial NeedsEvery construction project and industrial machining task requires a strong and sturdy foundation. This is where cast iron base plates come into play. A cast iron base plate is a flat, rectangular metal plate used to provide a stable and level surface for heavy machinery and structures to rest on.One company that stands out in the production and supply of cast iron base plates is {remove brand name}. {The company} is known for their premium-quality cast iron base plates that are second to none in the industry. With their commitment to providing the best solutions for construction and industrial needs, {the company} has earned a reputation as a reliable distributor of high-grade cast iron base plates.What Makes {The Company}'s Cast Iron Base Plate Stand Out?{The company}'s cast iron base plate is made from high-quality materials that guarantee strength, durability, and longevity. The base plate is a solid piece of metal that is highly resistant to bending and warping, making it the perfect choice for heavy-duty applications. It is designed to withstand the weight of machinery and structures, ensuring stability and precision.Furthermore, {the company}'s cast iron base plates undergo a meticulous casting process that ensures uniformity in the metal's composition and structure. This results in a surface that is free from rough spots, bumps, or depressions. The base plate's even surface provides greater accuracy in machining, resulting in better production output and efficiency.In addition, {the company}'s cast iron base plate is easy to install, making it possible to move the heavy-duty machinery to your desired location. This provides flexibility and convenience, especially if you have limited space in your facility. The base plate's stability also helps to prevent accidents and incidents that may arise from using unreliable or unsteady platforms.Why Choose {The Company} for Your Cast Iron Base Plate Needs?{The company} understands the importance of reliability and durability in construction and industrial applications. Therefore, they make it their priority to provide premium-quality cast iron base plates that meet their customers' needs. They offer a wide range of cast iron base plates that cater to different applications, from small-scale machining to heavy-duty construction.Besides their quality products, {the company} also provides excellent customer service. Their team of experts is always ready to assist customers with any inquiries and concerns regarding their products. They also offer advice and recommendations on the appropriate type and size of cast iron base plate for specific applications.Moreover, {the company} offers competitive pricing for their top-grade cast iron base plates, making it affordable for customers to purchase them without compromising quality. They also have a comprehensive warranty and after-sales service to ensure customer satisfaction.ConclusionA cast iron base plate is an essential component in construction and industrial applications. It provides a stable and level surface that supports heavy-duty machinery and structures. {The Company} provides top-grade cast iron base plates that are durable, reliable, and long-lasting. Their commitment to quality and customer satisfaction make them a trusted name in the industry. With {the company}'s cast iron base plates, you can be assured of precision, accuracy, and stability in your projects.

