Discover the Benefits of Right Angle Wedges for Your Needs

By:Admin

With a wide range of styles and colors to choose from, Right Angle Wedges offers something for everyone. From classic neutrals to bold and vibrant hues, their shoes are designed to suit a variety of tastes and occasions. The company’s dedication to creating high-quality, durable footwear has earned them a loyal following of customers who appreciate the value and style of their products.

In addition to their commitment to quality, Right Angle Wedges also emphasizes the importance of comfort. Their shoes are designed with a focus on providing support and stability, making them ideal for everyday wear. Whether you’re running errands or heading out for a night on the town, you can count on Right Angle Wedges to keep your feet feeling great all day long.

One of the brand’s most popular designs is their signature wedge heel. This style offers a stylish lift without sacrificing comfort, making it a favorite among those who want to add a little extra height to their look. The wedge heel is also versatile, pairing well with everything from jeans to dresses, making it a go-to option for any occasion.

In addition to their wedge heels, Right Angle Wedges also offers a variety of other styles, including flats, sandals, and boots. Whether you prefer a casual and laid-back look or something more polished and professional, you can find the perfect shoe to fit your needs from the brand’s extensive collection.

Right Angle Wedges is also committed to sustainability and ethical production practices. They prioritize using eco-friendly materials and ethical manufacturing methods to create their shoes, ensuring that their products have a minimal impact on the environment. This dedication to sustainability has resonated with eco-conscious consumers, further solidifying the brand’s reputation as a responsible and forward-thinking footwear company.

Furthermore, Right Angle Wedges has also been praised for its dedication to inclusivity and diversity. The brand offers a wide range of sizes to accommodate different foot shapes and has featured a diverse range of models in its marketing campaigns. This commitment to inclusivity has made the brand popular among consumers who value representation and diversity in the fashion industry.

As Right Angle Wedges continues to grow and expand its product offerings, the brand shows no signs of slowing down. With an unwavering commitment to quality, comfort, sustainability, and inclusivity, the company is well-positioned to become a leading force in the footwear industry. Whether you’re in the market for a stylish pair of wedges, comfortable sandals, or versatile flats, you can count on Right Angle Wedges to deliver on all fronts. With their dedication to creating stylish, comfortable, and sustainable footwear, it’s no wonder that the brand has become a favorite among fashion-conscious consumers.

Company News & Blog

Durable Welding Jig Table for Precision Fabrication Work

ABC Manufacturing, a leading company in the field of metal fabrication, has recently launched a new product that is set to revolutionize the welding industry. The product, known as the Welding Jig Table, is designed to assist welders in creating precise and accurate welds, resulting in high-quality and consistent finished products.The Welding Jig Table is a versatile and multi-functional tool that provides a stable and secure platform for welding various metal components. It is equipped with a range of features that make it an essential piece of equipment for any welding operation. The table is constructed from high-quality materials, ensuring durability and longevity in the workshop.One of the key features of the Welding Jig Table is its adjustable and customizable design. The table comes with a variety of clamp and fixture options, allowing for the secure and accurate positioning of workpieces. This level of flexibility ensures that welders can work with a wide range of metal components, regardless of their size or shape.Furthermore, the Welding Jig Table is equipped with a grid pattern on its surface, which serves as a guide for precise alignment and welding. This feature assists in ensuring that welds are consistently accurate, reducing the likelihood of errors and rework. The table also includes a number of integrated tools and accessories, making it a comprehensive solution for all welding needs.The team at ABC Manufacturing has designed the Welding Jig Table with the user in mind. Its user-friendly interface and ergonomic design make it easy to operate and adjust, reducing downtime and increasing productivity in the workshop. The table also promotes safety by providing a stable and secure platform for welding, minimizing the risk of accidents and injuries.In addition to its functional benefits, the Welding Jig Table is also designed to be a cost-effective solution for welders. Its durable construction and long-lasting components ensure that it is a worthwhile investment for any welding operation. By streamlining the welding process and improving the quality of finished products, the table enables businesses to reduce waste and rework, ultimately saving time and money.ABC Manufacturing takes great pride in its commitment to quality and innovation. The development of the Welding Jig Table is a testament to the company's dedication to providing cutting-edge solutions for the metal fabrication industry. With a team of experienced engineers and designers, ABC Manufacturing continues to push the boundaries of what is possible in the field of welding equipment.The launch of the Welding Jig Table has generated significant interest within the welding community, with many industry professionals recognizing its potential to revolutionize the way welders work. The product has already received positive feedback from early adopters, who have praised its functionality and performance.For businesses looking to improve the quality and efficiency of their welding operations, the Welding Jig Table offers a compelling solution. With its innovative design and comprehensive features, the table is set to become an essential tool for any welding workshop.As ABC Manufacturing continues to lead the way in metal fabrication, the Welding Jig Table stands as a testament to the company's commitment to delivering high-quality and innovative solutions for the industry. With its potential to streamline welding processes and improve the quality of finished products, the table is poised to make a significant impact in the world of metal fabrication. As the demand for precise and consistent welds continues to grow, the Welding Jig Table is well-positioned to meet the needs of welders and businesses alike.

