Top 5 Large Welding Tables for Your Workshop

By:Admin

[City, Date] – [Company Name], a leading manufacturer of industrial equipment, is excited to introduce its latest product, the Large Welding Table. This innovative piece of equipment is designed to provide a reliable and durable work surface for welding professionals in a variety of industries.

The Large Welding Table from [Company Name] is constructed with heavy-duty materials and is built to withstand the demands of daily use in a busy welding shop. With a spacious working area and a sturdy frame, this table provides a stable and secure platform for welding projects of all sizes.

One of the key features of the Large Welding Table is its adjustable height, which allows users to customize the table to their preferred working height. This feature enhances user comfort and reduces the risk of strain or fatigue during long welding sessions. Additionally, the table is equipped with built-in clamps and vices to secure workpieces in place, ensuring precise and accurate welding results.

The Large Welding Table is ideal for a wide range of welding applications, including MIG, TIG, and stick welding. Its versatility and durability make it an essential piece of equipment for professional welders in industries such as automotive, aerospace, construction, and manufacturing.

In addition to its practical design, the Large Welding Table is also compatible with a range of accessories, such as shelves, drawers, and tool holders, to further customize and optimize the work surface. This adaptability makes the table a valuable investment for any welding operation, large or small.

“At [Company Name], we are dedicated to providing high-quality, reliable equipment for professionals in the industrial sector,” said [Spokesperson Name], [Job Title] at [Company Name]. “The Large Welding Table is the latest example of our commitment to meeting the needs of our customers and delivering innovative solutions for their work environments.”

As a company with a long history of manufacturing excellence, [Company Name] has a reputation for producing top-of-the-line industrial equipment that meets the rigorous demands of modern industrial applications. The Large Welding Table is the latest addition to its extensive product lineup, which includes welding machines, cutting equipment, and other essential tools for metalworking and fabrication.

Customers can expect the same level of craftsmanship and attention to detail that [Company Name] is known for in the design and production of the Large Welding Table. Backed by a team of experienced engineers and quality control specialists, this product is built to meet the highest standards of performance and reliability.

The Large Welding Table is now available for purchase through [Company Name]’s network of authorized distributors and dealers. For more information about this product and other industrial equipment from [Company Name], visit [website] or contact [email address] for sales inquiries.

About [Company Name]:

[Company Name] is a leading manufacturer of industrial equipment, specializing in welding machines, cutting tools, and metalworking accessories. With a focus on quality, performance, and innovation, [Company Name] has established itself as a trusted partner for professionals in a wide range of industries. The company is committed to delivering reliable solutions that meet the evolving needs of its customers and supporting them with expert technical assistance and customer service.

For media inquiries, please contact:

[Media Contact Name]

[Media Contact Title]

[Company Name]

[Phone Number]

[Email Address]

-END-

Company News & Blog

and Foundation Repair.Underpinning is an essential part of foundation repair. It is a process that involves strengthening a foundation that has been weakened by factors such as soil settlement, water infiltration, and structural damage. The process is done by adding support to the foundation, making it more stable and secure.The use of underpinning wedges is a common method used in underpinning. The wedges are used to lift and support the foundation, preventing it from further sinking or settling. The process of underpinning can be complicated, which is why it's important to hire professional foundation repair experts.At the May 21st, 2007 dinner meeting hosted by the New York chapter of the ASME Met Section, Gerard Hillenbrand, P.E. discussed everything attendees always wanted to know about underpinning but were afraid to ask. He provided valuable information about the underpinning process, including when it is needed, the different methods used, and the benefits of underpinning.Underpinning is typically done when a foundation has experienced significant damage, such as cracks or settling. It's important to address these issues before they worsen and cause further problems. Underpinning is also necessary when there is a need to add new floors to a building or to increase the load capacity of an existing foundation.There are several methods used in underpinning, including the use of underpinning wedges. Other methods include pile underpinning, beam and base underpinning, and mass concrete underpinning. A foundation repair expert can determine which method is best for a particular situation.The benefits of underpinning are numerous. It can prevent further foundation damage, stabilize the foundation, and increase the load capacity of the foundation. Underpinning can also be used to level a foundation that has settled, making the building safer and more comfortable for occupants.In conclusion, underpinning is an important part of foundation repair. It involves strengthening a foundation that has been weakened by various factors. The use of underpinning wedges is a common method used in underpinning, and there are various other methods used as well. The benefits of underpinning include preventing further foundation damage, stabilizing the foundation, and increasing the load capacity of the foundation. If you are experiencing foundation issues, it is important to hire a professional foundation repair expert to assess the damage and recommend the best course of action.

