High-Quality Cast Iron Surface Inspection Plate for Accurate Results

By:Admin

The {} cast iron surface inspection plates are meticulously manufactured to meet the highest industry standards, ensuring accuracy and reliability in all inspection processes. With a flatness tolerance of ±0.002mm for the entire surface, these plates provide a stable and precise platform for measurements and inspections. The cast iron material also offers excellent stability and thermal conductivity, making it an ideal choice for various industrial applications.

In addition to their superior flatness, the {} cast iron surface inspection plates are also finished with a high-quality, wear-resistant coating that provides durability and protection against corrosion. This ensures that the plates maintain their precision and reliability over time, even in harsh working environments. The plates are available in a range of sizes and configurations to suit different inspection requirements, and can also be customized to meet specific customer needs.

The launch of these cast iron surface inspection plates is a significant milestone for {}. As a leading manufacturer of metrology and inspection equipment, we are committed to providing innovative solutions that help our customers improve their processes and achieve superior results. The introduction of these plates is a testament to our dedication to excellence and our ongoing efforts to meet the ever-evolving needs of the industry.

With the unveiling of these cast iron surface inspection plates, {} is poised to set a new standard for quality and performance in the field of metrology. These plates are the result of extensive research, development, and testing, and they have been engineered to deliver unmatched precision and reliability. We are confident that they will make a positive impact on the operations of our customers, enabling them to streamline their inspection processes and enhance the overall quality of their products.

In addition to the launch of these plates, {} remains committed to providing comprehensive support and service to our customers. We offer a range of training and technical assistance programs to help users get the most out of their inspection equipment, and our team of experts is always on hand to provide guidance and advice. With our dedication to customer satisfaction, we aim to build lasting partnerships with our clients and support them in achieving their quality and productivity goals.

As we look to the future, {} is excited to continue pushing the boundaries of innovation and delivering cutting-edge solutions to the industry. We are confident that our new cast iron surface inspection plates will make a significant impact and we are excited to see the positive outcomes that they will enable for our customers. With our unwavering commitment to quality, performance, and customer satisfaction, we are confident that {} will remain a trusted partner for metrology and inspection solutions for years to come.

Company News & Blog

Ultimate Guide to Finding the Best Quality Spare Parts for Granite Machines

Granite Machine Spare Parts: A Leading Company in the Manufacturing IndustryGranite Machine Spare Parts is a leading manufacturer of high-quality granite machine spare parts. Established in 1994, the company has been providing its products to a wide range of customers around the world. With over two decades of experience, the company has developed a reputation for delivering top-quality products that meet the highest industry standards.The company is headquartered in a state-of-the-art facility located in China. This modern facility is equipped with the latest technology to ensure that all production processes are efficient and effective. The company also has a team of highly skilled professionals who work tirelessly to ensure that all products are of the highest quality.At Granite Machine Spare Parts, customers come first. The company is committed to providing exceptional customer service and making sure that customers are completely satisfied with their products. The company's team of sales representatives are highly knowledgeable about the products and can provide expert advice and guidance to customers.The company's product range is vast and includes a variety of machine spare parts, including spindles, bearings, belts, pulleys, and much more. The company's products are designed to meet the specific needs of different customers and are available in various sizes and specifications. The company uses only the highest quality raw materials to ensure that all products meet the highest industry standards.Granite Machine Spare Parts has been at the forefront of innovation in the manufacturing industry. The company invests heavily in research and development to ensure that its products are always cutting-edge and meet the changing needs of its customers. The company's team of engineers is constantly looking for new ways to improve products and manufacturing processes to make them more efficient and cost-effective.The company's commitment to quality is demonstrated by its adherence to strict quality control measures. All products undergo rigorous testing to ensure that they are of the highest quality before being shipped to customers. The company is also ISO 9001 certified, which is a testament to its commitment to quality.Granite Machine Spare Parts also places great emphasis on environmental sustainability. The company employs environmentally friendly manufacturing processes and uses materials that are safe for the environment. The company's commitment to sustainability is one of the many reasons why it has become a leading player in the manufacturing industry.In conclusion, Granite Machine Spare Parts is a leading manufacturer of high-quality granite machine spare parts. With over two decades of experience, the company has developed a reputation for delivering top-quality products that meet the highest industry standards. The company's commitment to quality, innovation, customer service, and sustainability has made it a trusted partner to a wide range of customers around the world. The company's focus on excellence and continuous improvement is sure to keep it at the forefront of the manufacturing industry for many years to come.

