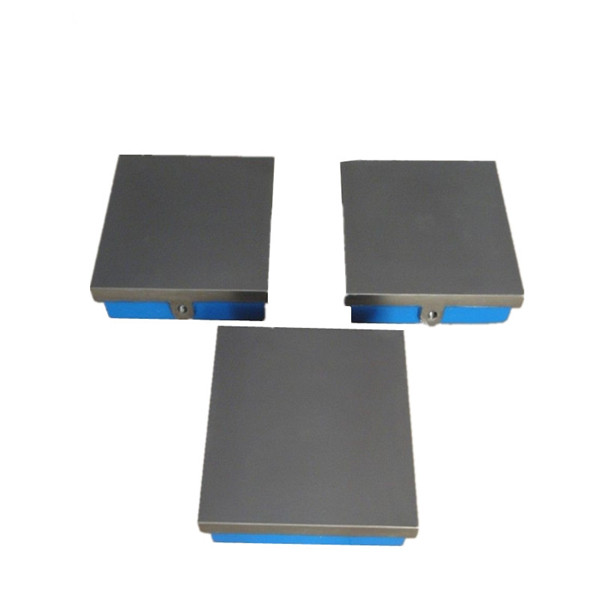

Durable Cast Iron Surface Plates for Industrial Use

By:Admin

The company's Cast Iron Surface Plates are known for their exceptional flatness, surface finish, and overall quality. These plates are essential tools for various applications, including precision measurement, layout, and inspection of components and machinery. [Company Name] offers a wide range of standard sizes and thicknesses, and also has the capability to manufacture custom plates to meet specific customer requirements.

In addition to its standard cast iron surface plates, [Company Name] also provides accessories such as stands, leveling screws, and protective covers to complement its products. These accessories are designed to ensure the proper setup and maintenance of the surface plates, allowing customers to maximize their utility and longevity.

The cast iron used in [Company Name]'s surface plates is sourced from reputable suppliers and undergoes rigorous quality control measures to ensure uniformity and consistency in its properties. This attention to detail, combined with the company's expertise in casting and machining, results in surface plates that are built to last and perform reliably in demanding industrial environments.

One of the key advantages of [Company Name]'s Cast Iron Surface Plates is their stability and resistance to thermal deformation. This makes them ideal for use in temperature-controlled environments and ensures accurate measurements and inspections even under varying conditions.

Furthermore, [Company Name] places a strong emphasis on customer satisfaction and support. The company's knowledgeable sales team works closely with customers to understand their requirements and recommend the most suitable surface plates for their applications. Additionally, [Company Name] provides ongoing technical support and assistance to help customers make the most of their investment in surface plates.

As part of its commitment to quality and continuous improvement, [Company Name] invests in advanced technology and manufacturing processes. The company regularly reviews and updates its production methods to incorporate the latest industry standards and best practices, ensuring that its surface plates consistently meet or exceed customer expectations.

Moving forward, [Company Name] remains dedicated to further enhancing its product offerings and expanding its presence in the global market. The company's ongoing research and development efforts aim to drive innovation and introduce new features that add value to its surface plates, keeping them at the forefront of the industry.

In conclusion, [Company Name] has established itself as a trusted provider of Cast Iron Surface Plates, known for their precision, reliability, and durability. With a focus on quality, customer satisfaction, and innovation, the company continues to set the benchmark for surface plate solutions in a wide range of industrial applications. As [Company Name] looks to the future, its dedication to excellence ensures that customers can rely on its surface plates to meet their evolving needs.

