Durable Cast Iron Base Plate for Various Applications

By:Admin

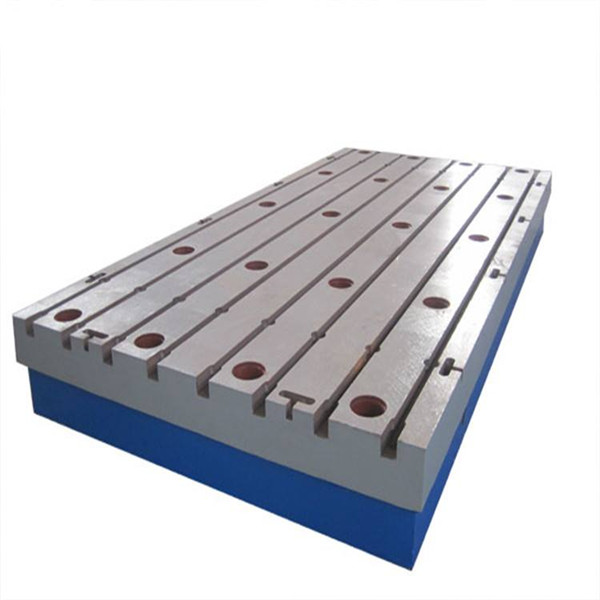

Introducing the Durable and Versatile Cast Iron Base Plate by [Company Name]

[City, Date] – [Company Name], a leading provider of industrial equipment and machinery, is pleased to introduce the new Cast Iron Base Plate to its product line. Designed for durability and versatility, the Cast Iron Base Plate is a valuable addition to any industrial setting.

Constructed from high-quality cast iron, the base plate is designed to provide a stable and reliable foundation for a wide range of equipment and machinery. Whether used for supporting heavy machinery or as a mounting surface for industrial components, the Cast Iron Base Plate is a cost-effective solution for maintaining stability and precision in industrial applications.

The Cast Iron Base Plate is available in various sizes and thicknesses to accommodate different load capacities and workspace requirements. Its solid construction and uniform surface ensure consistent performance and long-term reliability in demanding industrial environments. Furthermore, the base plate's corrosion-resistant properties make it suitable for use in diverse working conditions, including outdoor settings and aggressive chemical environments.

At [Company Name], customer satisfaction and product quality are of the utmost importance. Each Cast Iron Base Plate is meticulously manufactured and inspected to meet the company's high standards for excellence. With a commitment to delivering superior products, [Company Name] aims to provide its customers with the best-in-class solutions for their industrial needs.

The Cast Iron Base Plate is just one of the many innovative products offered by [Company Name]. As a trusted partner in the industrial sector, the company provides a comprehensive range of equipment and machinery, including but not limited to, [list other products and services provided by the company]. With a focus on innovation, reliability, and customer service, [Company Name] has established a strong reputation for delivering quality products that meet the evolving demands of the industry.

In addition to its commitment to product excellence, [Company Name] also emphasizes sustainability and environmental responsibility. The manufacturing processes and materials used in the production of the Cast Iron Base Plate are designed to minimize environmental impact while maximizing product performance and longevity. By prioritizing sustainability, [Company Name] demonstrates its dedication to ethical business practices and the well-being of the planet.

As [Company Name] continues to expand its product offerings and reach new markets, the introduction of the Cast Iron Base Plate reflects the company's ongoing commitment to meeting the diverse needs of its customers. With a focus on quality, durability, and versatility, the base plate is poised to become an essential component in a wide variety of industrial applications.

For more information about the Cast Iron Base Plate and other products offered by [Company Name], please visit [company website] or contact [company contact information].

About [Company Name]:

[Company Name] is a leading provider of industrial equipment and machinery, specializing in [brief description of the company's core products and services]. With a dedication to product excellence, customer satisfaction, and environmental responsibility, the company has earned a reputation for delivering innovative solutions and reliable performance in the industrial sector. For more information, visit [company website] or follow [Company Name] on [social media platforms].