High-Quality 2D Steel Welding Table for Efficient Workmanship

[Company Name], a leading manufacturer in the welding industry, has recently launched its newest product, the 2D Steel Welding Table. This innovative table is designed to provide precision and stability for welding projects, making it an essential tool for professionals and hobbyists alike.The 2D Steel Welding Table is made from high-quality steel, ensuring durability and longevity. Its flat surface and grid pattern make it ideal for securing workpieces during welding, allowing for accurate and seamless welding processes. The table also features adjustable height and tilt angles, providing versatility and convenience for various welding applications.As a company committed to delivering top-notch welding solutions, [Company Name] takes pride in its attention to detail and quality craftsmanship. The 2D Steel Welding Table is a testament to the company's dedication to innovation and excellence in welding equipment.The table's sturdy construction and practical design make it a valuable addition to any workshop or manufacturing facility. Whether it's for professional use in a fabrication shop or for DIY projects in a home garage, the 2D Steel Welding Table offers reliability and performance that meet the demands of today's welding industry.In addition to the 2D Steel Welding Table, [Company Name] also offers a wide range of welding equipment and accessories, including welding machines, protective gear, and welding consumables. With a focus on providing comprehensive solutions for welding professionals, the company continues to expand its product offerings to meet the evolving needs of the industry.Furthermore, [Company Name] is known for its dedication to customer satisfaction and technical support. The company's team of welding experts is committed to assisting customers with product selection, technical inquiries, and troubleshooting, ensuring that customers have a seamless experience with their welding equipment.The launch of the 2D Steel Welding Table underscores [Company Name]'s ongoing commitment to advancing the welding industry through innovative products and exceptional customer service. As the company continues to grow and expand its product line, it remains a trusted partner for welding professionals around the world.With the introduction of the 2D Steel Welding Table, [Company Name] is poised to set a new standard for precision and reliability in welding equipment. Whether for professional fabrication projects or personal DIY endeavors, this new product is sure to make an impact in the welding community.

Top Cast Iron Test Bed Plate Manufacturers and Suppliers in India - Verified List Available at Exporthub

India Cast Iron Test Bed Plate Manufacturers and SuppliersIndia has been one of the leading countries in the manufacturing and exporting of various industrial products. One of such products that India has gained enormous expertise and experience in over the years is cast iron test bed plates. Cast iron test bed plates are used in the mechanical and automotive industries to test the accuracy and flatness of various tools and machines. The quality of these cast iron test bed plates determines the accuracy and precision of the machines used in these industries.India has many manufacturers and suppliers of cast iron test bed plates. Let’s take a look at some of the top cast iron test bed plate suppliers from India.1. C. S. Machine Tools: C. S. Machine Tools is one of the leading manufacturers and suppliers of cast iron test bed plates in India. They have a wide range of products that cater to the needs of various industries. They provide customized solutions to their clients based on their specific requirements.2. Optical Flat: Optical Flat is a manufacturer and supplier of cast iron test bed plates based in Mumbai, India. They have over 30 years of experience in manufacturing high-quality cast iron test bed plates that are used in various industries. They specialize in providing customized solutions to their clients.3. Neco Castings: Neco Castings is a manufacturer and supplier of cast iron test bed plates based in Jaipur, India. They have been in the business for over 10 years and have extensive knowledge and expertise in manufacturing high-quality cast iron test bed plates. They provide customized solutions to their clients based on their specific requirements.4. Prakash Engitech: Prakash Engitech is a manufacturer and supplier of cast iron test bed plates based in Rajkot, India. They have been in the business for over 15 years and have extensive knowledge and expertise in manufacturing high-quality cast iron test bed plates. They provide customized solutions to their clients based on their specific requirements.5. Servecast Foundry: Servecast Foundry is a manufacturer and supplier of cast iron test bed plates based in Coimbatore, India. They have been in the business for over 20 years and have extensive knowledge and expertise in manufacturing high-quality cast iron test bed plates. They provide customized solutions to their clients based on their specific requirements.In conclusion, India has many manufacturers and suppliers of cast iron test bed plates. These manufacturers and suppliers have extensive knowledge and expertise in manufacturing high-quality cast iron test bed plates that are used in various industries. They provide customized solutions to their clients based on their specific requirements. India has earned a reputation for being a reliable and trustworthy source for cast iron test bed plates.