High-quality and Durable 4'x3' Welding Table with Nitride Finish - Resistant to Weld Spatter, Corrosion and Wear - Shop Now!

The Importance of Using a Nitriding Steel Welding TableWhen it comes to welding, having a stable and secure surface to work on is crucial. Welding involves joining two pieces of metal together, and this requires heat, pressure, and a lot of focus. Without a proper welding table, the process can become difficult and cumbersome, resulting in mistakes and less-than-optimal results.This is where nitriding steel welding tables come in handy. These tables are designed specifically for welding, and they offer a wide range of benefits to the user. Here are some of the reasons why you should consider using a nitriding steel welding table for your next welding project.1. Resistance to Weld SpatterOne of the biggest challenges of welding is the spatter that comes from the welding process. This spatter can damage the surface of the table and make it difficult to work on. Nitriding steel welding tables are designed to resist this spatter, thanks to the nitride finish that covers the surface. This finish is highly resistant to corrosion and wear, and it helps to protect the table from damage caused by spatter.2. Stability and DurabilityIn addition to being resistant to spatter, nitriding steel welding tables are also incredibly stable and durable. Welding requires a lot of pressure and force, and a table that isn't sturdy enough can cause the welding process to become unstable and difficult. Nitriding steel tables are built to handle this pressure, and they are also resistant to warping and bending over time.3. Easy to Set Up and Tear DownAnother benefit of nitriding steel welding tables is that they are easy to set up and tear down. This is particularly important if you need to move the table from one location to another. With a nitriding steel table, you can quickly and easily disassemble the table and move it to a new location, without worrying about damaging the surface or losing stability.4. VersatilityFinally, nitriding steel welding tables are incredibly versatile and can be used for a wide range of welding projects. Whether you're working on a small-scale project or a larger one, a nitriding steel table can handle the job. Additionally, because of its durability and resistance to wear, a nitriding steel table can last for many years, making it a worthwhile investment.In conclusion, if you're looking for a stable, durable, and versatile surface to work on for your welding projects, a nitriding steel welding table is an excellent option to consider. With its resistance to spatter, stability and durability, ease of set up and tear down, and versatility, you can rest assured that your welding process will be smooth and successful every time.