Company News & Blog

Exploring the Versatility and Durability of Cast Iron Machine Tool Bases

Title: Cast Iron Machine Tool Base Revolutionizes Precision ManufacturingIntroduction:In today's competitive manufacturing industry, precision and accuracy are paramount. Enter the cast iron machine tool base, a game-changer that has taken the manufacturing world by storm. By combining heavy-duty cast iron construction with cutting-edge technology, this innovative tool base has revolutionized the way precision components are produced. In this article, we explore the features and capabilities of the cast iron machine tool base and the company that is pioneering its development.I. Background:With advancements in technology and increasing market demands, manufacturing industries have been seeking ways to enhance precision and efficiency in production processes. The cast iron machine tool base, developed by a renowned manufacturing solutions provider, has emerged as a groundbreaking solution.II. Features and Benefits:The cast iron machine tool base boasts several features that set it apart from traditional alternatives. Firstly, the use of cast iron provides exceptional stability and vibration absorption, resulting in enhanced precision. The robust construction ensures minimal distortion even under heavy loads, providing a stable foundation for tooling and machinery.Additionally, the base incorporates state-of-the-art technology that enables precise positioning and accurate machining. Through advanced calibration systems and built-in sensors, the machine tool base can monitor and adjust for any environmental variations, ensuring consistent and high-quality production.Moreover, the base's modular design allows for easy customization and flexibility, providing manufacturers with the versatility to adapt the tool base to their specific needs. This feature ensures that the machine tool base can be integrated seamlessly into existing production lines, minimizing downtime and maximizing productivity.III. Applications:The cast iron machine tool base finds applications across a wide range of industries that require precision manufacturing. From automotive and aerospace to electronics and medical, this tool base provides the foundation necessary to achieve the tight tolerances demanded by these sectors.In the automotive industry, for example, the cast iron machine tool base is used in the production of engine components, transmissions, and chassis parts. Its stability and precision help manufacturers meet stringent quality standards, while also improving overall productivity.Furthermore, in the aerospace industry, where absolute precision is of utmost importance, the machine tool base plays a critical role in the production of aircraft parts and components. By eliminating vibrations and offering accurate positioning, aviation manufacturers can ensure the highest levels of safety and performance.IV. Company Introduction:Behind this groundbreaking invention lies a reputable manufacturing solutions provider, known for its dedication to technological advancements in the industry. With a profound understanding of the challenges faced by modern manufacturers, this company has consistently delivered innovative solutions that enhance efficiency and productivity.Committed to research and development, the company invests heavily in cutting-edge technologies, ensuring that its products remain at the forefront of the market. Backed by a team of experienced engineers and technicians, the company continues to push boundaries, revolutionizing precision manufacturing processes.V. Conclusion:The cast iron machine tool base, developed by this pioneering manufacturing solutions provider, represents a significant advancement in the field of precision manufacturing. Its unique features, such as cast iron construction, advanced technology, and modular design, make it an invaluable asset for industries that demand accuracy and efficiency.As manufacturers strive for higher quality standards and increased productivity, the cast iron machine tool base stands as a testament to the power of innovation. With its ability to provide stability, accuracy, and adaptability, this tool base exemplifies the future of precision manufacturing.

Top Cast Iron Test Bed Plate Suppliers from India - Verified Manufacturers Listed on Exporthub

