Durable and Reliable Inspection Tables for Granite Materials

By:Admin

In today's fast-paced and competitive manufacturing industry, ensuring the quality of products is of utmost importance. With the increasing demand for high-quality goods, manufacturers are continually seeking innovative solutions to meet these standards. One such innovative solution that has been making waves in the industry is the granite inspection table.

The granite inspection table, a vital tool for quality control purposes, has been gaining popularity in the manufacturing sector due to its precision, durability, and accuracy. These tables are significant in ensuring that all products meet specific quality standards before they are sent out to consumers. The sturdiness and stability of these tables make them ideal for conducting precise measurements and inspections of parts and components in various industries, including automotive, aerospace, electronics, and more.

One company that has been at the forefront of providing high-quality granite inspection tables is {Company Name}. Since its establishment, {Company Name} has been committed to delivering top-notch inspection tables to manufacturers worldwide. The company's dedication to quality, innovation, and customer satisfaction has solidified its position as a trusted supplier in the industry.

{Company Name} takes pride in its state-of-the-art manufacturing facility, where each granite inspection table is meticulously crafted to meet the exacting standards of its clients. Using advanced machinery and the finest materials, {Company Name} ensures that its inspection tables are not only durable and precise but also tailored to meet the specific needs of its customers.

One of the key features that sets {Company Name}'s granite inspection tables apart from the competition is their superior flatness and stability. Made from high-quality granite that is resistant to wear, corrosion, and temperature changes, these tables provide an exceptional surface for accurate measurements and inspections. Furthermore, {Company Name} offers a variety of customization options, including size, shape, and surface finish, to accommodate the unique requirements of different manufacturing processes.

The use of granite inspection tables has proven to be instrumental in enhancing the efficiency and accuracy of quality control procedures in the manufacturing industry. Manufacturers who have integrated these tables into their operations have reported significant improvements in their inspection processes, leading to higher product quality and overall customer satisfaction.

In addition to providing standard granite inspection tables, {Company Name} also offers ancillary products and accessories to complement the tables, such as precision measurement tools, angle plates, and clamping systems. This comprehensive approach to quality control equipment underscores {Company Name}'s commitment to being a one-stop solution provider for manufacturers seeking to elevate their quality control standards.

As the manufacturing industry continues to evolve and demand for superior quality products increases, the role of granite inspection tables in ensuring product quality and consistency is expected to become even more critical. Manufacturers who invest in high-quality inspection tables can gain a competitive edge by streamlining their quality control processes and delivering products that meet or exceed industry standards.

In conclusion, the rise of granite inspection tables has transformed the way manufacturers approach quality control, and {Company Name} has been a driving force behind this transformation. With its dedication to excellence and innovation, {Company Name} has established itself as a leading provider of top-of-the-line granite inspection tables, setting a new standard for quality control in the manufacturing industry. As businesses continue to prioritize quality and precision, the demand for these essential tools is only set to grow, and companies like {Company Name} are well-equipped to meet this demand with their cutting-edge solutions.