Top 3D Worktable Made of Cast Iron Revealed in Latest News

Industrial advancements have made it possible for businesses to increase the efficiency of their operations and attain higher levels of productivity. For manufacturers, having the right tools and equipment in the production process can make a significant difference in their output. With this in mind, one company has introduced a game-changing product that promises to revolutionize the manufacturing industry.The cast iron 3D worktable, from a reputable company specialized in machine tool accessories and metalworking, is a new essential tool in manufacturing. Designed to withstand heavy loads and provide excellent precision, the table is an ideal platform for a range of operations, including milling, drilling, and grinding. With this new product, industrial operations will be able to achieve better levels of accuracy, reliability, and stability in their processes.The cast iron 3D worktable has been engineered with cast iron material that is famous for its durability and stability, making it suitable for heavy-duty applications. With perfectly milled surfaces, the table ensures that workpieces remain in place and can withstand vibrations and pressure, while at the same time providing the user with a level of precision that is unmatched by other conventional worktables.The table's flat and smooth surface allows for smooth travel of workpieces while maintaining accuracy and precision. Additionally, the table comes with T-slots that offer a perfect fit for clamping and securing workpieces in place, increasing the table's versatility while minimizing safety risks in the workplace. This feature makes the table ideal for a variety of industrial uses, including but not limited to metalworking, manufacturing of machinery and equipment, and construction.The manufacturer has employed modern technology to develop the cast iron 3D worktable, incorporating Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) in the design and manufacturing processes. The result is a product that provides unrivaled accuracy and dependability, making it ideal for use in precision applications.The company behind the cast iron 3D worktable is a well-respected leader in the machine tool accessories and metalworking industry. With a history of providing top-notch technology to various industries worldwide, the manufacturer has established a reputation for quality, reliability, and exceptional customer service. The addition of this product to their line-up follows their tradition of offering superior equipment and accessories that meet the changing needs of their customers.According to the product manager, "The cast iron 3D worktable is designed to deliver unmatched performance and stability while providing our customers with the flexibility they need in their operations. Our engineers have taken into consideration the demands of industrial workspaces, and we are confident that the table will make a significant contribution to modernizing the manufacturing industry."The cast iron 3D worktable comes in various sizes, providing versatility for multiple operations. This new product is an investment that will pay for itself, as its durability and longevity ensure it will last for generations to come. This essential tool will bring reliability, stability, and precision to various industrial operations and can be the difference between a successful or unsuccessful project.In conclusion, with the introduction of the cast iron 3D worktable, the manufacturing industry will experience enhanced stability, accuracy, and productivity. The utilization of cast iron material, coupled with modern technology, has resulted in a product that delivers optimal performance. This new addition to the company's range of machine tool accessories is evident of their commitment to excellence and meeting the changing needs of their customers. With this new product, the manufacturing industry is one step closer to modernization.

Revive Your Blades with a Super Flat Granite Surface Plate

Granite Surface Plate Helps Restore Blades to PerfectionIf you're a woodworker or metal worker, you know how important it is to have a sharp blade. A dull blade not only makes it difficult to get a clean cut, but it can also be dangerous. That's why many professionals turn to a granite surface plate to restore their blades.The granite surface plate, also known as a surface table or precision granite plate, is a flat stone slab made of granite. This natural stone is prized for its hardness, durability, and resistance to wear and tear. Granite surface plates are often used in manufacturing, machining, and metrology to provide a flat surface for measuring and testing. But they are also becoming more popular among hobbyists and DIY enthusiasts for sharpening blades.One company that offers granite surface plates for blade restoration is Cool Tools. Based in Santa Fe, New Mexico, Cool Tools has been supplying craftsmen, metalworkers, and jewelry makers with high-quality tools and equipment since 1995. They offer a range of granite surface plates in different sizes and thicknesses, as well as other accessories to help with blade restoration.To use a granite surface plate for blade restoration, you'll need a piece of sandpaper or a sharpening stone and some honing oil. Simply lay the surface plate flat on a table or workbench, then place your blade on the plate at the desired angle. Start with a coarse grit sandpaper or stone to remove any nicks or chips in the blade, then move on to a finer grit to polish the edge. Apply honing oil to the surface plate to lubricate the blade and prevent it from overheating.One of the benefits of using a granite surface plate for blade restoration is its flatness. The surface plate is guaranteed to be flat within a certain tolerance, usually measured in microns. This means that the surface is perfectly level and straight, allowing you to sharpen your blade evenly and accurately. Some surface plates even come with calibration certificates that verify their precision.Another advantage of using a granite surface plate for blade restoration is its durability. Unlike other materials such as glass or metal, granite is less likely to warp or bend over time. This means that your surface plate will last for years, even with heavy use. Granite is also less likely to scratch or chip, which can damage your blade or cause it to become dull more quickly.In addition, granite surface plates are easy to clean and maintain. Simply wipe them down with a damp cloth after use to remove any debris or oil. You can also use a mild detergent if necessary. Avoid using harsh chemicals or abrasive cleaners, as these can scratch the surface and dull your blade.If you're interested in using a granite surface plate for blade restoration, consider purchasing one from Cool Tools. They offer a range of sizes and thicknesses to suit your needs, as well as other accessories such as honing oil and rubber feet to keep your surface plate stable during use. Cool Tools also offers excellent customer service and fast shipping, so you can start restoring your blades to perfection in no time.