India, Cast Iron Test Bed Plate Suppliers in India, Cast Iron Plate Manufacturers India, Cast Iron Griddle Suppliers India.Cast iron is widely used in the manufacturing industry, and one of its key applications is in making test bed plates. These plates find use in numerous applications, including machine tool positioning and vibration testing. In India, there are several cast iron test bed plate manufacturers and suppliers, who provide high-quality products to their customers.In this article, we will discuss some top cast iron test bed plate suppliers in India. We will also provide their contact information, catalogs, and other details.1. Bharat Engineering WorksBharat Engineering Works is a leading cast iron test bed plate manufacturer and supplier in India. The company has been in business for over 60 years and specializes in the manufacturing of test bed plates in various sizes and specifications. Their products are known for their durability, strength, and dimensional accuracy. The company also offers customization services to meet specific customer requirements.Contact Information:Website: https://www.bharatenggworks.com/Phone: +91-9873068058Email: [email protected]. Real Test Bed WorksReal Test Bed Works is a well-known cast iron test bed plate supplier in India. They offer a wide range of test bed plates in various sizes and shapes to meet different customer needs. The company has a team of skilled professionals who ensure that their products meet the highest quality standards. They also provide after-sale service to their clients.Contact Information:Website: https://www.realtestbedworks.com/Phone: +91-7387572055Email: [email protected]. Sri Balaji Castings Pvt. Ltd.Sri Balaji Castings Pvt. Ltd. is a leading manufacturer and supplier of cast iron test bed plates in India. The company has over 25 years of experience in the manufacturing of cast iron products and has a state-of-the-art manufacturing facility. Their test bed plates are known for their high strength, durability, and corrosion resistance. They can also customize their products as per customer requirements.Contact Information:Website: https://www.sribalajicastings.com/Phone: +91-8046066123Email: [email protected]. ICES IndiaICES India is a reliable cast iron test bed plate supplier in India. The company specializes in delivering products that meet international quality standards. They offer a diverse range of test bed plates in various sizes and thicknesses. The company also offers timely delivery and competitive prices to their clients.Contact Information:Website: https://www.icesindia.in/Phone: +91-9811374379Email: [email protected]. Foseco India Ltd.Foseco India Ltd. is a leading manufacturer and supplier of cast iron plates in India. They provide high-quality cast iron test bed plates that are used in different industries. Their products are known for their robustness, quality, and durability. The company also offers technical support to its clients.Contact Information:Website: https://www.foseco.com/Phone: +91-20-2720 3009Email: [email protected]:India has a significant number of cast iron test bed plate manufacturers and suppliers who offer high-quality products and excellent customer service. The companies mentioned in this article are some of the best in the industry. They offer a wide range of test bed plates in various sizes and specifications. They also offer customization services and technical support to their clients. So, if you are looking for cast iron test bed plates in India, consider these companies and choose the one that suits your requirements.

Discover the Versatile and Durable Triangular Rulers You Need for Precision Measurements

Headline: Revolutionary Granite Triangular Rulers Set to Redefine Precision MeasurementIntroduction:In today's fast-paced and dynamic world, precision and accuracy are key factors in various industries such as construction, engineering, and design. Recognizing the need for reliable and accurate measuring tools, a renowned company has introduced a groundbreaking product that is set to revolutionize the way professionals measure and create accurate angles. The granite triangular rulers, crafted with utmost precision, provide unparalleled accuracy, durability, and efficiency for a wide range of applications.Paragraph 1:The granite triangular rulers are meticulously designed using cutting-edge technology and manufactured from high-quality granite, ensuring exceptional accuracy and durability. With their unique triangular shape, these rulers offer unparalleled stability when measuring angles, which is crucial for design professionals, architects, woodworkers, and metalworkers alike. The rulers are carefully calibrated to provide precise angle measurements, minimizing errors and enhancing productivity.Paragraph 2:The utilization of granite as the primary material for these rulers not only ensures accuracy but also guarantees their longevity. Unlike traditional rulers made from fragile materials that may warp or deteriorate over time, the granite triangular rulers maintain their accuracy and reliability for years to come. This groundbreaking feature allows professionals to make dependable measurements without the need for constant replacements or recalibrations.Paragraph 3:The innovative design and construction of these rulers also make them ideal for fieldwork. Their robust granite composition enables them to withstand harsh environmental conditions, including extreme temperatures and moisture. This feature ensures accurate measurements regardless of the challenging work environments encountered in the field, making them an indispensable tool for professionals on construction sites or outdoor projects.Paragraph 4:Additionally, the intuitive markings and engravings on the rulers contribute to their user-friendly interface, simplifying measurement tasks. The clear and easy-to-read measurements ensure precise results, reducing human error and ensuring the highest level of precision in every project. Furthermore, the rulers incorporate measurement units commonly used in various industries, such as degrees, radians, and percentages, making them universally compatible and versatile.Paragraph 5:To ensure customer satisfaction and ease of use, the company provides comprehensive support and resources to maximize the potential of these revolutionary rulers. Online tutorials, instructional videos, and user manuals are available to assist in utilizing the exceptional features of the granite triangular rulers effectively. The company's commitment to customer satisfaction is evident in their dedication to providing exceptional after-sales service and assistance.Paragraph 6:Due to the myriad of applications and advantages offered by the granite triangular rulers, they have quickly gained recognition and praise from professionals across industries. Architects appreciate their unmatched accuracy when designing structures, engineers rely on them for precise measurement in construction projects, and designers incorporate them into their artistic creations. The versatility and reliability of the rulers extend their usefulness to a wide range of industries.Conclusion:With the introduction of the granite triangular rulers, precision measurement has reached new heights of accuracy and reliability. Professionals across industries can now trust these durable rulers to provide precise measurements in any environment. As the company strives to meet the evolving needs of its customers, it continues to explore innovative ways to enhance precision measurement tools, setting new industry standards and driving technological advancements.