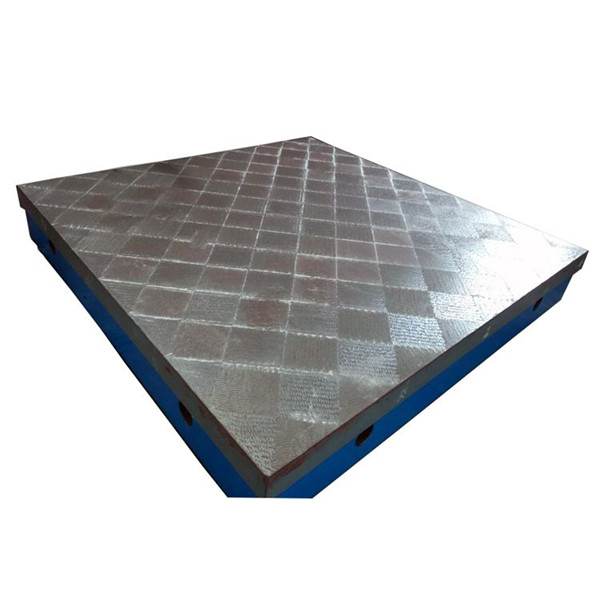

Benefits of Using T-Slotted Cast Iron Floor Plates for Industrial Applications

article:Cast Iron T Slotted Floor Plate: The Ultimate Solution for Industrial WorkshopsIndustrial workshops require specialized equipment to improve workflow and efficiency. A crucial part of the equipment includes workstations with high-performing floors to effectively carry out tasks and ensure workers' safety. This is where Cast Iron T Slotted Floor Plate comes in.The Cast Iron T Slotted Floor Plate is an essential equipment in industrial workshops and foundries. It is a flat, sturdy metal plate that rests on the workshop floor to provide a level, stable, and reliable base for heavy-duty machinery and equipment. The Cast Iron T Slotted Floor Plate is usually made from high-grade cast iron with T-slots milled into the plate to allow for secure and flexible clamping of tools, instruments, and machinery.These T-slots placed at regular intervals on the Cast Iron T Slotted Floor Plate make it an ideal solution for many workshop applications. The slots can be used to bolt tools to the floor, thus increasing the wrokstation's accuracy, efficiency and stability as compared to other methods.Each Cast Iron T Slotted Floor Plate is created with T-slots that are designed to ANSI and DIN standards, ensuring compatibility with most standard socket-head bolts. Also, the manufacturing process incorporates high-precision milling that guarantees a tight fit, thus eliminating movement or vibration in the work stations and ensuring safe working conditions.Industrial workshops often require materials that are resistant to environmental factors such as wear and tear, heavy loads, and extreme temperature changes. The Cast Iron T Slotted Floor Plate is able to withstand extreme temperatures change, making it perfect to withstand wear and tear over time. The Cast Iron T Slotted Floor Plate can also be machined to fit specific needs, reducing workshop downtime and enhancing work speed.Although Cast Iron T Slotted Floor Plates are useful for a wide range of applications, they are primarily used in CNC machines, welding tables, assembly lines, and mill processing. They are also suitable for heavy-duty induction hardening applications and are ideal for applications requiring substantial weight-bearing capacity.At their core, Cast Iron T Slotted Floor Plates are a measure of industrial workstations' efficiency and safety. They provide a stable platform for workers to carry out their tasks, secure clamping of tools, and reliable industrial equipment. Cast Iron T Slotted Floor Plates have become staples in industrial workplaces due to their versatility, durability, and precision.A well-manufactured Cast Iron T Slotted Floor Plate supports heavy machinery and equipment, eliminates harmful vibrations, and ensures the safety of all who use and service the machinery and equipment.Getting the best Cast Iron T Slotted Floor Plate requires experience and expertise. With diverse manufacturers across the world, such as the US-based Flint Machine Tools, selecting the right manufacturer is the first step in acquiring these cast iron plates.Flint Machine Tools has been reliably producing high-quality Cast Iron T Slotted Floor Plates that meet statutory guidelines since 2001. The company has a high-quality testing standard that ensures its Cast Iron T Slotted Floor Plates are of unparalleled quality. Their milling process of Cast Iron T Slotted Floor Plate offers perfect flatness, and their T-slots are effectively milled to the ANSI and DIN standards.To promote safety and precision in the workshop, Flint Machine Tools' Cast Iron T Slotted Floor Plate features countersunk holes to hide bolts' heads, ensuring a flush fit. Additionally, they are milled with accurately positioned T-slots, which offer flexibility in clamp positioning.In conclusion, Cast Iron T Slotted Floor Plate is an essential part of industrial workshops and foundries. With the versatility, resilience, and precision provided, the Cast Iron T Slotted Floor Plate is an important investment for workshop owners looking to enhance their work stations. As a trusted manufacturer of these essential plates, Flint Machine Tools has been a reliable supplier for over twenty years. Choosing their Cast Iron T Slotted Floor Plates will give workshop owners peace of mind as they work in a safe, stable, and efficient environment.