Company News & Blog

Quality Measuring Tool Factory Creates High Precision Granite Tools

Granite Measuring Tool Factory Joins Forces with Industry LeaderIn an exciting development for the precision measurement industry, Granite Measuring Tool Factory (GMTF) has announced a strategic partnership with an industry leader in the field. The collaboration between GMTF and this renowned company promises to bring about innovative solutions and improved capabilities in the production of high-quality measuring tools.GMTF, located in [location], has been a leading manufacturer of granite measuring tools for more than a decade. The company has established a strong reputation for producing precision granite surface plates, inspection surface plates, and other measurement solutions that are essential for industries such as aerospace, automotive, and manufacturing. With a commitment to quality, accuracy, and customer satisfaction, GMTF has set itself apart as a reliable partner for businesses that require precise measurements in their operations.The partnership between GMTF and the industry leader is expected to further enhance the capabilities of both companies. By combining their expertise, resources, and technologies, they aim to develop new and improved measurement tools that will meet the evolving needs of their customers. This collaboration will also enable them to leverage each other's strengths to explore new markets and expand their reach globally."We are thrilled to announce this partnership with [industry leader]," said the CEO of GMTF. "This union represents a significant milestone for our company and the precision measurement industry as a whole. By joining forces with [industry leader], we are poised to achieve new heights in innovation and customer satisfaction."The collaboration is set to bring about several benefits for GMTF and its customers. The company will gain access to advanced technologies and resources that will enable them to enhance the quality and performance of their granite measuring tools. This, in turn, will result in improved accuracy, reliability, and durability of their products, further strengthening GMTF's position as a preferred supplier of precision measuring solutions.Additionally, the partnership will allow GMTF to expand its product portfolio, offering a wider range of measurement tools to cater to the diverse needs of its customers. With access to new technologies and innovations, the company will be able to develop cutting-edge solutions that meet the stringent requirements of industries that rely on precise measurements for their operations.Customers can expect to benefit from the collaboration through the availability of an expanded range of high-quality measurement tools that are designed to meet their specific needs. Whether they require precision granite surface plates, inspection surface plates, or other measurement solutions, GMTF will be well-positioned to deliver products that exceed their expectations.Another key aspect of the partnership is the opportunity for GMTF to leverage the industry leader's global presence and networks. This will enable the company to explore new markets and reach a broader customer base, both domestically and internationally. By tapping into new opportunities, GMTF aims to further strengthen its position in the market and establish itself as a prominent player in the global precision measurement industry.As part of the collaboration, GMTF will also benefit from the industry leader's expertise in research and development, enabling them to stay at the forefront of technological advancements in the field of precision measurement. This will ensure that the company remains innovative and continues to deliver state-of-the-art solutions that address the evolving needs of its customers.Overall, the partnership between GMTF and the industry leader holds great promise for the future of the precision measurement industry. With a shared commitment to excellence, innovation, and customer satisfaction, both companies are poised to achieve significant advancements that will benefit businesses across a wide range of industries. The coming together of these two industry players represents a powerful force that will shape the future of precision measurement solutions, setting new standards for quality, performance, and reliability.

How to Set Up a Wedge for Golf: Tips and Techniques

Wedge Setup, a leading global provider of innovative technology solutions, has recently announced the launch of a new product designed to revolutionize the way businesses manage their operations. The company, which has been at the forefront of technology innovation for over a decade, is known for its commitment to delivering cutting-edge solutions that address the evolving needs of modern businesses.The new product, which has been in development for several years, is a comprehensive operations management platform that is designed to streamline and optimize all aspects of a business's operations. From inventory management and supply chain optimization to workforce scheduling and customer relationship management, the platform offers a complete suite of tools that are designed to improve efficiency, reduce costs, and enhance overall productivity."We are thrilled to announce the launch of our new operations management platform," said [spokesperson], CEO of Wedge Setup. "After years of research and development, we believe that we have created a solution that will truly revolutionize the way businesses manage their operations. Our platform is designed to be intuitive, flexible, and scalable, making it suitable for businesses of all sizes and industries."One of the key features of the new platform is its advanced analytics and reporting capabilities, which provide businesses with valuable insights into their operations. By leveraging the power of data analytics, businesses can gain a deeper understanding of their processes and identify areas for improvement. This, in turn, can lead to more informed decision-making and greater overall efficiency.In addition to its powerful analytics and reporting capabilities, the new platform also offers a range of other features designed to improve operations. These include integrated communication tools, real-time tracking and monitoring, and customizable workflow automation. The platform is also fully cloud-based, allowing businesses to access their data and manage their operations from anywhere, at any time."We believe that our new platform will have a significant impact on the way businesses operate," [spokesperson] continued. "By providing a comprehensive suite of tools that are designed to empower businesses to make better decisions and operate more efficiently, we are confident that our platform will be a game-changer for the industry."In addition to the launch of the new operations management platform, Wedge Setup has also announced several strategic partnerships with leading industry players. These partnerships will further enhance the capabilities of the platform and ensure that it remains at the cutting edge of technology."We are committed to ongoing innovation and development," [spokesperson] stated. "By partnering with other industry leaders, we are able to integrate the latest technologies and best practices into our platform, ensuring that it remains a leading solution for businesses."As the business landscape continues to evolve at a rapid pace, the need for robust operations management solutions has never been greater. With the launch of its new platform, Wedge Setup is poised to help businesses around the world meet the challenges of today's competitive environment. By leveraging the power of technology, businesses can gain a competitive edge and position themselves for long-term success.With a proven track record of delivering innovative solutions that drive business growth, Wedge Setup is well-positioned to make a significant impact with its new operations management platform. As businesses continue to seek ways to improve their operations and adapt to the changing market dynamics, the platform offers a compelling solution that is set to redefine the industry. With its powerful features, intuitive design, and commitment to ongoing innovation, the platform is poised to become a go-to solution for businesses looking to optimize their operations and achieve sustainable growth.