Quality Granite for Your Master Square Projects

Master Square Granite Announces Expansion Plans in Response to Growing DemandMaster Square Granite, a leading player in the stone and granite industry, has announced plans for a significant expansion to meet the growing demand for their products and services. The company has been gaining attention in the market for its high-quality granite and stone products, and the expansion is seen as a strategic move to capitalize on this momentum.Founded in 2005, Master Square Granite has built a strong reputation for delivering top-notch stone and granite solutions to a diverse range of clients, including homeowners, builders, and architects. The company has established itself as a trusted partner in the industry, known for its commitment to quality, innovation, and customer satisfaction.The recent surge in demand for Master Square Granite's products and services can be attributed to several factors, including the rising construction and renovation activities in the region. As more homeowners and businesses seek to enhance the aesthetics and functionality of their spaces, the demand for premium granite and stone solutions has grown significantly. Additionally, the company's focus on sustainable and environmentally friendly practices has resonated with a growing number of clients who prioritize eco-conscious options.In light of this increasing demand, Master Square Granite has outlined a comprehensive expansion plan that encompasses several key aspects of their operations. One of the primary components of the expansion is the investment in state-of-the-art manufacturing and processing equipment, which will enable the company to enhance its production capabilities and deliver even higher quality products to its customers.Furthermore, the expansion will involve the addition of new facilities and production sites to accommodate the growing volume of orders. By expanding its physical footprint, Master Square Granite aims to streamline its operations and improve efficiency, ultimately leading to shorter lead times and enhanced customer satisfaction. The company's commitment to providing a seamless and hassle-free experience for its clients is evident in this strategic decision to expand its infrastructure.In addition to the expansion of its manufacturing and production capabilities, Master Square Granite also plans to bolster its research and development efforts. With a focus on innovation and continuous improvement, the company aims to stay ahead of the curve in terms of product development and technological advancements in the industry. By investing in R&D, Master Square Granite seeks to introduce new, cutting-edge products that offer unique aesthetic and functional benefits to its customers.The expansion plans also include an emphasis on strengthening the company's distribution network and sales channels. By forging strategic partnerships and collaborations with distributors and retailers, Master Square Granite aims to extend its reach and make its products more accessible to a wider audience. This move aligns with the company's vision of becoming a leading provider of premium stone and granite solutions on a national and international scale.As Master Square Granite gears up for this significant expansion, the company's leadership remains committed to upholding its core values of integrity, excellence, and customer-centricity. The team at Master Square Granite is dedicated to maintaining the highest standards of quality in all aspects of its operations, from sourcing the finest raw materials to delivering exceptional customer service. This unwavering dedication to excellence has been a key driver of the company's success thus far and will undoubtedly continue to propel it forward as it embarks on this new phase of expansion.In conclusion, Master Square Granite's expansion plans mark a significant milestone in the company's journey to solidify its position as a leading player in the stone and granite industry. With a focus on enhancing its production capabilities, driving innovation, and expanding its market presence, Master Square Granite is poised to meet the growing demand for its products and services while maintaining its unwavering commitment to quality and customer satisfaction. The company's expansion is a testament to its resilience, adaptability, and long-term vision, and it is sure to herald a new era of growth and success for Master Square Granite.