Company News & Blog

Durable Cast Iron Surface Inspection Plate for Quality Control

Industrial Surface Inspection Plate a Breakthrough for Quality ControlIndustrial manufacturers and machine shops face a never-ending challenge to maintain proper quality control for their products. In many cases, the final quality of a product is directly tied to the condition of the tools used in the manufacturing process. One essential tool that is often overlooked is the surface inspection plate, which is a critical component for ensuring the accuracy and precision of machining operations.To address this critical need, a leading provider of industrial technology and equipment has introduced a groundbreaking solution in the form of a cast iron surface inspection plate. This innovative product has been specifically designed to meet the demands of modern manufacturing processes and provides an essential tool for maintaining the highest standards of quality control.The cast iron surface inspection plate, referred to as the Industrial Surface Inspector, is constructed using high-quality cast iron, which is known for its exceptional durability and stability. The surface of the plate is precision-ground and meticulously finished to provide a perfectly flat and smooth surface, ensuring the highest level of accuracy for inspection and measurement tasks.The Industrial Surface Inspector is available in a range of sizes and configurations to accommodate various industrial applications, from small-scale machining operations to large-scale manufacturing facilities. Its robust construction and superior finish make it suitable for use in diverse industrial environments, where it can withstand the rigors of heavy-duty use and provide reliable performance over the long term.In addition to its exceptional durability and precision, the Industrial Surface Inspector is also equipped with a range of features that further enhance its functionality and usability. These include integrated T-slots for securing workpieces and fixtures, as well as provisions for mounting additional accessories such as clamps and supports. The plate also incorporates built-in leveling and anchoring mechanisms to ensure its stability and accuracy during use.One of the key advantages of the Industrial Surface Inspector is its ability to serve as a reference surface for conducting precise measurements and inspections. Its flat and smooth surface provides a reliable reference point for checking the dimensional accuracy and surface finish of machined parts, allowing manufacturers to verify the quality of their products with confidence.Moreover, the Industrial Surface Inspector can also be used for various other critical tasks, such as layout work, assembly operations, and quality assurance checks. Its versatility and precision make it an indispensable tool for ensuring the overall quality and integrity of manufactured products, while also facilitating efficient and accurate manufacturing processes.The introduction of the Industrial Surface Inspector represents a significant advancement in the field of industrial quality control and inspection. By providing manufacturers with a reliable and durable solution for conducting critical measurement and inspection tasks, this innovative product is poised to make a positive impact on the overall quality and consistency of manufactured products.Furthermore, the Industrial Surface Inspector is backed by the expertise and support of its manufacturer, a company that has a long-standing reputation for delivering high-quality industrial technology and equipment. With a commitment to excellence and customer satisfaction, the manufacturer stands behind the performance and reliability of the Industrial Surface Inspector, ensuring that it meets the demanding requirements of modern industrial applications.In conclusion, the introduction of the cast iron surface inspection plate represents a significant step forward for industrial quality control and inspection. With its exceptional durability, precision, and versatility, the Industrial Surface Inspector is set to become an essential tool for manufacturers seeking to maintain the highest standards of quality in their products. Backed by the expertise and support of its manufacturer, this innovative product is poised to make a positive impact on the efficiency and reliability of manufacturing processes across various industries.

Vintage Treadle Sewing Machine with Cast Iron Base - Industrial Age, Antique Home Steam