Ductile Cast Iron: A Versatile and Strong Construction Material

Title: Utilizing Advanced Ductile Cast Iron Technology to Drive Engineering ExcellenceIntroductionIn the fast-paced world of engineering, technological advancements play a pivotal role in creating innovative solutions. One such breakthrough is the incorporation of ductile cast iron, an industry-leading material renowned for its exceptional mechanical properties. This article will shed light on the cutting-edge applications of ductile cast iron while discussing the contributions of a prominent industry player. By combining advanced materials and engineering expertise, this company is propelling the industry towards new frontiers.Ductile Cast Iron: Unveiling its Strength and VersatilityDuctile cast iron, often referred to as nodular cast iron or spheroidal graphite iron, features unique properties that make it an ideal choice for a wide range of applications. Its primary characteristic is its high tensile strength, ensuring a durable and robust end product. The graphite nodules present in ductile cast iron greatly enhance its malleability, making it easier to machine and weld. These qualities, combined with excellent corrosion resistance and cost-effectiveness, make ductile cast iron a top choice for industries such as automotive, construction, and machinery manufacturing.Revolutionizing the Automotive IndustryAmong the industries benefitting from the numerous advantages of ductile cast iron, the automotive sector stands out in its use of this remarkable material. The ability to absorb vibrations and dampen noise makes ductile cast iron an indispensable element in enhancing the overall performance and safety of vehicles. In addition, this material's exceptional wear resistance and thermal conductivity significantly contribute to the longevity and efficiency of automobile components. With the automotive industry's increasing demand for lightweight, fuel-efficient vehicles, ductile cast iron emerges as a key contender in achieving these objectives without compromising on essential mechanical properties.Company Spotlight: A Leader in Ductile Cast Iron ProductionAs a pioneering force in the field of advanced materials, [Company Name] has made significant strides in harnessing the potential of ductile cast iron. With a rich history of over X years, [Company Name] has consistently displayed a commitment to innovation and excellence. Its dedicated research and development team has focused on refining the manufacturing processes to produce ductile cast iron of unparalleled quality.One of [Company Name]'s key achievements in the industry is the development of a proprietary method for casting ductile iron products. By utilizing an advanced metallurgical process, [Company Name] has succeeded in minimizing impurities, ensuring consistent mechanical properties, and improving overall productivity. This breakthrough technique has revolutionized the market, leading to increased efficiency and enhanced product performance across various end-user industries.Moreover, [Company Name] provides comprehensive services, offering tailored solutions to meet individual customer requirements. Its team of experienced engineers offers technical support and collaborates closely with clients to develop customized solutions. By building strong relationships based on trust and expertise, [Company Name] has become a preferred partner in the industry.Driving Innovation and SustainabilityIn addition to its groundbreaking achievements, [Company Name] demonstrates a strong commitment to environmental sustainability. Through the utilization of energy-efficient production processes and waste reduction strategies, the company strives to minimize its ecological footprint. By aligning its operations with stringent environmental standards and investing in state-of-the-art technology, [Company Name] leads the way in responsible manufacturing practices.Looking Ahead: Unleashing the Potential of Ductile Cast IronWith an ever-increasing focus on innovation, [Company Name] is poised to lead