DIY Granite Surface Plate: How to Make One with 3 Plates

When it comes to precision machining and measurement, having a reliable surface plate is crucial. While there are various types of surface plates available in the market, granite surface plates are one of the most widely used. However, buying such a plate can be expensive. Hence, some people opt to make their own using the 3 plates method. In this blog, we will discuss what materials are required to make a granite surface plate and the process involved.Materials RequiredBefore we delve into the process, it's essential to have all the necessary materials in place. Here's a list of things you'll need:- 3 surface plates- Epoxy- Two-part epoxy hardener- Sandpaper- LevelThe first step is to purchase three granite surface plates. It's vital that you buy high-quality plates that are flat and have a smooth surface. You don't need brand names when buying these plates; you can get generic ones at a lower price.ProcessOnce you have all the required materials, you can start the process of making your surface plate. Here are the steps involved:1. Clean the surface platesBefore bonding the plates together, ensure that they are clean. You can use a damp cloth to wipe away any dirt and dust particles.2. Level the surface platesUse a level to ensure that all the surface plates are horizontal. If one or two of the plates are not level, it will affect the overall accuracy of the surface plate.3. Prepare the epoxyFollow the instructions on the epoxy packaging and mix the two-part epoxy hardener thoroughly.4. Apply the epoxyApply a 1/8 inch of epoxy evenly on each surface. Be sure to apply it in a thin layer and avoid any air bubbles.5. Put the plates togetherCarefully place the three surface plates on top of each other. Ensure that the plates align correctly.6. Leave it to cureLet the epoxy cure according to the manufacturer's instructions. It usually takes about 24 to 48 hours to cure fully.7. Finish the surface plateOnce the epoxy has cured, use sandpaper to smoothen any rough spots or bumps on the surface. Be gentle when using the sandpaper, so you do not risk damaging the surface plate.8. Test the surface plateBefore using your newly made surface plate, verify its accuracy using a dial indicator. If it's not accurate, you may need to repeat the process.Advantages of Making Your Surface PlateMaking your surface plate is a cost-effective alternative to buying one. It's ideal for individuals who require a surface plate for occasional use but can't afford to invest in an expensive one. Making your surface plate also gives you the flexibility to customize it according to your needs.ConclusionIn conclusion, making a granite surface plate using the 3 plates method is achievable. With the right materials and patience, you can create a flat, accurate, and reliable surface plate. As a bonus, you get the satisfaction of knowing that you made something useful with your own hands.

Discover the Benefits of Cast Iron in MAGMAinteract for Your Next Cooking Adventure" could be rewritten to "Explore the Advantages of Cast Iron for Your Next Culinary Experience.

Cast Iron V Blocks: Strength and Reliability for Precision MachiningWhen it comes to precision machining, the tools and fixtures used are just as important as the machines themselves. One of the most critical fixtures in machining is V blocks. These special blocks are designed to hold and support round or cylindrical parts during machining.Of all the materials available for making V blocks, cast iron is one of the most popular choices. In this blog, we'll explore the benefits of cast iron V blocks and why they are the ideal choice for precision machining.1. Strength and DurabilityCast iron is a strong and durable material that can withstand the rigors of heavy-duty machining. It is resistant to wear and tear and can handle high-temperature environments without warping or cracking.This makes cast iron V blocks ideal for long-term use and ensures that they will maintain their precision over time. The strength and durability of cast iron also mean that it can withstand the force of high-speed cutting without breaking or distorting.2. Excellent Vibration Damping PropertiesOne of the biggest challenges in precision machining is controlling vibration. Vibrations can negatively affect the part being machined, leading to poor surface finish and alignment issues.Cast iron has excellent vibration damping properties, which means that it can absorb vibrations and prevent them from affecting the machined part. This is crucial for achieving high-precision and high-quality parts.3. Dimensional StabilityCast iron has a high degree of dimensional stability, which means that it maintains its shape and size under varying temperature and humidity conditions. This makes it an ideal material for precision machining fixtures like V blocks, which need to maintain their accuracy across a range of working conditions.Cast iron V blocks are also resistant to expansion and contraction due to temperature changes, which ensures that they maintain their precise alignment with the machined surface.4. Low Coefficient of Thermal ExpansionCast iron has a low coefficient of thermal expansion, meaning that it expands and contracts relatively little as temperatures change. This makes it an ideal material for machining fixtures that need to maintain their precise dimensions across a range of operating temperatures.Cast iron V blocks are particularly useful in high-temperature machining applications. They can withstand the high temperature of cutting tools and prevent any expansion or distortion that could affect the accuracy of the machined parts.5. VersatilityCast iron is a versatile material that can be easily machined to produce a wide range of shapes and sizes. This makes it an ideal material for V blocks, which come in various sizes, from small blocks used for precision measurement to large blocks designed for holding heavy cylindrical parts.ConclusionIn conclusion, cast iron V blocks are an excellent choice for precision machining. Their strength, durability, vibration damping properties, dimensional stability, and low coefficient of thermal expansion make them ideal for high-precision machining applications.If you're looking for high-quality cast iron V blocks for your machining needs, look no further than MAGMAinteract. Our cast iron V blocks are made from the highest quality materials and are designed to provide the strength, reliability, and precision you need for the most demanding machining applications.