Title: Unveiling the Sturdy and Timeless Appeal of a Cast Iron Treadle Sewing Machine BaseIntroduction:In the vast landscape of sewing machines, one enduring artifact from the Industrial Age continues to captivate with its unique blend of history, functionality, and craftsmanship. A cast iron treadle sewing machine base, crafted during the New Home Steam era, showcases the beauty and artistry of yesteryear. With its impressive dimensions and unmistakable presence, this vintage treasure stands as a testament to the enduring quality of cast iron machine bases. Join us as we delve into the world of this timeless masterpiece and appreciate its significance in both the past and present.1. The Marvel of a Cast Iron Treadle Sewing Machine Base:The cast iron base of this treadle sewing machine is a brilliant exemplification of the skilled craftsmanship of industrial-age artisans. Its sturdy construction ensures stability and durability, allowing it to withstand the test of time.2. Dimensions and Specifications:Measuring approximately 29" in height, 21" in width, and 13" in depth, this cast iron treadle sewing machine base presents an imposing spectacle. The wheel, with a diameter of approximately 11 1/4", is an integral part of the machine's distinctive appearance. The treadle base, measuring approximately 9 3/4" in height and 13" in width, complements the overall structure.3. Historical Significance:The Industrial Age revolutionized manufacturing processes and introduced new technologies, one of which was the treadle sewing machine. These machines transformed the textile industry by increasing the efficiency and speed of garment production. The cast iron base offered the necessary stability for smooth and continuous operation, earning it a prominent place in the annals of sewing machine history.4. The Alluring Aesthetics of Cast Iron:The casting iron process not only enhanced the strength and durability of the base but also granted it a visual appeal that endures through generations. The texture, feel, and appearance of cast iron evoke a sense of nostalgia, transporting us to an era when industrial marvels were handcrafted with care and precision.5. Versatility and Adaptability:The cast iron base of a treadle sewing machine boasts a seamless compatibility with various tabletop materials. Its design allows for easy attachment and detachment of sewing machine heads, enabling users to switch between sewing methods and projects effortlessly. 6. Collectibility and Antique Value:As the industrial era shifted to more advanced sewing machine technology, these cast iron bases became increasingly rare and sought after as collectibles. Their scarcity has elevated their antique value, making them cherished items for enthusiasts and collectors alike.7. Restoring and Repurposing:While this cast iron treadle sewing machine base may no longer serve its original function, its timeless allure presents an opportunity for restoration and repurposing. With a little innovation and creativity, it can be transformed into a table, desk, or unique piece of home décor that pays homage to the ingenuity of the past.8. Modern Relevance and Demand:In recent times, there has been a resurgence of interest in vintage and antique items. The enduring appeal of this cast iron treadle sewing machine base finds its place in contemporary décor trends, blending nostalgia with modern sensibilities.Conclusion:The cast iron treadle sewing machine base endures as a symbol of a bygone era, where craftsmanship and gradual industrial advancements coexisted. Its steadfastness, attractive aesthetics, and historical significance make it a treasure worth preserving and appreciating. While its original function may have faded away, its versatility allows for new possibilities, breathing life into this vintage artifact. Whether as a cherished collectible or a repurposed accent piece, the cast iron treadle sewing machine base stands as a testament to the indomitable spirit of innovation that shaped the Industrial Age.

T-Slotted Cast Iron Floor Plates: Ideal for Engineering Industry Applications

Cast iron has been used in the manufacturing industry for centuries as it is known for its durability, strength, stability, and resistance to wear and tear. Cast iron is one of the most common materials used in machine bases, worktable beds, and other types of equipment that require rigid and stable support.One great example of the use of cast iron in the manufacturing industry is the JASH Cast Iron T-Slotted Floor Plates. These floor plates are designed and manufactured by JASH, a leading manufacturer and supplier of precision machines and cast iron products. JASH Cast Iron T-Slotted Floor Plates are used in engineering industries as rigid bases for layout, marking, inspection, testing, assembly work, large fixtures, special tooling, and production set-ups.These floor plates are suitable for a wide range of applications in diverse engineering industries, including automotive, aerospace, defense, railway, power generation, and heavy engineering. Their versatility and sturdiness make them the preferred choice for industrial processes that require high accuracy, repeatability, and stability.The JASH Cast Iron T-Slotted Floor Plates are designed to provide a solid, level, and stable base for various industrial applications. The refined cast iron construction provides a high degree of rigidity, vibration damping, and thermal stability. These floor plates are precisely engineered to ensure flatness within ±0.05mm/metre. The T-slots on the surface of the plates help in easy positioning and clamping of workpieces and fixtures.The T-slots on the plates are machined to exacting standards to ensure optimal alignment and smooth motion of workpieces and fixtures. The slots are spaced at regular intervals and are available in different sizes to suit various applications. The T-slots also allow easy attachment and clamping of accessories and tooling, like hold-down bolts, clamps, vices, and chucks.The JASH Cast Iron T-Slotted Floor Plates are available in different sizes, shapes, and configurations to suit various industrial requirements. The plates are available in rectangular, square, and round shapes in sizes ranging from 200mm x 200mm to 4000mm x 4000mm. The plates can be customized to include additional features like holes, pockets, bosses, and pedestals to suit specific production needs.JASH has been a trusted name in the manufacturing and engineering industries for over five decades. The company has a state-of-the-art manufacturing facility equipped with the latest machinery, tools, and systems to produce high-quality and high-performance cast iron products. JASH has a team of highly skilled and experienced engineers, technicians, and support staff who ensure that every product meets the highest international standards of quality and reliability.Apart from Cast Iron T-Slotted Floor Plates, JASH also manufactures other precision machinery and cast iron products like Angle Plates, Box Angle Plates, Granite Surface Plates, and T-Slotted Angle Plates. JASH products are exported to over 30 countries worldwide, and the company has a strong global presence through its network of dealers and distributors.In conclusion, JASH Cast Iron T-Slotted Floor Plates are a reliable and durable solution for industrial processes that require accurate and stable support. Their versatility and precision make them ideal for a wide range of applications in various engineering industries. JASH's commitment to quality, innovation, and customer satisfaction ensures that its products meet the highest standards of performance and reliability. With JASH, you can be assured of getting the best cast iron products that will last for years to come.