Advanced 3D Welding Tables for Modular Projects

Introducing a Revolutionary New Solution for Welding: 3D Modular Welding TablesWelding is a critical process in the manufacturing industry, and having the right equipment is essential for achieving high-quality results. That's why [Company Name] is proud to introduce a groundbreaking new solution for welding: 3D Modular Welding Tables. These innovative tables are set to revolutionize the way welding is done, offering unparalleled versatility, precision, and efficiency.[Company Name] has been a leader in providing cutting-edge solutions for the welding industry for over a decade. With a focus on innovation and quality, the company has continuously strived to develop products that meet the evolving needs of welders and fabricators. The introduction of 3D Modular Welding Tables is a testament to [Company Name]'s commitment to pushing the boundaries of what's possible in welding technology.The 3D Modular Welding Tables are designed to provide a comprehensive and flexible solution for a wide range of welding applications. Utilizing advanced 3D modeling and precision engineering, these tables offer unmatched accuracy and repeatability, ensuring that every weld is performed with the utmost precision. The modular design allows for easy customization, enabling welders to configure the tables to suit their specific needs and project requirements.One of the key features of the 3D Modular Welding Tables is their adaptability to various welding methods, including MIG, TIG, and Stick welding. This versatility makes these tables suitable for a diverse range of projects, from small-scale fabrication to large-scale industrial processes. Additionally, the tables are equipped with advanced clamping and fixturing systems, providing secure and stable support for workpieces of any size and shape.Moreover, the 3D Modular Welding Tables are constructed using high-quality materials that are built to withstand the rigors of the welding environment. The robust construction ensures durability and longevity, making these tables a wise investment for any welding operation. Furthermore, the tables are designed to be user-friendly, with intuitive controls and ergonomic features that make them easy to operate and maintain.In addition to their practical benefits, the 3D Modular Welding Tables also offer significant advantages in terms of efficiency and productivity. By streamlining the welding process and providing a stable and adaptable work surface, these tables can help welders complete their projects faster and with greater precision. This not only saves time and labor costs but also improves the overall quality of the finished welds.[Company Name] is committed to providing comprehensive support for its customers, and the introduction of the 3D Modular Welding Tables is no exception. In addition to offering high-quality products, the company also provides training and technical assistance to ensure that welders can make the most of their investment. This includes comprehensive instruction on using the tables effectively and efficiently, as well as ongoing support for any maintenance or troubleshooting needs.The introduction of 3D Modular Welding Tables represents a significant milestone for [Company Name] and the welding industry as a whole. With their unmatched precision, versatility, and efficiency, these tables are set to redefine the standards for welding equipment. Whether for small-scale fabrication or large-scale industrial projects, these tables offer a comprehensive solution that cater to the diverse needs of welders and fabricators.In conclusion, the introduction of 3D Modular Welding Tables marks a new era in welding technology, and [Company Name] is proud to be at the forefront of this exciting development. With their advanced features, user-friendly design, and comprehensive support, these tables are poised to become an indispensable tool for welders around the world. Whether for improving the quality of welds or streamlining the welding process, the 3D Modular Welding Tables are a game-changer that is sure to benefit the entire welding industry.