Quality Cast Iron Grey Parts for Industrial Use

Cast Iron Grey Parts Factory, a leading manufacturer of cast iron parts, has established itself as a reliable and trusted supplier in the industry. With a commitment to quality, innovation, and customer satisfaction, the company has quickly become a preferred choice for businesses seeking high-quality cast iron components.The factory, located in the heart of (location), is equipped with state-of-the-art technology and machinery, allowing for the production of a wide range of cast iron parts. From automotive components to industrial machinery parts, the factory has the capability to meet the diverse needs of its customers.One of the key strengths of Cast Iron Grey Parts Factory is its team of highly skilled and experienced engineers and technicians. These professionals bring a wealth of knowledge and expertise to the production process, ensuring that each part meets the highest standards of quality and precision.In addition to its manufacturing capabilities, the company also places a strong emphasis on research and development. By staying at the forefront of new technologies and industry trends, Cast Iron Grey Parts Factory is able to continuously innovate and improve its products, maintaining its competitive edge in the market.Customer satisfaction is at the forefront of the company's mission, and it is reflected in every aspect of its operations. From the initial consultation to the final delivery of the products, the team at Cast Iron Grey Parts Factory is dedicated to providing excellent service and support to its customers.The company's commitment to quality and customer satisfaction has earned it a solid reputation in the industry. Customers can rely on Cast Iron Grey Parts Factory for high-quality products, timely delivery, and competitive pricing.As the demand for cast iron parts continues to grow, Cast Iron Grey Parts Factory remains focused on meeting the needs of its customers. The company is dedicated to expanding its product line and capabilities to ensure that it remains a leader in the industry.In an effort to further strengthen its position in the market, Cast Iron Grey Parts Factory has recently implemented a series of efficiency and quality control measures. These initiatives are aimed at streamlining the production process, reducing lead times, and enhancing the overall quality of its products.Furthermore, the company has invested in training and development programs for its employees, ensuring that the team remains at the forefront of industry standards and best practices. By investing in its workforce, Cast Iron Grey Parts Factory is able to maintain its high level of quality and consistency in its manufacturing processes.Looking towards the future, Cast Iron Grey Parts Factory is well-positioned to capitalize on the growing demand for cast iron parts. The company remains committed to its core values of quality, innovation, and customer satisfaction, and is dedicated to maintaining its position as a leading manufacturer in the industry.With its state-of-the-art facilities, experienced team, and unwavering commitment to excellence, Cast Iron Grey Parts Factory is poised for continued success in the industry. Customers can expect nothing less than the highest quality and service from this trusted supplier of cast iron parts.