Efficient Cast Iron Surface Inspection Plate: Exploring Top Features and Benefits

Cast Iron Surface Inspection Plate Finds New Applications in Industry[Company Logo][Company Name], an industry leader in manufacturing and marketing industrial equipment, is proud to announce the release of their latest product, the Cast Iron Surface Inspection Plate. This innovative piece of equipment is designed to revolutionize the inspection process in various industries, improving both efficiency and accuracy.The Cast Iron Surface Inspection Plate is a robust, versatile, and reliable tool that ensures precise and thorough inspection of complex components. It is made from high-quality cast iron, known for its durability, stability, and resistance to wear and tear. The plate's flat and polished surface provides a stable and true reference point for inspection purposes, reducing the risk of errors in measurement.One of the key features of this inspection plate is its compatibility with modern digital technologies. The plate includes strategically placed mounting positions for cameras, sensors, and measurement devices, allowing for the seamless integration of digital inspection systems. This enables real-time monitoring and instant analysis of the inspected parts, leading to faster decision-making and improved overall quality control.The Cast Iron Surface Inspection Plate is not limited to a specific industry or application. Its versatile design makes it suitable for use in various sectors, including automotive, aerospace, energy, and manufacturing. Whether inspecting engine components, turbine blades, precision-machined parts, or any other critical equipment, this tool ensures accurate measurements and inspections, ultimately improving the reliability and safety of the products.Furthermore, the Cast Iron Surface Inspection Plate offers significant benefits in terms of cost reduction and time-saving. Traditional inspection methods often involve multiple setups and elaborate procedures, leading to increased downtime and higher labor costs. However, with the use of this inspection plate, the process becomes streamlined and simplified. It eliminates the need for extensive calibration and repetitive setups, reducing inspection time and increasing productivity.The new inspection plate is also designed with ergonomics in mind. It features an anti-slip coating, ensuring a secure working environment for operators. The lightweight construction allows for easy transportation and maneuverability, contributing to the overall efficiency of the inspection process. Additionally, the plate is resistant to environmental factors such as corrosion or temperature variations, making it suitable for use in different working conditions.[Company Name] has always been at the forefront of innovation in the industrial equipment sector. Their commitment to research and development has resulted in groundbreaking products that meet the evolving needs of various industries. The introduction of the Cast Iron Surface Inspection Plate reinforces their dedication to providing cutting-edge solutions that improve quality control and inspection processes.The company's CEO, [CEO Name], expressed enthusiasm about the new product, stating, "We believe that the Cast Iron Surface Inspection Plate will revolutionize the inspection process in industries worldwide. Its versatility, compatibility with digital technology, and ergonomic design make it a valuable tool for improving efficiency and ensuring accurate measurements. We are confident that this product will meet and exceed our customers' expectations."In conclusion, the introduction of the Cast Iron Surface Inspection Plate marks a significant milestone in the field of industrial equipment. With its robust construction, compatibility with digital technologies, and adaptability to various industries, this inspection plate is set to transform the inspection process, improving efficiency, accuracy, and cost-effectiveness. [Company Name]'s commitment to innovation and customer satisfaction shines through their latest offering, reinforcing their position as a leading provider of industrial equipment.