Discover the Latest Innovation in Welding Tables for Efficient and Precise 3D Welding

Modular 3D Welding Tables Revolutionize the Welding IndustryIn recent years, the welding industry has experienced significant advancements in technology and techniques, greatly improving the efficiency and accuracy of the welding process. One such innovation making waves in the industry is the introduction of modular 3D welding tables. With their unrivaled versatility and precision, these tables have revolutionized the way welders approach their work, offering countless benefits to companies and individuals in the welding field.Developed by a pioneering company at the forefront of welding technology, these modular 3D welding tables have quickly become an indispensable tool for welders worldwide. By combining the company's extensive knowledge of welding with advanced engineering techniques, they have created a product that addresses various challenges faced by welders daily.One of the key features of these modular 3D welding tables is their adaptability to a wide range of welding projects. Traditional welding tables often have fixed dimensions, limiting the types of projects that can be worked on. In contrast, the modular 3D welding tables can be easily customized and configured to meet specific project requirements. This flexibility enables welders to work on projects of different sizes and shapes, ensuring precise and efficient welding regardless of the complexity of the task.The modular design of these welding tables allows for effortless assembly and disassembly, saving valuable time and effort for welders. In addition, the tables are constructed from high-quality materials that are resistant to heat and deformation, ensuring their durability and longevity. Welders can rely on these tables to withstand the demands of their work, employing them for countless projects without fear of premature wear or damage.Moreover, these innovative welding tables are equipped with a highly accurate 3D measuring system, enabling welders to achieve precise alignment and positioning of their workpieces. This feature eliminates the need for additional tools, such as traditional measuring equipment, saving both time and expenses. The tables also incorporate intelligent software that assists in optimizing welding parameters, enhancing workflow efficiency and ensuring consistent quality in the welds.Furthermore, the company behind these tables provides comprehensive training and support for their customers. Recognizing that adapting to new technology can be challenging, especially for seasoned welders accustomed to traditional methods, they offer hands-on training sessions and technical assistance to help users make the most of the tables' capabilities. This commitment to customer success sets them apart from competitors in the industry and establishes a strong relationship between the company and its customers.The impact of these modular 3D welding tables on the welding industry is substantial. Welders can now tackle a wider range of projects with improved efficiency, accuracy, and overall quality. As a result, companies employing these tables have reported increased productivity and reduced costs. The tables' versatility has also paved the way for innovations in welding techniques, inspiring welders to push the boundaries of what can be accomplished.In conclusion, the introduction of modular 3D welding tables has changed the game for welders worldwide. Through their adaptability, precision, durability, and user-friendly features, these tables have revolutionized the welding process. By embracing this innovative technology, companies and individuals in the welding industry can elevate their work to new heights, achieve greater success, and ultimately shape the future of welding.