Quality Cast Iron Grey Parts for Industrial Use

Cast Iron Grey Parts Factory, a leading manufacturer of cast iron parts, has established itself as a reliable and trusted supplier in the industry. With a commitment to quality, innovation, and customer satisfaction, the company has quickly become a preferred choice for businesses seeking high-quality cast iron components.The factory, located in the heart of (location), is equipped with state-of-the-art technology and machinery, allowing for the production of a wide range of cast iron parts. From automotive components to industrial machinery parts, the factory has the capability to meet the diverse needs of its customers.One of the key strengths of Cast Iron Grey Parts Factory is its team of highly skilled and experienced engineers and technicians. These professionals bring a wealth of knowledge and expertise to the production process, ensuring that each part meets the highest standards of quality and precision.In addition to its manufacturing capabilities, the company also places a strong emphasis on research and development. By staying at the forefront of new technologies and industry trends, Cast Iron Grey Parts Factory is able to continuously innovate and improve its products, maintaining its competitive edge in the market.Customer satisfaction is at the forefront of the company's mission, and it is reflected in every aspect of its operations. From the initial consultation to the final delivery of the products, the team at Cast Iron Grey Parts Factory is dedicated to providing excellent service and support to its customers.The company's commitment to quality and customer satisfaction has earned it a solid reputation in the industry. Customers can rely on Cast Iron Grey Parts Factory for high-quality products, timely delivery, and competitive pricing.As the demand for cast iron parts continues to grow, Cast Iron Grey Parts Factory remains focused on meeting the needs of its customers. The company is dedicated to expanding its product line and capabilities to ensure that it remains a leader in the industry.In an effort to further strengthen its position in the market, Cast Iron Grey Parts Factory has recently implemented a series of efficiency and quality control measures. These initiatives are aimed at streamlining the production process, reducing lead times, and enhancing the overall quality of its products.Furthermore, the company has invested in training and development programs for its employees, ensuring that the team remains at the forefront of industry standards and best practices. By investing in its workforce, Cast Iron Grey Parts Factory is able to maintain its high level of quality and consistency in its manufacturing processes.Looking towards the future, Cast Iron Grey Parts Factory is well-positioned to capitalize on the growing demand for cast iron parts. The company remains committed to its core values of quality, innovation, and customer satisfaction, and is dedicated to maintaining its position as a leading manufacturer in the industry.With its state-of-the-art facilities, experienced team, and unwavering commitment to excellence, Cast Iron Grey Parts Factory is poised for continued success in the industry. Customers can expect nothing less than the highest quality and service from this trusted supplier of cast iron parts.