Top Manufacturers Offer High-Quality Cast Iron Surface Plates for Industrial Use

Title: Leading Cast Iron Surface Plate Factory Revolutionizes Industrial StandardsIntroduction:In a significant development for the manufacturing industry, a renowned cast iron surface plate factory, headquartered in [Company's Location], is making waves with its revolutionary products and commitment to innovation. With a rich history and a strong focus on quality and precision, this factory has established itself as a leading player in the field, catering to a wide range of industries and customers.State-of-the-Art Manufacturing Process:In a bid to maintain its position at the forefront of the industry, this leading cast iron surface plate factory utilizes the latest cutting-edge technology and employs a team of skilled craftsmen who are committed to producing impeccable products. The factory's manufacturing process involves a meticulous combination of modern machinery and traditional techniques, ensuring the highest levels of accuracy, durability, and reliability.Unparalleled Quality Assurance:Quality assurance is at the heart of the factory's operations. The factory continuously invests in research and development, ensuring that its line of cast iron surface plates is not only built to last but also meets the ever-changing demands of the industry. Each plate undergoes rigorous testing and scrutiny, adhering to international standards and certifications to guarantee optimum performance.Furthermore, the factory maintains stringent quality control throughout the production cycle, from the selection of raw materials to the final packaging and delivery. These measures ensure that every plate leaving the factory is flawless, providing customers with a reliable tool that surpasses expectations.Versatile Applications:With a diverse range of offerings, the cast iron surface plates from this factory find applications across various industries. From precision engineering to automotive manufacturing, aerospace, and scientific research, these plates are trusted for their ability to deliver unrivaled accuracy and stability.The factory provides customized solutions to meet the specific needs of different industries, catering to both standard and bespoke plate requirements. This dedication to versatility has earned the factory a reputation as a reliable partner for businesses looking to enhance their efficiency and precision.Environmental Responsibility:Beyond its commitment to superior quality products, the cast iron surface plate factory is also dedicated to minimizing its environmental impact. This includes implementing sustainable practices within its manufacturing process, such as optimizing energy usage, reducing waste production, and responsibly managing resources.Furthermore, the factory demonstrates a commitment to employee welfare and safety, ensuring a healthy work environment while upholding ethical labor practices. By embodying principles of sustainable development, the factory sets an example for the entire industry, inspiring others to follow suit.Expansion and Global Reach:As a testament to its success, the cast iron surface plate factory has expanded its operations domestically and internationally. With strategically located warehouses and distribution centers, the factory efficiently caters to customers around the world, offering timely deliveries and excellent after-sales service.Conclusion:Through its unwavering commitment to quality, innovation, and customer satisfaction, the leading cast iron surface plate factory has emerged as a game-changer in the manufacturing industry. With its cutting-edge technology, stringent quality control processes, and versatile applications, the factory continues to revolutionize industrial standards.Going forward, the factory remains dedicated to pushing boundaries, investing in research and development to develop even more advanced and efficient solutions. By setting a new benchmark for excellence, this factory is poised to lead the industry into a future defined by precision, accuracy, and superior product performance.