the industry towards new horizons. By continuously pushing the boundaries of ductile cast iron, this forward-thinking company showcases its commitment to engineering excellence. The unrivaled strength, versatility, and cost-effectiveness of ductile cast iron position it as a material of choice for a myriad of applications, ensuring a sustainable and prosperous future for the engineering industry.ConclusionDuctile cast iron's impressive mechanical properties and versatility are revolutionizing various industries, most notably the automotive sector. Through advancements in manufacturing techniques, industry leaders like [Company Name] have successfully harnessed the potential of this material, offering tailored solutions tailored to meet client-specific needs. With a focus on innovation, environmental stewardship, and sustainable growth, [Company Name] exemplifies the way forward in incorporating ductile cast iron into groundbreaking engineering endeavors.

Guide to Grey Cast Iron Castings: Properties, Uses, and Applications

Grey Cast Iron Castings, a leading manufacturer of high-quality cast iron products, has recently announced a significant expansion to their production facilities. The company, known for their commitment to superior craftsmanship and customer satisfaction, has been steadily gaining recognition in the industry for their exceptional products and outstanding service.With over [number] years of experience in the cast iron casting industry, Grey Cast Iron Castings has garnered a reputation for excellence. Their state-of-the-art facilities and advanced manufacturing processes have allowed them to produce a wide range of cast iron products, including [list of products]. Their dedication to quality and precision has earned them the trust and loyalty of a diverse clientele, including companies in the automotive, agricultural, and construction sectors.The recent expansion of Grey Cast Iron Castings' production facilities is a testament to their continued growth and success. The company has invested in new equipment and technology to increase their production capacity and meet the growing demand for their products. This expansion will also create new job opportunities in the local community and contribute to the overall economic development of the region.In addition to their commitment to excellence in manufacturing, Grey Cast Iron Castings is also dedicated to environmental sustainability. They have implemented eco-friendly practices in their production processes and are constantly exploring new ways to reduce their environmental impact. By using recycled materials and minimizing waste, they strive to be a responsible corporate citizen and contribute to a more sustainable future.The company's success can be attributed to their team of skilled and experienced professionals who are passionate about their work. Grey Cast Iron Castings' employees undergo rigorous training and adhere to strict quality control measures to ensure that every product meets the highest standards. Their emphasis on continuous improvement and innovation has allowed them to stay ahead of the competition and maintain their position as a leading provider of cast iron products.Grey Cast Iron Castings is also dedicated to building strong and enduring relationships with their customers. They understand the unique needs of each client and work closely with them to develop customized solutions that meet their specific requirements. Their commitment to customer satisfaction has earned them a loyal customer base and a solid reputation for reliability and integrity in the industry.As Grey Cast Iron Castings continues to expand and innovate, they remain focused on upholding the values that have guided them since their inception. Their dedication to quality, sustainability, and customer-centric approach sets them apart as a trusted partner in the cast iron casting industry. With their recent expansion, they are well-positioned to continue exceeding the expectations of their customers and solidify their standing as a leader in the market.