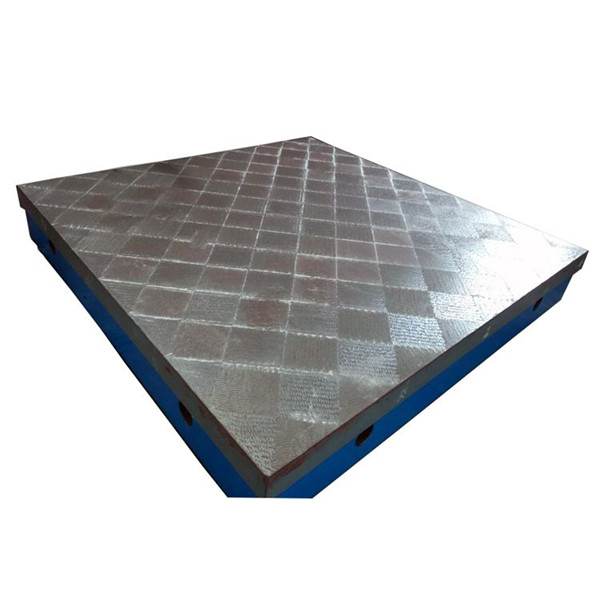

Premium Cast Iron T-Slotted Test Beds for Precision Testing

{Company Name} is proud to introduce its latest innovation in testing equipment - the Cast Iron T-Slotted Test Beds. These test beds are designed to provide a stable and versatile platform for a wide range of testing applications, making them an essential tool for any testing facility.The Cast Iron T-Slotted Test Beds are constructed from high-quality cast iron, providing exceptional durability and stability. The cast iron construction also ensures that the test beds are capable of withstanding heavy loads and intense testing conditions, making them suitable for a variety of testing applications.One of the key features of the Cast Iron T-Slotted Test Beds is their T-slotted design, which allows for easy and secure fixture mounting. This design feature provides users with the flexibility to securely mount a wide range of fixtures and testing equipment, making the test beds suitable for a variety of testing applications. Whether it's tensile testing, compression testing, fatigue testing, or any other form of material testing, the Cast Iron T-Slotted Test Beds are equipped to handle it all.In addition to their T-slotted design, the test beds also feature a precision-machined surface, ensuring flatness and parallelism within a specified tolerance. This level of precision is essential for accurate and reliable testing, making the Cast Iron T-Slotted Test Beds an invaluable tool for any testing facility.Furthermore, the test beds are available in a range of standard sizes, with custom sizes also available upon request. This flexibility allows for the test beds to be tailored to the specific needs of each testing application, ensuring that they can accommodate a wide range of testing requirements.The Cast Iron T-Slotted Test Beds are also designed with ease of use in mind. They are equipped with integrated leveling screws, making it easy to achieve a level and stable testing surface. Additionally, the test beds feature a modular design, allowing for easy expansion and customization as testing needs evolve.At {Company Name}, we understand the importance of reliable and accurate testing equipment. That's why we have carefully engineered the Cast Iron T-Slotted Test Beds to meet the highest standards of quality and performance. With their durable construction, versatile design, and precision-machined surface, the test beds are sure to become a staple in any testing facility.In conclusion, the introduction of the Cast Iron T-Slotted Test Beds represents a significant advancement in testing equipment technology. Their durable construction, versatile design, and precision-machined surface make them an essential tool for any testing facility. With their ability to accommodate a wide range of testing applications and their ease of use, the test beds are set to revolutionize the way testing is conducted. For more information about the Cast Iron T-Slotted Test Beds, please contact {Company Name} or visit our website.