Top Manufacturer of Welding Tables

Title: Revolutionizing Welding Industry: Leading Manufacturer Introduces Cutting-Edge Welding TablesIntroduction:In a bid to address the evolving needs of the welding industry, a renowned manufacturer has recently unveiled their latest line of innovative welding tables. These pioneering tables are designed to revolutionize the way welders work, offering enhanced functionalities and exceptional durability. [Company Name] has long been recognized as a frontrunner in the field of welding equipment, and their latest range of tables holds great promise in improving efficiency and productivity for professional welders worldwide.The Role of Welding Tables in the Welding Process:Welding tables play a vital role in ensuring accuracy, stability, and overall safety during the welding process. A high-quality welding table acts as a sturdy foundation, providing a stable platform for the welding material, tools, and workpieces. Traditional tables often lack the required stability, accuracy, and suitable clamping systems, resulting in reduced productivity and reliability. Recognizing these limitations, [Company Name] has set out to develop a range of tables that meets the rigorous demands of professional welders.Cutting-Edge Features:1. Durability and Stability: [Company Name]'s new line of welding tables is forged from high-quality materials, guaranteeing exceptional durability and longevity. These tables are designed to withstand high temperatures, heavy loads, and frequent use, ensuring reliable performance in even the most demanding welding projects. Additionally, the tables feature a stable and level work surface, minimizing the risk of accidents and ensuring precise welding results.2. Modular Design: The innovative modular design of these welding tables enables customization to suit the specific requirements of each welding project. The tables are equipped with a grid pattern, allowing for easy positioning and clamping of workpieces. This flexibility affords welders greater versatility, enabling them to achieve complex welds with ease.3. Enhanced Clamping Systems: [Company Name] understands the importance of a robust clamping system for effective welding. To this end, their tables boast a wide range of customizable and adjustable clamping options, enabling welders to firmly secure diverse workpieces without compromising quality.4. Ergonomics: Welding is a labor-intensive occupation that often involves long hours of physical effort. [Company Name]'s welding tables are designed with ergonomics in mind. The adjustable height feature allows welders to work in a comfortable position, reducing fatigue and increasing productivity.The Impact on the Welding Industry:The introduction of [Company Name]'s advanced welding tables is expected to have a significant impact on the welding industry for several reasons:1. Increased Precision: The tables' sturdy construction and precise design enable welders to achieve accurate and high-quality welds consistently. This enhanced precision will result in cost-savings for welding companies, as less material will be wasted due to rework or repairs.2. Improved Productivity: The modular design and customizable features allow for efficient and streamlined workflow, reducing the time and effort required to set up welding projects. The tables' accessibility and ergonomic design also contribute to increased productivity and reduced downtime.3. Enhanced Safety: The advanced clamping systems and stable work surface provided by [Company Name]'s tables significantly improve safety during the welding process. Workers can focus on their work with peace of mind, knowing that the risk of accidents and injuries has been minimized.Conclusion:With the introduction of their cutting-edge welding tables, [Company Name] has reaffirmed its position as an industry leader in welding equipment. The improved functionalities and durable design of these tables promise to revolutionize the welding industry by maximizing precision, productivity, and safety. As welding professionals embrace these innovative tools, the efficiency and quality of welding projects are expected to reach new heights. [Company Name]'s commitment to advancing the welding industry through innovation continues to raise the bar and set new standards for the market.

Ultimate Guide to Choosing the Best Welding Table for Your Needs" "Expert Tips for Selecting the Perfect Welding Table