Top Cast Iron Test Bed Plate Suppliers in India - Verified Manufacturers and Suppliers for Cast Iron Plates and Griddles

India has always been a hub for manufacturing and supplying high-quality industrial equipment, and the Cast Iron Test Bed Plate is no exception. The Cast Iron Test Bed Plate is a crucial component used in various industries, including manufacturing, engineering, and construction. It serves as a stable and flat surface for testing, calibrating, and aligning various machines and equipment.In this blog post, we will take a look at the top Cast Iron Test Bed Plate suppliers in India and their products.1. M/s Bhawani Industries Private LimitedM/s Bhawani Industries Private Limited is one of the leading manufacturers and suppliers of Cast Iron Test Bed Plate in India. They offer a wide range of Cast Iron Test Bed Plates that are precision engineered and built to last. Their Cast Iron Test Bed Plates have a smooth surface finish and are available in various sizes and dimensions.2. P.A. Steel Co.P.A. Steel Co. is another prominent manufacturer and supplier of Cast Iron Test Bed Plates in India. They offer a wide variety of Cast Iron Test Bed Plates that are suitable for use in different industries. Their Cast Iron Test Bed Plates are known for their durability, stability, and superior quality.3. Dalal Engineering Pvt. Ltd.Dalal Engineering Pvt. Ltd. is a well-known manufacturer and exporter of Cast Iron Test Bed Plates in India. They have a team of skilled professionals who use advanced technology and machinery to create high-quality Cast Iron Test Bed Plates. Their Cast Iron Test Bed Plates are corrosion-resistant and have a long service life.4. Shiv Shakti Engineering WorksShiv Shakti Engineering Works is a reputable manufacturer and supplier of Cast Iron Test Bed Plates in India. They offer a wide range of Cast Iron Test Bed Plates that are made from high-grade cast iron and are available in various shapes and sizes. Their Cast Iron Test Bed Plates are known for their excellent finish, durability, and high strength.5. H C & CompanyH C & Company is a well-established manufacturer and supplier of Cast Iron Test Bed Plates in India. They provide various types of Cast Iron Test Bed Plates that are known for their high load-bearing capacity, smooth surface finish, and corrosion resistance. Their Cast Iron Test Bed Plates are suitable for various industrial applications and can withstand extreme temperatures and weather conditions.ConclusionThe Cast Iron Test Bed Plate is an essential component used in various industries, including manufacturing, engineering, and construction. There are several Cast Iron Test Bed Plate suppliers in India, and we have listed the top five in this blog post. When choosing a supplier for your Cast Iron Test Bed Plate needs, always look for a company that provides high-quality products, excellent customer service, and affordable prices.