The Benefits of Granite Bases for CMM Systems

Cmm Base Granite, a leading provider of granite products and solutions, has recently introduced a new and innovative approach to granite manufacturing. With a commitment to quality and sustainability, Cmm Base Granite is revolutionizing the industry with its state-of-the-art technologies and environmentally-friendly practices.Cmm Base Granite, headquartered in [location], has been in the granite business for over [number] years. The company prides itself on its ability to provide high-quality granite products for both residential and commercial projects. With a wide range of offerings, including countertops, tiles, slabs, and custom designs, Cmm Base Granite has established itself as a reliable and trusted source for all granite needs.The company's commitment to sustainability is evident in its manufacturing processes. Cmm Base Granite has implemented innovative technologies that minimize waste and reduce energy consumption. By utilizing cutting-edge machinery and equipment, the company is able to maximize the use of raw materials and minimize its environmental impact.One of the key innovations introduced by Cmm Base Granite is the use of advanced CNC machinery in its manufacturing processes. This technology allows for precise and efficient cutting and shaping of granite, resulting in minimal waste and higher productivity. Additionally, Cmm Base Granite has implemented a water recycling system that significantly reduces water consumption during the manufacturing process.In addition to its focus on sustainability, Cmm Base Granite is also committed to delivering the highest quality products to its customers. The company sources its raw materials from reputable quarries and conducts rigorous quality control checks throughout the manufacturing process. This ensures that every product that leaves the Cmm Base Granite facility meets the highest standards of durability, strength, and aesthetic appeal.Furthermore, Cmm Base Granite prides itself on its ability to provide custom solutions for its clients. Whether it's a unique design for a residential kitchen or a large-scale project for a commercial building, the company's team of experienced craftsmen and designers work closely with clients to bring their vision to life. This personalized approach sets Cmm Base Granite apart from its competitors and has earned the company a loyal and satisfied customer base.The recent introduction of Cmm Base Granite's new manufacturing approach is expected to further solidify the company's position as a leader in the industry. With a focus on sustainability, quality, and innovation, Cmm Base Granite is poised to continue delivering exceptional granite products and solutions to its clients."We are very excited about the new approach to manufacturing that we have introduced," said [spokesperson], [title] at Cmm Base Granite. "Our goal has always been to provide our customers with the best products while minimizing our impact on the environment. With our new technologies and processes, we are confident that we can achieve both of these objectives and continue to exceed the expectations of our clients."As Cmm Base Granite continues to innovate and expand its offerings, the company remains dedicated to its core values of quality, sustainability, and customer satisfaction. With a strong foundation built on years of experience and expertise, Cmm Base Granite is well-positioned for sustained success in the ever-evolving granite industry.

Affordable and Effective: Using Floor Tiles as Lapping Plates for Blade and Chisel Flattening

, Marble Tile Lapping Plate, Flattening Blades, Chisels, Soles of Planes, Affordable Solution, FineWoodworking.When it comes to woodworking, having sharp tools is essential. Dull blades, chisels or planes can make your woodworking experience frustrating and can leave you with subpar results. That's why it's important to invest in a good quality lapping plate to keep your tools sharp. However, buying a lapping plate can be expensive, which is why we'd like to suggest an affordable solution - using marble or granite tile as a high-quality lapping plate.Marble and granite tiles are readily available at any home decor or tile store for an affordable price. These tiles are extremely flat and have a smooth surface, providing the perfect platform for sharpening and flattening tools. Plus, they're durable and can withstand wear and tear for years of use. Here's how to use a marble or granite tile as a lapping plate:Step 1: Prepare your tileBefore using the tile as a lapping plate, make sure it's clean and dry. If there are any marks or scratches on the surface, use a fine-grit sandpaper to sand down the surface until it's smooth.Step 2: Add abrasiveApply a small amount of abrasive such as diamond paste or sandpaper. Use a low-grit abrasive to start with, and work your way up to higher grits as needed.Step 3: Start lappingGrab your blade, chisel or plane and start lapping. Hold your tool at a consistent angle and apply pressure as you move it back and forth across the plate. This will create an even, flat surface on your blade, chisel or plane.Step 4: Rinse and repeatContinue lapping until you've reached your desired level of sharpness. Rinse the tool and tile frequently to remove any excess abrasive and check your work often to ensure you're not removing too much metal from the tool.In conclusion, using marble or granite tile as a lapping plate can be a cost-effective and efficient way to keep your woodworking tools sharp and in good shape. It's an affordable alternative to expensive lapping plates and delivers the same results. With these simple steps, you can create a smooth and flat surface on your tools and produce excellent woodworking results. So, the next time you need to sharpen your tools, give this technique a try and experience the benefits.