Maintaining Precision of Used Cast Iron Surface Plates with Routine Restoration

Keeping Precision Restoration for Your Used Cast Iron Surface PlateCast iron precision surface plates are essential tools widely used in the manufacturing industry. Their importance lies in their ability to provide accurate and level surfaces to measure and inspect various mechanical parts. However, with prolonged use, these plates can experience wear and tear, leading to a decrease in surface precision.Half Yearly InspectionOne way to keep your cast iron surface plate in top-notch condition is by performing regular inspections. After using the plate for half a year, it's essential to inspect the plate's surface precision to ensure it aligns with industry standards. You can use various measuring instruments such as micrometers, dial gauges, and straight edges to assess the surface's flatness, parallelism, and roughness.If your inspection reveals that the precision is not up to standard, you should consider repairing the plate rather than continuing to use it in its current condition. Minimum surface specifications dictate that the surface should be within 2-5 microns in flatness and no more than 0.03 mm in parallelism. Failure to maintain the recommended measurements may result in inaccurate readings, leading to faulty production and delayed projects.Restoration TechniquesVarious techniques can be used to restore your cast iron precision surface plate's surface. One common method is to scrape the surface to remove any high spots on the surface, which could lead to inaccuracy. Skilled technicians use scraping tools to level the plate uniformly, achieving the required flatness levels. The technicians then repeat the surface inspection to ensure that the plate meets the required standards.Another restoration technique involves the use of a milling machine, which grinds down any high spots on the surface. This method is effective when used on larger plates that cannot be scraped because it is time and labor-intensive. Other restoration techniques that can be used include lapping, planing, and the use of abrasives.Preventive MeasuresWhile restoration techniques can give your cast iron precision surface plate a new lease of life, it's essential to implement preventive steps to avoid the wear and tear that necessitates the restoration in the first place. Some of the measures you can take include:- Proper Care and Maintenance: A simple yet effective solution to prolonging the life of your cast iron surface plate is proper care and maintenance. This includes cleaning the surface regularly, using protective covers, avoiding dropping heavy objects on the plate, and storing the plate in a dry environment.- Re-Calibration: Regular re-calibration of the surface plate using one or more dependable master lengths and inspection instruments will help identify when the surface plate requires professional calibration.- Avoid Corrosion: Cast iron surface plates are susceptible to rust and corrosion, which can cause surface irregularities. You can avoid this by applying a protective coating to the surface to prevent moisture buildup. Waxing is one more way to avoid this!In ConclusionProper maintenance practices and regular inspection of your cast iron precision surface plate will not only prolong its life span but also improve the accuracy of the measurements taken on it. It is important to note that restoring the plate's surface should only be carried out by a skilled technician as the process requires accuracy and precision. Always ensure that your cast iron surface plate is in top condition before using it to avoid faulty production and unnecessary delays in your projects.

Calibrating Granite Surface Plates Outside of Workplace: A Feasibility Study Has your granite surface plate been calibrated outside of your Q.C lab? Find out if this is a viable option and learn tips for safe transportation.

Granite Reference Plate Calibration and Transportation to QC LabGranite reference plates are used in various industries for precision measurement of equipment or parts. These plates are made from high-quality granite and calibrated to ensure accurate measurements. However, over time, the granite surface may become worn or damaged, which requires recalibration to maintain accuracy.In some cases, calibration of a granite reference plate may be done outside the workplace laboratory. This involves sending the granite plate to a calibration center where it is inspected and recalibrated. However, the granite plate needs to be transported back to the Q.C. lab once the calibration is complete.Transporting a granite reference plate requires careful attention to prevent any damage or changes that might affect its calibration and accuracy. Here are some tips to ensure safe transportation of a granite reference plate:1. Secure Packaging: The granite reference plate should be properly packed to avoid any damages during transportation. Use bubble wrap, foam padding or any other appropriate packaging materials to protect the plate from scratches or breakage.2. Temperature control: Granite reference plates are sensitive to temperature changes. They should be kept in a controlled temperature environment to avoid any thermal expansion or contraction during transportation.3. Specialist transport: Use specialist transport companies or courier services that have experience in handling and transporting granite reference plates.4. Insurance: It is important to insure the granite reference plate during transportation to protect against any damages or loss. This will help cover the cost of repair or replacement should any damage occur.Once the granite reference plate is transported to the Q.C lab, it should be carefully inspected to ensure that it has not suffered any damage during transportation. The plate should also be recalibrated to re-establish its accuracy.In conclusion, recalibrating a granite reference plate outside the workplace laboratory and the subsequent transportation of the plate to the lab requires careful handling. Taking care to follow these tips will help maintain the plate’s calibration and accuracy, thus ensuring accurate measurements of equipment or parts.