Durable Cast Iron Surface Plate for Precision Measurement

Surface Plate - Cast Iron, a Reliable Solution for Precision MeasurementIn the world of manufacturing and precision engineering, the need for accurate measurement is paramount. Whether it is for checking the flatness of a component or inspecting the dimensions of a machined part, having the right tools for accurate measurement is essential. This is where the Surface Plate - Cast Iron, produced by a leading company in the industry, comes into play.With a history of providing high-quality metrology equipment, {Company Name} has established itself as a trusted name in the field of precision measurement. The company's Surface Plate - Cast Iron is a key product in its lineup, offering a reliable solution for a wide range of measurement needs.Made from high-quality cast iron, the Surface Plate is designed to provide a stable and flat surface for the accurate measurement of workpieces. The cast iron construction not only ensures durability and longevity but also provides excellent resistance to wear and distortion, making it an ideal choice for demanding manufacturing environments.The Surface Plate - Cast Iron is available in a variety of sizes and configurations to suit different application requirements. Whether it is for small-scale precision work or larger industrial applications, {Company Name} offers a comprehensive range of options to meet the needs of its customers. Additionally, the Surface Plate can be customized according to specific requirements, ensuring that it can meet the unique demands of a wide range of industries.One of the key features of the Surface Plate - Cast Iron is its exceptional flatness and accuracy. Each plate is meticulously hand-scraped to ensure a high degree of flatness, meeting the strictest industry standards for precision measurement. This attention to detail is a testament to {Company Name}'s commitment to providing reliable and accurate metrology equipment for its customers.In addition to its superior flatness, the Surface Plate - Cast Iron is also designed with user convenience in mind. The plates are equipped with a grid of tapped holes, allowing for easy mounting of workpieces and fixtures. This feature not only enhances the versatility of the Surface Plate but also improves the efficiency of measurement tasks, saving time and effort for the operator.Furthermore, each Surface Plate - Cast Iron undergoes rigorous quality control measures to ensure that it meets the highest standards of performance and reliability. This includes a series of precision tests and inspections to verify its flatness, dimensional accuracy, and surface finish. As a result, customers can have full confidence in the quality and accuracy of the Surface Plate, knowing that it has been thoroughly vetted by {Company Name}'s stringent quality assurance processes.The Surface Plate - Cast Iron is an essential tool for a wide range of industries, including automotive, aerospace, defense, and general manufacturing. Its ability to provide a stable and reliable surface for precision measurement makes it an indispensable asset for any organization that values accuracy and quality in its production processes.In conclusion, the Surface Plate - Cast Iron from {Company Name} is a testament to the company's dedication to providing high-quality metrology equipment for its customers. With its exceptional flatness, durability, and user-friendly design, the Surface Plate offers a reliable solution for a wide range of measurement needs. Whether it is for inspecting the flatness of a component or measuring the dimensions of a machined part, customers can rely on the Surface Plate to deliver accurate and consistent results, making it an indispensable tool for precision engineering and manufacturing.Overall, the Surface Plate - Cast Iron is a testament to {Company Name}'s commitment to providing high-quality metrology equipment for its customers, offering a reliable solution for a wide range of measurement needs. With its exceptional flatness, durability, and user-friendly design, the Surface Plate is an indispensable tool for precision engineering and manufacturing.

Durable and Practical Welding Table for Your Welding Projects

The welding industry has reached new heights with the introduction of the innovative Welding Table by a leading manufacturing company. This cutting-edge product is set to revolutionize the way welding projects are carried out, providing a versatile and reliable solution for professionals in the industry.The Welding Table, with its robust design and advanced features, is designed to meet the evolving needs of welding professionals. The table is carefully crafted using high-quality materials to ensure durability and high performance, making it an essential addition to any workshop or industrial setting. Its sturdy construction and precision engineering provide a stable work surface for welding operations, allowing for increased efficiency and accuracy in every project.One of the key highlights of the Welding Table is its modular design, which offers unparalleled flexibility and customization options. This enables users to adapt the table to suit specific project requirements, whether it be for small-scale fabrication work or larger industrial applications. The table's adjustable components and accessories make it a versatile tool for a wide range of welding tasks, offering a level of adaptability that is unmatched by traditional welding surfaces.Furthermore, the Welding Table incorporates innovative technology to enhance user experience and productivity. The inclusion of integrated clamping systems and fixture points allows for secure and precise positioning of workpieces, minimizing the risk of movement during welding. This feature is particularly valuable in complex welding scenarios where precision is crucial for achieving high-quality results.In addition to its functional design, the Welding Table is also equipped with convenient features to streamline the welding process. The table's ergonomic layout and smooth surface make it easy to maneuver workpieces and tools, reducing physical strain on the user and boosting overall efficiency. This thoughtful approach to usability reflects the company's commitment to delivering practical solutions that prioritize the well-being of welding professionals.In line with the company's dedication to quality and innovation, the Welding Table undergoes rigorous testing and quality assurance measures to ensure its reliability and performance. The company's state-of-the-art manufacturing facilities and technical expertise enable them to produce a product that meets the highest industry standards, giving users confidence in the table's long-term durability and functionality.Furthermore, the company's commitment to customer satisfaction extends beyond the product itself, with comprehensive support services and expert guidance available to assist users in maximizing the benefits of the Welding Table. This reflects the company's belief in establishing lasting partnerships with its customers, providing them with the resources and knowledge needed to excel in their welding endeavors.Overall, the introduction of the Welding Table by the esteemed manufacturing company represents a significant advancement in the welding industry. Its innovative design, versatile capabilities, and commitment to user satisfaction position it as a game-changing solution for welding professionals. With this product, the company continues to demonstrate its dedication to driving progress and excellence in the welding sector, setting new benchmarks for quality and performance.