Newly Developed Cast Iron Lapping Surface Plate for Precision Machining

Title: High-Quality Cast Iron Lapping Surface Plate Revolutionizes Precision ManufacturingIntroduction:Precision manufacturing plays a pivotal role in industries such as aerospace, automotive, and electronics. Achieving exceptional precision requires the use of reliable and accurate tools and equipment. Companies worldwide are constantly pushing boundaries to improve the quality and efficiency of their manufacturing processes. In this regard, a leading manufacturer has introduced their latest innovation - the Cast Iron Lapping Surface Plate.[Company Name], renowned for manufacturing cutting-edge precision tools for several decades, has once again raised the bar with this latest addition to their diverse product range. An integral tool in precision manufacturing, the Cast Iron Lapping Surface Plate promises unparalleled accuracy and reliability.1. Features and Benefits:The Cast Iron Lapping Surface Plate is engineered with meticulous attention to detail to ensure superior performance, making it an indispensable tool for precision manufacturers. It boasts the following remarkable features and benefits:1.1. Superior Build Quality:Constructed using high-quality cast iron, this lapping surface plate is designed for long-lasting durability and stability. Its solid structure guarantees excellent dimensional stability, eliminating any warping or distortion during usage. Such attributes make it an ideal choice for achieving precise measurements consistently.1.2. Flawless Surface Finish:The lapping surface plate is renowned for its perfectly flat and mirror-like surface finish. This characteristic enables manufacturers to achieve accurate measurements and perform meticulous inspections. This feature is crucial in industries where even the smallest deviations can prove costly, such as metrology and semiconductor manufacturing.1.3. Extreme Precision:With precision being the cornerstone of manufacturing excellence, this lapping surface plate is manufactured to industry-leading tolerances. The plate's strict adherence to dimensional accuracy ensures precise and repeatable measurements, aiding manufacturers in achieving optimum quality and reducing wastage.1.4. Versatility:The Cast Iron Lapping Surface Plate caters to a wide range of manufacturing applications. Its versatility allows it to be employed in processes involving precision grinding, lapping, honing, assembly, and layout work. The plate provides an optimal platform for both manual and automated operations, accommodating diverse manufacturing needs.2. Reliable Application Areas:The Cast Iron Lapping Surface Plate has proven to be indispensable in various precision manufacturing domains, including:2.1. Automotive Sector:Automotive manufacturers rely heavily on precision measurements to ensure the seamless and safe functioning of their vehicles. This surface plate provides a stable and reliable platform for the testing and inspection of components, such as engine parts, transmission gears, and brake system elements.2.2. Aerospace Industry:Precision is of paramount importance in the aerospace sector, where safety and performance are critical. The Cast Iron Lapping Surface Plate aids in the accurate fabrication and inspection of intricate aircraft components, promoting error-free assembly and improving overall quality control.2.3. Electronics and Semiconductor Manufacturing:The miniature and complex nature of electronic devices necessitates precision at every stage of production. This lapping surface plate enables manufacturers to maintain the necessary tolerances while fabricating integrated circuits, microchips, and other electronic components.3. Conclusion:In the ever-evolving world of precision manufacturing, the Cast Iron Lapping Surface Plate stands out as a game-changer. Its robust build quality, flawless surface finish, and extreme precision make it an indispensable tool for manufacturers across multiple industries. [Company Name] remains committed to revolutionizing precision manufacturing and sets new benchmarks with their innovative products. As industry demands continue to rise, the Cast Iron Lapping Surface Plate emerges as an indispensable tool in the pursuit of unparalleled accuracy and quality.