High-Quality Machine Components for Granite Materials

Granite Machine Components, a leading manufacturer of high-quality machine components, is proud to announce the launch of their latest line of products designed to meet the needs of modern manufacturing industries. The company, which has been in operation for over two decades, is known for its commitment to excellence and innovation in the field of machine component manufacturing. With the introduction of their new line of products, Granite Machine Components continues to demonstrate their dedication to providing cutting-edge solutions to their customers.The new line of products from Granite Machine Components includes a wide range of machine components, including precision-ground granite surface plates, granite squares, granite parallels, and granite straight edges. These components are designed to provide accurate and reliable measurements for a variety of industrial applications, making them an essential tool for today's manufacturing industry. With their superior quality and durability, these components are built to withstand the rigorous demands of modern manufacturing environments.Granite Machine Components has earned a strong reputation for delivering high-quality products that meet the industry's stringent standards. Their team of highly skilled engineers and technicians work tirelessly to ensure that each product meets the company's exacting standards for precision and performance. By leveraging advanced technology and innovative manufacturing processes, Granite Machine Components has continually raised the bar for excellence in the industry."We are thrilled to introduce our new line of products, which represent the latest advancements in machine component manufacturing," said the CEO of Granite Machine Components. "Our goal is to provide our customers with the most reliable and accurate components that will help them optimize their manufacturing processes and achieve greater efficiency. With our new line of products, we are confident that we can meet and exceed the needs of our customers, and we look forward to continuing to lead the industry in delivering top-quality machine components."In addition to their commitment to producing high-quality products, Granite Machine Components also places a strong emphasis on customer satisfaction. The company prides itself on its responsive and knowledgeable customer service team, which is dedicated to providing support and assistance to customers throughout the entire purchasing process. Whether it's helping customers select the right components for their specific needs or providing technical support after purchase, Granite Machine Components is committed to ensuring that every customer is completely satisfied with their experience.As a company with a strong focus on innovation and continuous improvement, Granite Machine Components is constantly exploring new ways to enhance their products and processes. Their research and development team is dedicated to staying at the forefront of advancements in the industry, enabling the company to anticipate and meet the evolving needs of their customers. With a strong emphasis on staying ahead of the curve, Granite Machine Components is well-positioned to continue leading the industry in providing state-of-the-art machine components.With the launch of their new line of products, Granite Machine Components is poised to further solidify its position as a premier provider of machine components to the manufacturing industry. By delivering products that offer unmatched precision, durability, and reliability, the company is helping its customers achieve greater success in their respective industries. As they continue to push the boundaries of what is possible in machine component manufacturing, Granite Machine Components remains dedicated to providing the highest level of quality and service to its customers.

How to Properly Calibrate a Granite Surface Plate

Granite Surface Plate Calibration Company Offers Comprehensive Services for Precision Measurements and CalibrationPrecision is the cornerstone of any industry that involves measurements, and the accuracy and quality of the measuring equipment is crucial for achieving consistent and reliable results. Ensuring that measuring equipment is properly calibrated is essential for maintaining accuracy, and one company that has made a name for itself in this field is the Granite Surface Plate Calibration Company.The Granite Surface Plate Calibration Company is a leader in the field of calibration and precision measurements for a variety of industries. With years of experience, state-of-the-art equipment, and a team of highly skilled technicians, this company offers comprehensive services for the calibration of measuring and testing equipment, including granite surface plates.Granite surface plates are essential tools in many industrial applications, including metalworking, woodworking, and precision machining, as well as in research and development activities. The accuracy and quality of these plates are critical for achieving desired results in many processes, including precision manufacturing and inspection.To ensure the accuracy and reliability of granite surface plates, the Granite Surface Plate Calibration Company offers a range of calibration services, starting with a detailed inspection of the plates to identify any areas of damage or wear. The next step is to use state-of-the-art calibration equipment to accurately measure the flatness, levelness, and surface texture of the plates. These measurements are then compared to established standards to determine whether the plate is within acceptable tolerances.If any adjustments are needed, the company's technicians have the skills and equipment necessary to perform precision machining or grinding operations to bring the plate back into spec. Once the calibration process is complete, the company issues a calibration certificate that provides detailed information about the calibration process, the results achieved, and any adjustments made.In addition to granite surface plate calibration, the company also offers calibration services for a variety of other measuring and testing equipment, including precision balances, force gages, pin gauges, and more. Whether you need to calibrate a single piece of equipment or an entire lab, the company's technicians have the expertise and equipment needed to get the job done right.The Granite Surface Plate Calibration Company is committed to providing its customers with the highest level of quality and accuracy in every aspect of its service. From its state-of-the-art equipment and tools to its skilled and experienced technicians, the company has everything needed to ensure that your measuring and testing equipment is calibrated to the highest standards.Furthermore, the company offers convenient pickup and delivery services to minimize downtime for customers, and its pricing is highly competitive, making it an excellent value for businesses of all sizes.Whether you are looking to calibrate a single piece of equipment or an entire lab, the Granite Surface Plate Calibration Company is the name to trust for precision measurements and calibration services. Contact them today to learn more about the services they offer and to schedule a consultation with one of their experts.