Durable and Reliable Inspection Tables for Granite Materials

Granite Inspection Table Proves to be a Game-changer for Quality Control in Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, ensuring the quality of products is of utmost importance. With the increasing demand for high-quality goods, manufacturers are continually seeking innovative solutions to meet these standards. One such innovative solution that has been making waves in the industry is the granite inspection table.The granite inspection table, a vital tool for quality control purposes, has been gaining popularity in the manufacturing sector due to its precision, durability, and accuracy. These tables are significant in ensuring that all products meet specific quality standards before they are sent out to consumers. The sturdiness and stability of these tables make them ideal for conducting precise measurements and inspections of parts and components in various industries, including automotive, aerospace, electronics, and more.One company that has been at the forefront of providing high-quality granite inspection tables is {Company Name}. Since its establishment, {Company Name} has been committed to delivering top-notch inspection tables to manufacturers worldwide. The company's dedication to quality, innovation, and customer satisfaction has solidified its position as a trusted supplier in the industry.{Company Name} takes pride in its state-of-the-art manufacturing facility, where each granite inspection table is meticulously crafted to meet the exacting standards of its clients. Using advanced machinery and the finest materials, {Company Name} ensures that its inspection tables are not only durable and precise but also tailored to meet the specific needs of its customers.One of the key features that sets {Company Name}'s granite inspection tables apart from the competition is their superior flatness and stability. Made from high-quality granite that is resistant to wear, corrosion, and temperature changes, these tables provide an exceptional surface for accurate measurements and inspections. Furthermore, {Company Name} offers a variety of customization options, including size, shape, and surface finish, to accommodate the unique requirements of different manufacturing processes.The use of granite inspection tables has proven to be instrumental in enhancing the efficiency and accuracy of quality control procedures in the manufacturing industry. Manufacturers who have integrated these tables into their operations have reported significant improvements in their inspection processes, leading to higher product quality and overall customer satisfaction.In addition to providing standard granite inspection tables, {Company Name} also offers ancillary products and accessories to complement the tables, such as precision measurement tools, angle plates, and clamping systems. This comprehensive approach to quality control equipment underscores {Company Name}'s commitment to being a one-stop solution provider for manufacturers seeking to elevate their quality control standards.As the manufacturing industry continues to evolve and demand for superior quality products increases, the role of granite inspection tables in ensuring product quality and consistency is expected to become even more critical. Manufacturers who invest in high-quality inspection tables can gain a competitive edge by streamlining their quality control processes and delivering products that meet or exceed industry standards.In conclusion, the rise of granite inspection tables has transformed the way manufacturers approach quality control, and {Company Name} has been a driving force behind this transformation. With its dedication to excellence and innovation, {Company Name} has established itself as a leading provider of top-of-the-line granite inspection tables, setting a new standard for quality control in the manufacturing industry. As businesses continue to prioritize quality and precision, the demand for these essential tools is only set to grow, and companies like {Company Name} are well-equipped to meet this demand with their cutting-edge solutions.

Top Quality Cast Iron Surface Inspection Plates - Made for Durability and Precision