Durable and Sturdy Machine Base Made of Cast Iron for Optimal Performance

Casting Iron Machine Base – A Solid Foundation for Precision EngineeringIn the world of precision engineering, having a solid foundation is essential to ensure accuracy, stability, and reliability. This is where Casting Iron Machine Bases come into play. Renowned for their high-quality manufacturing, precision, and durability, these machine bases serve as the backbone for a wide range of industrial applications.As a global leader in the manufacturing of Casting Iron Machine Bases, this company brings together years of expertise and cutting-edge technology to deliver exceptional products that meet the highest industry standards. With a strong commitment to innovation and customer satisfaction, they have earned a stellar reputation in the market.The casting process used to create these machine bases involves pouring molten iron into a mold, allowing it to solidify, and then carefully machining the resulting piece to achieve the desired specifications. This intricate process ensures that each machine base is uniform, structurally sound, and consistent in quality.Precision is of utmost importance in precision engineering, and Casting Iron Machine Bases excel in this aspect. Their inherent stability and vibration-dampening properties make them ideal for applications that require high levels of accuracy. With minimal deflection, these machine bases provide a reliable and robust platform for various industrial processes, including milling, grinding, turning, and many others.Additionally, the superior dampening characteristics of Casting Iron Machine Bases absorb the vibrations generated during machining operations, preventing any negative impact on the final product's quality. This plays a crucial role in industries that demand exceptional surface finishes, dimensional accuracy, and tight tolerances.The versatile nature of Casting Iron Machine Bases allows them to be customized to fit specific requirements. Manufacturers can choose from a wide range of sizes, shapes, and configurations to suit their unique production needs. This flexibility enables these machine bases to be seamlessly integrated into existing production lines or be the foundation for new machining setups.Furthermore, Casting Iron Machine Bases exhibit excellent resistance to wear, corrosion, and temperature fluctuations. This ensures their longevity and reliability even in harsh industrial environments. The exceptional durability of these machine bases minimizes the need for frequent replacements, reducing downtime and maximizing productivity for manufacturers.In addition to their exceptional physical properties, the company behind Casting Iron Machine Bases places great emphasis on environmental responsibility. They are committed to adopting sustainable practices throughout their manufacturing processes, ensuring minimal impact on the environment. By incorporating greener technologies and materials, they constantly strive to innovate and reduce their carbon footprint.With a strong distribution network, the company ensures that customers worldwide have easy access to their high-quality Casting Iron Machine Bases. Their dedicated team of experts offers comprehensive technical support and guidance to assist customers in selecting the right machine base for their specific application. From initial consultation to after-sales service, the company is a trusted partner in providing tailored solutions that meet and exceed customer expectations.The success of Casting Iron Machine Bases lies not only in their exceptional quality but also in the trust and satisfaction of their customers. With an unwavering commitment to innovation, precision, and customer-centricity, this company continues to push the boundaries of what is possible in precision engineering. Whether it's in aerospace, automotive, medical, or any other industry that demands precision and reliability, Casting Iron Machine Bases are the epitome of a solid foundation for success.