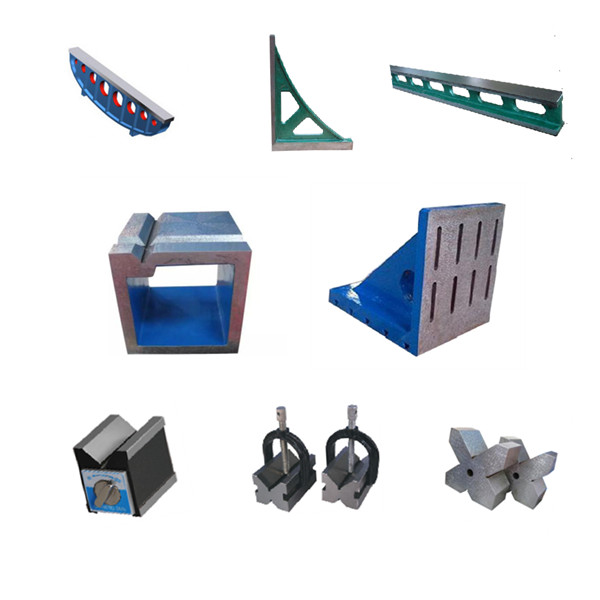

How to Use a V Block Professional for Granite Cutting

Innovative V-Block Precision Tool Revolutionizes Manufacturing IndustryIn a world where precision and accuracy are paramount, the manufacturing industry is constantly seeking out new and innovative technologies to improve efficiency and quality. This search has led to the development of the groundbreaking V-Block Precision Tool, a product that is set to revolutionize the industry.The V-Block Precision Tool is a state-of-the-art device that is designed to provide high-precision measurement and alignment for a wide range of applications. With its unique granite construction and precision-machined surfaces, this tool offers unparalleled stability and accuracy, making it an essential addition to any manufacturing operation.The V-Block Precision Tool is the brainchild of a cutting-edge company that has been at the forefront of precision measurement and alignment technology for over two decades. Their dedication to innovation and quality has made them a trusted leader in the industry, and the development of the V-Block Precision Tool is yet another testament to their commitment to excellence.This company has a long-standing reputation for delivering top-notch products and services to their clients across various industries. With a team of expert engineers and technicians, they have consistently demonstrated their ability to push the boundaries of what is possible in precision measurement and alignment.The V-Block Precision Tool is the result of extensive research and development, and it has been engineered to meet the highest standards of quality and performance. Its granite construction provides exceptional stability and durability, ensuring that it can withstand the rigors of industrial use while maintaining its precision and accuracy.One of the key features of the V-Block Precision Tool is its versatility. It can be used in a wide range of applications, from machining and assembly to inspection and testing. This versatility makes it an invaluable tool for any manufacturing operation, allowing for quick and accurate measurement and alignment across various processes.In addition to its precision and versatility, the V-Block Precision Tool also offers unmatched ease of use. Its intuitive design and user-friendly interface make it accessible to operators of all skill levels, allowing them to take full advantage of its capabilities without the need for extensive training or expertise.The introduction of the V-Block Precision Tool is set to bring about a significant shift in the manufacturing industry. Its ability to provide high-precision measurement and alignment in a wide range of applications will streamline processes, improve efficiency, and ultimately lead to higher-quality products.Furthermore, the V-Block Precision Tool is poised to have a positive impact on the bottom line for manufacturing operations. By reducing the time and resources required for measurement and alignment, it will help to lower production costs and increase overall productivity, ultimately leading to improved competitiveness in the market.The unveiling of the V-Block Precision Tool is a significant milestone for the company behind it, and it serves as a reminder of their ongoing commitment to innovation and excellence. With this groundbreaking product, they are once again demonstrating their ability to push the boundaries of what is possible in precision measurement and alignment.In conclusion, the V-Block Precision Tool is a game-changer for the manufacturing industry. Its unparalleled stability, accuracy, versatility, and ease of use make it an essential tool for any manufacturing operation seeking to improve efficiency and quality. With the introduction of this groundbreaking product, the company behind it is reaffirming its position as a leader in precision measurement and alignment, and is setting a new standard for the industry as a whole.