[Title]: Industry Leader in Cast Iron Surface Inspection Plates Meets Growing Demand with State-of-the-Art Factory Expansion[Subtitle]: Company X Unveils Cutting-Edge Facility to Satisfy Increasing Market Requirements[Date][City, State]In response to the rising demand for cast iron surface inspection plates, industry leader Company X is proud to announce the completion of their state-of-the-art factory expansion project. Boasting ingenious technological solutions and a commitment to quality, the factory will allow the company to meet the growing needs of their customers while establishing itself as the premier provider in the market.Founded in [year], Company X has been at the forefront of the cast iron surface inspection plate industry, serving a diverse customer base ranging from small-scale establishments to multinational corporations. With an unwavering focus on precision and customer satisfaction, the company has earned a reputation for delivering high-quality products that withstand rigorous industrial applications.The impressive factory expansion is a clear reflection of the company's dedication to maintaining its position as an industry leader. Equipped with cutting-edge machinery, the new facility will significantly enhance production capabilities, ensuring consistently superior products for customers worldwide. The factory's increased capacity will allow for larger order fulfillment and shorter turnaround times, providing unparalleled convenience to both existing and prospective clients.One of the key features of the new factory is its advanced technology integration. Company X has invested heavily in state-of-the-art machinery, including computer numerical control (CNC) equipment, robotics, and smart automation systems. These modern advancements optimize production processes, enhance quality control, and improve overall operational efficiency, guaranteeing timely delivery of top-notch cast iron surface inspection plates.However, Company X's commitment to excellence extends beyond technological upgrades. The factory expansion also prioritizes sustainability, aligning with the company's eco-conscious values. Efforts have been made to implement green practices throughout the facility, with initiatives such as energy-efficient lighting, waste reduction programs, and responsible water usage. By reducing its environmental footprint, Company X remains dedicated to protecting the planet while gratifying customer demands.Moreover, the expansion of the factory allows Company X to create a positive impact on the local economy. The increased production capacity has led to the creation of numerous employment opportunities in the region, thereby contributing to job growth and fostering economic development. By supporting the communities in which it operates, the company demonstrates its commitment to being a responsible corporate citizen.Speaking about the factory expansion, Mr. [Name], the CEO of Company X, expressed his enthusiasm for the new chapter in the company's journey. "This expansion represents a significant milestone for Company X and our customers. We are thrilled to bring cutting-edge technology and eco-friendly practices under one roof, thereby solidifying our commitment to innovation and sustainability. With this new facility, we aim to consistently exceed customer expectations while meeting the demands of emerging markets."As industry demands continue to evolve, Company X remains dedicated to staying ahead of the curve. The factory expansion is a testament to the company's unwavering resolve to maintain its position as the industry leader in cast iron surface inspection plates. With its advanced technology, sustainable practices, and a focus on customer satisfaction, Company X is well-positioned to meet the needs of its global clientele and shape the future of the industry.About Company X:[Insert Company X introduction - facts, history, expertise, mission statement, etc.]Note: To make this news article complete, please ensure to add details specific to the Company X's factory expansion, such as its location, size, key technologies used, and any other relevant information.

Quality Granite for Your Master Square Projects

Master Square Granite Announces Expansion Plans in Response to Growing DemandMaster Square Granite, a leading player in the stone and granite industry, has announced plans for a significant expansion to meet the growing demand for their products and services. The company has been gaining attention in the market for its high-quality granite and stone products, and the expansion is seen as a strategic move to capitalize on this momentum.Founded in 2005, Master Square Granite has built a strong reputation for delivering top-notch stone and granite solutions to a diverse range of clients, including homeowners, builders, and architects. The company has established itself as a trusted partner in the industry, known for its commitment to quality, innovation, and customer satisfaction.The recent surge in demand for Master Square Granite's products and services can be attributed to several factors, including the rising construction and renovation activities in the region. As more homeowners and businesses seek to enhance the aesthetics and functionality of their spaces, the demand for premium granite and stone solutions has grown significantly. Additionally, the company's focus on sustainable and environmentally friendly practices has resonated with a growing number of clients who prioritize eco-conscious options.In light of this increasing demand, Master Square Granite has outlined a comprehensive expansion plan that encompasses several key aspects of their operations. One of the primary components of the expansion is the investment in state-of-the-art manufacturing and processing equipment, which will enable the company to enhance its production capabilities and deliver even higher quality products to its customers.Furthermore, the expansion will involve the addition of new facilities and production sites to accommodate the growing volume of orders. By expanding its physical footprint, Master Square Granite aims to streamline its operations and improve efficiency, ultimately leading to shorter lead times and enhanced customer satisfaction. The company's commitment to providing a seamless and hassle-free experience for its clients is evident in this strategic decision to expand its infrastructure.In addition to the expansion of its manufacturing and production capabilities, Master Square Granite also plans to bolster its research and development efforts. With a focus on innovation and continuous improvement, the company aims to stay ahead of the curve in terms of product development and technological advancements in the industry. By investing in R&D, Master Square Granite seeks to introduce new, cutting-edge products that offer unique aesthetic and functional benefits to its customers.The expansion plans also include an emphasis on strengthening the company's distribution network and sales channels. By forging strategic partnerships and collaborations with distributors and retailers, Master Square Granite aims to extend its reach and make its products more accessible to a wider audience. This move aligns with the company's vision of becoming a leading provider of premium stone and granite solutions on a national and international scale.As Master Square Granite gears up for this significant expansion, the company's leadership remains committed to upholding its core values of integrity, excellence, and customer-centricity. The team at Master Square Granite is dedicated to maintaining the highest standards of quality in all aspects of its operations, from sourcing the finest raw materials to delivering exceptional customer service. This unwavering dedication to excellence has been a key driver of the company's success thus far and will undoubtedly continue to propel it forward as it embarks on this new phase of expansion.In conclusion, Master Square Granite's expansion plans mark a significant milestone in the company's journey to solidify its position as a leading player in the stone and granite industry. With a focus on enhancing its production capabilities, driving innovation, and expanding its market presence, Master Square Granite is poised to meet the growing demand for its products and services while maintaining its unwavering commitment to quality and customer satisfaction. The company's expansion is a testament to its resilience, adaptability, and long-term vision, and it is sure to herald a new era of growth and success for Master Square Granite.