High-Quality Black Granite Surface Plate on Steel Base Available for Purchase

: What They Are and Why You Need OneIf you're in the market for a new measuring tool, you may have come across black granite surface plates. But what exactly are they, and why do you need one? In this blog, we'll explore the general specifications of black granite surface plates and their benefits.Black granite surface plates are essentially a flat, polished slab of high-quality black granite that's used for precise measuring. They're incredibly durable, non-corrosive, and don't scratch easily, making them ideal for use in harsh environments. Plus, black granite is an excellent thermal conductor, which means it won't expand or contract with temperature changes.General SpecificationsMost black granite surface plates are manufactured to stringent standards to ensure their high level of accuracy. The plates come in various sizes, from small 12-inch squares to massive slabs measuring several feet in length. Some of the general specifications you'll find with these plates include:- Flatness: Typically, black granite surface plates are manufactured to a grade AA flatness tolerance level, which means they're incredibly flat to within 0.0001" or better.- Surface Finish: The plates' surfaces are typically lapped, which is a process that ensures maximum flatness and roughness control. They're polished to a smooth surface finish with a mirror-like appearance.- Stability: Black granite surface plates sit on sturdy steel or cast iron bases that provide stability during measuring. Some of these bases feature leveling screws that allow for precise adjustment of the plate's height.- Weight: The weight of these plates varies depending on the size, with some of the larger models weighing several hundred pounds. This weight adds to their stability and prevents them from shifting during measurements.BenefitsInvesting in a black granite surface plate can bring numerous benefits to your business, especially if you work in a field that requires precise measuring. Here are some of the benefits of using these plates:- Durability: Black granite is one of the most durable materials available, which means these plates can last for decades with proper care and maintenance.- Corrosion Resistant: Black granite doesn't corrode or rust, making it an ideal material for use in harsh environments like factories or machine shops.- Reduced Wear and Tear: The smooth surface of the plates reduces wear and tear on measuring tools like micrometers, calipers, or dial gauges.- Precision: The level of flatness and surface finish provided by black granite surface plates ensures that measurements are highly precise.- Thermal Stability: Black granite is an excellent thermal conductor, meaning it won't expand or contract with temperature changes. This feature ensures that your measurements remain accurate.ConclusionBlack granite surface plates are a reliable and accurate measuring tool suitable for use in various industries. They're durable, corrosion-resistant, and provide precise measurements that can help improve your productivity and quality control. If you're looking for a highly stable, flat, and accurate surface to measure items, you need to invest in a black granite surface plate.

Shop Online Today for Affordable and High-Quality Measuring Tools with Next Day Delivery Available in the UK.

Granite Tools for Measuring: The Perfect Partner for Accurate EngineeringMeasuring tools are an essential element in the world of engineering. Without them, it would be impossible to accurately assess the dimensions, angles, and other aspects that are fundamental to the creation of precise and reliable products. Among the various options available in the market, Granite tools for measuring stand out as a great alternative due to their outstanding properties and benefits.Granite measuring tools are made of natural granite material, which is renowned for its exceptional stability, flatness, and consistent density. Granite is a hard stone that does not warp, rust, or wear easily, making it an ideal option for manufacturing measuring tools that require precise and consistent measurements. Moreover, granite tools offer excellent vibration-dampening capabilities, reducing the impact of external factors that could interfere with the accuracy of measurements.Granite measuring tools come in different shapes and sizes, depending on the specific application. There are granite squares, straight-edges, surface plates, and angles, among others. Each tool has its own unique features that make it suitable for measuring specific aspects of a component or machine. For instance, a granite surface plate is ideal for measuring flatness, parallelism, and straightness, while a granite angle plate is suitable for checking the squareness of a workpiece or machine parts.Granite measuring tools are widely used in various industries, including aerospace, automotive, machining, and metrology, among others. These tools are ideal for precision engineering and are commonly used for the calibration and inspection of other measuring instruments. Granite measuring tools are also used in research laboratories, where the accuracy and reliability of the data collected are critical.One of the most significant advantages of granite measuring tools is their long lifespan. Unlike other measuring tools made of aluminum or steel, granite tools can last for decades without losing their accuracy. With proper care and maintenance, these instruments can serve as a reliable partner for engineers and technicians for years to come, providing consistent and dependable measurements.In conclusion, Granite tools for measuring are a great investment for any engineering company or laboratory that aims to achieve precision and accuracy in their work. With their exceptional stability, flatness, and durability, these tools are ideal for measuring critical components and machines. Furthermore, granite measuring tools offer excellent value for money, as they can last for decades without losing their accuracy. So, if you want to ensure that your products meet the highest standards of quality, consider investing in granite measuring tools today.