Calibrating Granite Surface Plates Outside of Workplace: A Feasibility Study Has your granite surface plate been calibrated outside of your Q.C lab? Find out if this is a viable option and learn tips for safe transportation.

Granite Reference Plate Calibration and Transportation to QC LabGranite reference plates are used in various industries for precision measurement of equipment or parts. These plates are made from high-quality granite and calibrated to ensure accurate measurements. However, over time, the granite surface may become worn or damaged, which requires recalibration to maintain accuracy.In some cases, calibration of a granite reference plate may be done outside the workplace laboratory. This involves sending the granite plate to a calibration center where it is inspected and recalibrated. However, the granite plate needs to be transported back to the Q.C. lab once the calibration is complete.Transporting a granite reference plate requires careful attention to prevent any damage or changes that might affect its calibration and accuracy. Here are some tips to ensure safe transportation of a granite reference plate:1. Secure Packaging: The granite reference plate should be properly packed to avoid any damages during transportation. Use bubble wrap, foam padding or any other appropriate packaging materials to protect the plate from scratches or breakage.2. Temperature control: Granite reference plates are sensitive to temperature changes. They should be kept in a controlled temperature environment to avoid any thermal expansion or contraction during transportation.3. Specialist transport: Use specialist transport companies or courier services that have experience in handling and transporting granite reference plates.4. Insurance: It is important to insure the granite reference plate during transportation to protect against any damages or loss. This will help cover the cost of repair or replacement should any damage occur.Once the granite reference plate is transported to the Q.C lab, it should be carefully inspected to ensure that it has not suffered any damage during transportation. The plate should also be recalibrated to re-establish its accuracy.In conclusion, recalibrating a granite reference plate outside the workplace laboratory and the subsequent transportation of the plate to the lab requires careful handling. Taking care to follow these tips will help maintain the plate’s calibration and accuracy, thus ensuring accurate measurements of equipment or parts.

High-Quality Granite Slabs for Your Kitchen Remodel in Maryland - Order Now!