Quality Cast Iron Measuring Tools Manufacturers

Cast Iron Measuring Tools Manufacturers, a prominent figure in the field of manufacturing precision measuring tools, has been making waves in the industry with its high-quality products and innovative designs. With a strong focus on providing reliable and accurate measuring tools, the company has established itself as a market leader in the manufacturing of cast iron measuring tools.The company is renowned for its wide range of measuring tools, including squares, levels, protractors, and rulers, all made from high-quality cast iron material. The use of cast iron ensures durability and stability, making the tools ideal for a wide range of applications in various industries.In addition to its extensive product line, Cast Iron Measuring Tools Manufacturers also prides itself on its dedication to quality and precision. The company implements strict quality control measures in every step of the manufacturing process, from sourcing the raw materials to the final inspection of the finished products. This commitment to quality has earned the company a solid reputation for reliability and accuracy among its customers.One of the key strengths of Cast Iron Measuring Tools Manufacturers is its focus on innovation and continuous improvement. The company invests heavily in research and development to create new and improved designs that meet the evolving needs of its customers. This dedication to innovation has led to the development of several patented technologies and designs that set the company apart from its competitors.Furthermore, the company's state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, allowing for efficient production processes and the ability to meet the growing demand for its products. Cast Iron Measuring Tools Manufacturers also takes pride in its team of skilled engineers and technicians who are dedicated to delivering precision-engineered products that meet the highest standards.In terms of customer service, Cast Iron Measuring Tools Manufacturers is committed to providing exceptional support to its clients. The company offers personalized consultation and technical assistance to help customers find the best solutions for their measuring needs. Whether it's a custom order or technical advice, the company's team is always available to assist and ensure customer satisfaction.With a strong emphasis on sustainability and environmental responsibility, Cast Iron Measuring Tools Manufacturers also takes measures to minimize its environmental impact. The company implements eco-friendly practices in its manufacturing processes and seeks to reduce waste and emissions wherever possible.Looking ahead, Cast Iron Measuring Tools Manufacturers is poised to continue its success and further solidify its position as a leading manufacturer of cast iron measuring tools. The company is committed to expanding its product range, exploring new markets, and upholding its reputation for quality and innovation.When asked about the company's future plans, a spokesperson for Cast Iron Measuring Tools Manufacturers stated, "We are constantly looking for opportunities to expand our product offerings and reach new customers. Our goal is to remain at the forefront of the industry by delivering innovative and reliable measuring tools that meet the needs of our diverse customer base. We are excited about the future and look forward to continuing our legacy of excellence in manufacturing."In conclusion, Cast Iron Measuring Tools Manufacturers has established itself as a trusted and respected name in the industry, thanks to its commitment to quality, innovation, and customer satisfaction. With its wide range of high-quality measuring tools, dedication to precision, and focus on sustainability, the company is well-positioned for continued success in the years to come.