Expert Tips to Finding Quality Grey Cast Iron Castings for Your Project" -> "Expert Tips to Finding Quality Grey Iron Castings for Your Project

Title: Leading Manufacturer Introduces High-Quality Grey Cast Iron CastingsIntroduction (70 words):In today's manufacturing industry, grey cast iron is a highly sought-after material owing to its exceptional properties such as high strength, wear resistance, and excellent thermal conductivity. Leading the way in providing superior cast products, our company (brand name omitted) is thrilled to announce the introduction of its new line of high-quality grey cast iron castings. With precision engineering, advanced manufacturing techniques, and a commitment to customer satisfaction, our company is poised to dominate the market and meet the growing demand for cast iron products.Paragraph 1 (100 words):Our company has a rich history that spans over three decades, marking our solid presence as a premier manufacturer of cast iron castings. With a state-of-the-art facility and a team of highly skilled engineers and technicians, we have consistently delivered reliable and superior cast iron products across various industries. Our expertise lies in developing grey cast iron castings that excel in both mechanical and metallurgical properties. This expertise, combined with our commitment to innovation and continuous improvement, has earned us the trust and loyalty of our customers.Paragraph 2 (100 words):Our grey cast iron castings are meticulously designed to meet the diverse needs and specifications of our clients. We pride ourselves on utilizing the highest quality raw materials, employing cutting-edge technologies, and adhering to stringent quality control processes. This ensures that our castings exhibit exceptional strength, durability, and dimensional accuracy. Furthermore, our castings benefit from excellent machinability and superior anti-corrosion properties. Whether it is for heavy machinery, automotive parts, or other industrial applications, our grey cast iron castings guarantee unmatched performance and dependability in the most demanding environments.Paragraph 3 (120 words):At our state-of-the-art manufacturing facility, we leverage advanced casting methods such as green sand casting, shell molding, and investment casting. These techniques ensure that our grey cast iron castings are not only of the highest quality but also boast intricate designs and tight tolerances. Moreover, our dedicated research and development team continually explores innovative ways to enhance the properties of our castings while adhering to industry standards. This commitment to innovation positions us as a market leader capable of meeting the ever-growing demands and quality expectations of our esteemed clients worldwide.Paragraph 4 (120 words):As an environmentally conscious organization, we emphasize sustainable manufacturing practices. Our grey cast iron castings are made from recycled materials, reducing waste and minimizing environmental impact. Additionally, our efficient production processes not only optimize energy usage but also significantly reduce air emissions and water consumption. By incorporating sustainable practices into our manufacturing operations, we are not only contributing toward a greener future but also ensuring that our customers receive ethically produced castings.Conclusion (90 words):In conclusion, our company (brand name omitted) is excited to introduce our new line of high-quality grey cast iron castings. With our decades of expertise, cutting-edge technology, and dedication to customer satisfaction, we are confident that our offerings will fulfill the needs of various industries. As a market leader, we remain committed to delivering superior castings that boast exceptional mechanical properties, dimensional accuracy, and long-lasting performance. With an unwavering focus on innovation and sustainability, we aim to maintain our position at the forefront of the industry while providing our customers with reliable and durable cast iron solutions.