Granite Slabs: A Timeless Addition to Your KitchenThe kitchen is the heart of every home. It’s where meals are cooked, families bond and memories are made. As the kitchen is such an important space, it’s essential to have it designed in a way that reflects your style and personality. One of the best ways to achieve this is by installing granite slabs.Granite is a type of natural stone that has been used for centuries. It’s a popular choice for kitchen countertops because it’s durable, heat-resistant and easy to maintain. But why stop at just countertops? Granite slabs can be used for a variety of purposes in your kitchen, from backsplashes to flooring.At KNC Granite, we offer the top-rated granite slabs in Maryland. Our slabs come in a variety of colors and patterns, allowing you to choose the perfect one for your kitchen. Here are some of the benefits of having granite slabs in your kitchen:DurabilityGranite is one of the most durable materials available for kitchen surfaces. It’s resistant to scratches, heat, and stains, making it perfect for busy kitchens. With proper care, your granite slabs can last for decades, making it a smart investment.Easy MaintenanceGranite is very easy to maintain. All you need to do is wipe it down with a damp cloth and mild soap to keep it looking new. Unlike other materials that require regular sealing and polishing, granite slabs require minimal upkeep.Timeless AppealGranite has been used in kitchens for centuries and it continues to be a popular choice today. Its timeless appeal means that it won’t go out of style anytime soon. Whether your kitchen is contemporary or traditional, granite slabs will complement any design.VersatilityGranite slabs can be used for a variety of purposes in your kitchen. They can be used as countertops, backsplashes, flooring, and even as decorative accents. With so many options to choose from, you can create a cohesive look throughout your kitchen.Small Granite Surface PlateIf you’re not ready to commit to a full kitchen renovation, a small granite surface plate is a great option. It can be used as a cutting board, cheese board, or even as a decorative piece on your kitchen island. A small granite surface plate is a budget-friendly way to add the beauty and durability of granite to your kitchen.In conclusion, granite slabs are a timeless addition to any kitchen. At KNC Granite, we offer the top-rated granite slabs in Maryland. With our variety of colors and patterns, you’re sure to find the perfect granite slab for your kitchen. Whether you’re looking to replace your countertops or add a small granite surface plate, we’ve got you covered. Contact us today to learn more about our granite slabs and to schedule a consultation.

Cast Iron Floor Plate Pricelist and Pricing Information

In a competitive market where precision and durability are paramount, the importance of high-quality cast iron floor plates cannot be overstated. These products play a crucial role in a wide range of industries, from manufacturing and engineering to construction and automotive. As such, the demand for reliable and top-notch floor plates is always on the rise.This is where {Company Name} comes in. With years of experience and a sterling reputation in the industry, {Company Name} has established itself as a leading supplier of precision cast iron floor plates. The company is known for its commitment to excellence and its unwavering dedication to meeting the unique needs of its clients.One of the key factors behind {Company Name}'s success is its unwavering focus on delivering top-notch products at competitive prices. With a keen understanding of market dynamics and a pulse on industry trends, {Company Name} has managed to stay ahead of the curve, consistently delivering products that meet and exceed industry standards.In line with its commitment to excellence, {Company Name} has recently announced a pricelist for its precision cast iron floor plates. This move is aimed at providing greater transparency to its clients and ensuring that they have access to the best products at the most competitive prices. The pricelist covers a wide range of floor plates, catering to the diverse needs of various industries.One of the standout features of {Company Name}'s pricelist is its competitive pricing. Despite the high quality and precision engineering that goes into its products, {Company Name} has managed to keep its prices relatively low, making its floor plates accessible to a wide range of clients. This commitment to affordability has endeared {Company Name} to its clients, many of whom have come to rely on the company as their go-to supplier for precision cast iron floor plates.In addition to its competitive pricing, {Company Name} also offers a diverse range of floor plates, catering to different specifications and requirements. Whether clients are looking for standard sizes or custom dimensions, {Company Name} has the capability to deliver, thanks to its advanced manufacturing facilities and a team of skilled engineers and technicians.Another factor that sets {Company Name} apart from its competitors is its unwavering commitment to customer satisfaction. The company understands that each client has unique needs and requirements, and as such, it goes the extra mile to provide personalized solutions that meet these needs. From offering expert advice and guidance to delivering products on time and within budget, {Company Name} has built a reputation for reliability and dependability.It's worth noting that {Company Name} prides itself on its adherence to strict quality control measures. Each and every floor plate that leaves its facilities undergoes rigorous testing and inspection to ensure that it meets the highest standards of quality and precision. This commitment to quality has earned {Company Name} the trust and confidence of its clients, who continue to rely on the company for their floor plate needs.In conclusion, {Company Name}'s pricelist for precision cast iron floor plates is a testament to the company's unwavering commitment to excellence, affordability, and customer satisfaction. By offering competitive prices, a diverse range of products, and unmatched quality, {Company Name} has set itself apart as a leader in the industry. As the demand for high-quality floor plates continues to rise, {Company Name} stands ready to meet the needs of its clients, providing them with top-notch products that they can rely on.