Cast Iron Welding Table: The Perfect Solution for Heavy-Duty Welding ProjectsWelding is an essential part of the industrial world. From joining two pieces of metal to repairing heavy machinery, welding plays a crucial role in our lives. However, welding can be dangerous, and safety should be the top priority when performing any welding activity. That's why choosing the right welding equipment is as important as choosing the right technique.One of the most crucial pieces of equipment in welding is the welding table, and Cast Iron Welding Table stands out as one of the top choices in the market.The Cast Iron Welding Table is designed to provide maximum safety, durability, and versatility. The welding table is manufactured using high-quality cast iron material that ensures it can withstand even the toughest welding projects. Cast iron also offers excellent heat resistance, ensuring that the table doesn't warp or buckle under extreme heat, making it an ideal solution for heavy-duty welding projects.Moreover, Cast Iron Welding Tables come in a wide range of sizes, enabling welders to choose the perfect table that suits their needs. From small and portable welding tables to larger tables that can accommodate bigger welding projects, Cast Iron Welding Table has a solution for all welding needs.Additionally, the welding tables are designed with multiple features and accessories that provide maximum convenience, safety, and efficiency. Some of the features and accessories include:- Precision drilled holes: The welding tables are precision-drilled with evenly spaced holes that allow for easy clamping of workpieces. This feature ensures that workpieces are held firmly, providing maximum safety and accuracy during welding.- Slotted design: Some of the Cast Iron Welding Tables come with a slotted design that provides maximum flexibility when clamping workpieces at different angles.- Heat-resistant surface: Cast Iron Welding Tables come with a heat-resistant surface that withstands extreme heat and spatter from welding, ensuring that the table remains clean and safe for continued use.- Adjustable height: Welding tables come in adjustable heights, providing maximum comfort and reduced strain on the welder's back.These features and accessories make Cast Iron Welding Table a perfect solution for heavy-duty welding projects. Whether you're a professional welder or a DIY enthusiast, Cast Iron Welding Table is a reliable and high-quality option for welding activity.About the CompanyThe company behind Cast Iron Welding Table is a leading manufacturer of welding equipment. The company has been in the welding industry for over 20 years, and its focus has always been on designing and manufacturing high-quality and reliable welding equipment.The company prides itself on its commitment to safety, quality, and customer satisfaction. Each product is designed and manufactured with the best materials and advanced techniques, ensuring that their products meet the highest industry standards.The company has a wide range of products that cater to various welding needs, from welding tables to welding machines, welding accessories, and safety equipment. Their products are sold through various channels, including physical stores and online platforms.Moreover, the company offers excellent customer support and after-sales service, ensuring that customers get the best experience with their products. With their reputation for quality products and exceptional customer service, the company has built a loyal customer base that continues to grow.ConclusionWelding can be a dangerous activity, and safety should be a top priority when performing any welding projects. Choosing the right welding equipment is crucial for ensuring maximum safety, efficiency, and convenience. Cast Iron Welding Table is a reliable and high-quality option for heavy-duty welding projects. Designed with the best materials and advanced features, the welding tables provide maximum safety, durability, and versatility, making them a perfect solution for all welding needs.

Stylish Metallic Wedges for Spring Celebrations!

: The Perfect Choice for SpringSpring is the season of blossoming flowers, warmer temperatures, and most importantly, pre-wedding parties. As the wedding season kicks off, it's time to dust off those stylish wedges that have been hiding in the back of your closet. Wedges are perfect for spring as they are comfortable and provide the necessary support to strut with confidence.This year, there's a twist to the usual wedge style – metallic accents. Wedges with metal embellishments like studs, buckles, or straps add an edgy touch to the traditional design, making them perfect for any casual or formal occasion.Not sure where to start your search for the perfect metallic accent wedges? Fret not, for we have listed our five favorite metal-accented wedges that are sure to elevate your outfit and have you walking in style.1. Metallic Flatform Wedges: These wedges add an extra lift to your height without compromising on comfort. The metallic buckle and strap detailing add a subtle glam to your outfit.2. Embossed Metallic Wedges: If you're looking for something unique and eye-catching, these embossed metallic wedges are just what you need. The intricate detailing on the wedge heel and metallic straps make them a perfect choice for any evening event.3. Peep-Toe Metallic Wedges: A pair of peep-toe metallic wedges are perfect for a daytime event. The open-toe design and metallic detailing on the wedge add sophistication to any outfit.4. Metallic Studded Wedges: If you're looking for an edgier look, these studded wedges are perfect. The metallic studs on the wedge add a rocker-chick vibe to the traditional wedge design, making them perfect for a night out with friends.5. Strappy Metallic Wedges: Delicate and feminine, these strappy metallic wedges are perfect for a beach wedding or daytime event. The metallic straps add a pop of shine to the natural surroundings, making them a stylish choice for any outdoor event.In conclusion, metallic-accented wedges are a must-have for any fashion-forward individual looking to add a stylish twist to their spring/summer wardrobe. Whether you're attending a wedding or just heading out for the day, these wedges are sure to elevate your outfit and have heads turning. So, kick up your heels and strut your stuff with confidence in these stylish metallic-accented wedges.