Ultimate Guide to Finding the Best Quality Spare Parts for Granite Machines

Granite Machine Spare Parts: A Leading Company in the Manufacturing IndustryGranite Machine Spare Parts is a leading manufacturer of high-quality granite machine spare parts. Established in 1994, the company has been providing its products to a wide range of customers around the world. With over two decades of experience, the company has developed a reputation for delivering top-quality products that meet the highest industry standards.The company is headquartered in a state-of-the-art facility located in China. This modern facility is equipped with the latest technology to ensure that all production processes are efficient and effective. The company also has a team of highly skilled professionals who work tirelessly to ensure that all products are of the highest quality.At Granite Machine Spare Parts, customers come first. The company is committed to providing exceptional customer service and making sure that customers are completely satisfied with their products. The company's team of sales representatives are highly knowledgeable about the products and can provide expert advice and guidance to customers.The company's product range is vast and includes a variety of machine spare parts, including spindles, bearings, belts, pulleys, and much more. The company's products are designed to meet the specific needs of different customers and are available in various sizes and specifications. The company uses only the highest quality raw materials to ensure that all products meet the highest industry standards.Granite Machine Spare Parts has been at the forefront of innovation in the manufacturing industry. The company invests heavily in research and development to ensure that its products are always cutting-edge and meet the changing needs of its customers. The company's team of engineers is constantly looking for new ways to improve products and manufacturing processes to make them more efficient and cost-effective.The company's commitment to quality is demonstrated by its adherence to strict quality control measures. All products undergo rigorous testing to ensure that they are of the highest quality before being shipped to customers. The company is also ISO 9001 certified, which is a testament to its commitment to quality.Granite Machine Spare Parts also places great emphasis on environmental sustainability. The company employs environmentally friendly manufacturing processes and uses materials that are safe for the environment. The company's commitment to sustainability is one of the many reasons why it has become a leading player in the manufacturing industry.In conclusion, Granite Machine Spare Parts is a leading manufacturer of high-quality granite machine spare parts. With over two decades of experience, the company has developed a reputation for delivering top-quality products that meet the highest industry standards. The company's commitment to quality, innovation, customer service, and sustainability has made it a trusted partner to a wide range of customers around the world. The company's focus on excellence and continuous improvement is sure to keep it at the forefront of the manufacturing industry for many years to come.

Triangular Ruler Made of Cast Iron Now Available for Precision Measurements

The Cast Iron Triangular Ruler is a tool that has long been used in construction and engineering industries. This essential tool is commonly used for measuring angles, lengths, and heights. A company that produces this particular style of ruler has recently introduced an innovative new version to the market.The triangular ruler serves as a vital tool for professionals in engineering and construction fields. Its design is not only iconic, but it provides functionality, accuracy, and durability. The triangular ruler is essential because it allows the user to measure angles that traditional rulers cannot measure accurately. As a result, it is considered an essential tool in any engineer or architect's toolbox.One company that has been at the forefront of the production of the Cast Iron Triangular Ruler has recently innovated the product. The new ruler offers better features and user-friendliness than its predecessors. The new triangular ruler has been designed with an ergonomic grip and is made up of high-precision materials that ensure accuracy in all measurements.The unique design of the new triangular ruler also provides added stability, which is critical in making precise measurements. The company has used its years of experience acquired through ongoing research and development to create an innovative triangular ruler that is both practical and versatile.The Cast Iron Triangular Ruler is an excellent tool that provides accuracy and stability to the construction industry. The new model offers new additions that go above and beyond expectations, providing unparalleled quality and ease of use. The product has already achieved positive feedback from its users, who praise it for its sturdiness and precision.The company that produces the new triangle ruler is focused on delivering quality and providing precise solutions to industry professionals. The company has put special emphasis on the materials used to produce the ruler, ensuring the end product is both durable and long-lasting. The quality of the product is paired with the company's commitment to great customer service, enhancing their reputation as a reliable and trustworthy supplier.The company behind the Cast Iron Triangular Ruler prides itself on its high attention to detail. They believe in offering their clients superior quality and are committed to providing exceptional experiences through every stage of the purchase process. This dedication to quality provides valuable reassurance to customers, giving them confidence in the products they purchase.The company also provides a professional service center. In this center, they offer tips and advice regarding the proper use of their products, helping customers make full use of their purchases. This support has contributed to the company's excellent reputation in the industry, providing a valuable resource to its customers.In conclusion, the Cast Iron Triangular Ruler is an essential tool that has been around for decades. The latest innovation of this classic tool is a testament to industry professionals' dedication and commitment, seeking better ways of doings things. With the introduction of a superior product, customers can have confidence in their measurements, knowing that they are using a special tool that has been engineered for accuracy, durability, and precision. The company's consistent commitment to quality and exceptional customer service ensures clients get the best experience and value for their investment. The release of the new Cast Iron Triangular Ruler model is a game-changer that will have a considerable impact on the industry and offers a highly useful tool to professionals that is built to last.