Discover the Innovative 3D Worktable Made from Cast Iron

[Title]: Revolutionary Cast Iron 3D Worktable Unveiled by Innovation-Focused Company[Subtitle]: Company X Introduces Cutting-Edge Worktable to Boost Productivity in the Manufacturing Industry[Date][CITY], [State] - Company X, a renowned pioneer in the field of industrial innovation, has recently unveiled its latest breakthrough: a revolutionary Cast Iron 3D Worktable. This remarkable creation is set to redefine manufacturing processes, elevate productivity, and augment the precision of industrial operations.The Cast Iron 3D Worktable has been meticulously designed to offer manufacturers an unparalleled level of efficiency and accuracy in their operations. Through a combination of state-of-the-art technology and robust construction, this innovative worktable promises to revolutionize the manufacturing industry.This cutting-edge worktable is constructed using high-quality cast iron, celebrated for its durability and stability. The solid iron structure ensures a rigid foundation, allowing for seamless and precise machining operations. The utilization of cast iron guarantees optimal stability and minimizes vibrations, resulting in superior precision during manufacturing processes.While cast iron worktables are not a new concept, Company X brings a unique touch to the table, leveraging its extensive experience in the field. By integrating advanced 3D technology, Company X has succeeded in enhancing the traditional cast iron worktable, making it more versatile and suitable for modern manufacturing demands.The Cast Iron 3D Worktable utilizes a sophisticated numerical control system, enabling it to seamlessly integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This cutting-edge technology facilitates the creation of intricate and complex parts with utmost precision, significantly reducing the margin for error. The worktable's compatibility with CAD/CAM systems grants manufacturers the ability to seamlessly translate virtual designs into tangible products.Additionally, the 3D capabilities of the worktable allow for the creation of prototypes, providing manufacturers with the opportunity to evaluate and refine their designs before initiating full-scale production. This powerful tool aids in identifying potential flaws or necessary improvements, ensuring the end product meets the highest standards of quality and functionality.Company X's commitment to innovation extends beyond the development of the Cast Iron 3D Worktable. With a strong focus on research and development, the company constantly pushes the boundaries of what is achievable within the manufacturing industry. By investing in cutting-edge technologies and recruiting top-tier talent, Company X ensures it remains at the forefront of industrial innovation.Furthermore, Company X recognizes the importance of sustainable practices and environmental responsibility. Not only does the Cast Iron 3D Worktable contribute to increased productivity and efficiency, but its durable construction also ensures its longevity, minimizing waste and reducing the need for frequent replacements. By prioritizing sustainability, Company X sets a prime example in the industry and encourages other manufacturers to follow suit.The introduction of the Cast Iron 3D Worktable marks a significant milestone for Company X and the manufacturing industry as a whole. Through this groundbreaking innovation, manufacturers can expect enhanced accuracy, improved efficiency, and increased productivity. This pioneering worktable empowers companies to unleash their creativity, accelerating the pace of production and ultimately contributing to the advancement of various sectors reliant on manufacturing processes.In conclusion, Company X's Cast Iron 3D Worktable represents a massive leap forward in the realm of industrial innovation. By combining the robustness of cast iron with advanced 3D technology, the worktable delivers unprecedented precision and versatility to manufacturers. The integration of CAD/CAM compatibility and prototyping capabilities ensures manufacturers can achieve exceptional quality and efficiency in their operations. Company X's unwavering commitment to sustainable practices and continuous research and development solidify its position as an industry leader. As the manufacturing industry evolves, Company X stands ready to shape its future with groundbreaking creations like the Cast Iron 3D Worktable.