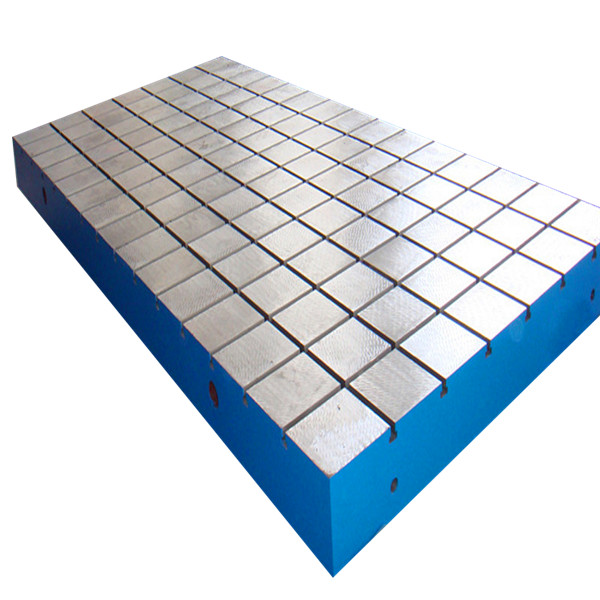

Durable T-Slotted Floor Plate for Your Industrial Needs

Introduction: In recent news, {company name} has announced the launch of their latest product, the Cast Iron T Slotted Floor Plate. As a leading manufacturer in the industry, {company name} is proud to present this innovative and high-quality product, showcasing their commitment to providing top-notch solutions for their clients' needs. With their extensive experience and expertise, {company name} continues to solidify their position as a trusted and reliable partner in the manufacturing sector.The Cast Iron T Slotted Floor Plate:The Cast Iron T Slotted Floor Plate is designed to meet the diverse needs of the manufacturing and industrial sectors. Made from high-quality cast iron, the floor plate is known for its durability and reliability, making it an ideal choice for a wide range of applications. The T-slotted design allows for easy and flexible fixture setups, making it a versatile tool for machining, assembly, and inspection processes.Features and Benefits:One of the key features of the Cast Iron T Slotted Floor Plate is its precision-machined surface, which ensures flatness and accuracy, meeting the stringent requirements of modern manufacturing processes. The T-slots are strategically positioned to provide maximum flexibility for securing workpieces, fixtures, and accessories. Additionally, the cast iron construction offers excellent vibration damping and thermal stability, making it suitable for both heavy-duty and high-precision applications.Moreover, the floor plate is available in various sizes and configurations to accommodate different machining and assembly needs. This versatility allows for seamless integration into existing production environments, enhancing productivity and efficiency. With its robust construction and user-friendly design, the Cast Iron T Slotted Floor Plate is a valuable addition to any manufacturing facility.{company name}’s Commitment to Quality:As a reputable manufacturer, {company name} takes pride in their stringent quality control measures, ensuring that each product meets the highest standards of excellence. The Cast Iron T Slotted Floor Plate is a testament to {company name}’s dedication to delivering superior solutions that drive performance and innovation.With a team of skilled engineers and manufacturing specialists, {company name} utilizes advanced technology and state-of-the-art facilities to produce top-of-the-line products. Their commitment to continuous improvement and customer satisfaction is evident in the reliability and performance of the Cast Iron T Slotted Floor Plate.The {company name} Advantage:{company name} has earned a strong reputation for their unwavering commitment to customer success. Their comprehensive product range, combined with their technical expertise, allows them to serve a diverse clientele across various industries. Whether it's automotive, aerospace, or general manufacturing, {company name} has the capabilities and resources to meet the unique requirements of their customers.Furthermore, {company name} places a strong emphasis on building long-term partnerships, working closely with clients to understand their specific needs and challenges. This customer-centric approach enables {company name} to deliver tailored solutions that address complex manufacturing demands, ensuring optimal performance and efficiency.Conclusion:The launch of the Cast Iron T Slotted Floor Plate further solidifies {company name}’s position as a leading provider of high-quality manufacturing solutions. With a focus on quality, innovation, and customer satisfaction, {company name} continues to set the standard for excellence in the industry. As the manufacturing landscape evolves, {company name} remains committed to delivering cutting-edge products that empower businesses to thrive and succeed.

Durable Cast Iron Surface Inspection Plate for Quality Control

Industrial Surface Inspection Plate a Breakthrough for Quality ControlIndustrial manufacturers and machine shops face a never-ending challenge to maintain proper quality control for their products. In many cases, the final quality of a product is directly tied to the condition of the tools used in the manufacturing process. One essential tool that is often overlooked is the surface inspection plate, which is a critical component for ensuring the accuracy and precision of machining operations.To address this critical need, a leading provider of industrial technology and equipment has introduced a groundbreaking solution in the form of a cast iron surface inspection plate. This innovative product has been specifically designed to meet the demands of modern manufacturing processes and provides an essential tool for maintaining the highest standards of quality control.The cast iron surface inspection plate, referred to as the Industrial Surface Inspector, is constructed using high-quality cast iron, which is known for its exceptional durability and stability. The surface of the plate is precision-ground and meticulously finished to provide a perfectly flat and smooth surface, ensuring the highest level of accuracy for inspection and measurement tasks.The Industrial Surface Inspector is available in a range of sizes and configurations to accommodate various industrial applications, from small-scale machining operations to large-scale manufacturing facilities. Its robust construction and superior finish make it suitable for use in diverse industrial environments, where it can withstand the rigors of heavy-duty use and provide reliable performance over the long term.In addition to its exceptional durability and precision, the Industrial Surface Inspector is also equipped with a range of features that further enhance its functionality and usability. These include integrated T-slots for securing workpieces and fixtures, as well as provisions for mounting additional accessories such as clamps and supports. The plate also incorporates built-in leveling and anchoring mechanisms to ensure its stability and accuracy during use.One of the key advantages of the Industrial Surface Inspector is its ability to serve as a reference surface for conducting precise measurements and inspections. Its flat and smooth surface provides a reliable reference point for checking the dimensional accuracy and surface finish of machined parts, allowing manufacturers to verify the quality of their products with confidence.Moreover, the Industrial Surface Inspector can also be used for various other critical tasks, such as layout work, assembly operations, and quality assurance checks. Its versatility and precision make it an indispensable tool for ensuring the overall quality and integrity of manufactured products, while also facilitating efficient and accurate manufacturing processes.The introduction of the Industrial Surface Inspector represents a significant advancement in the field of industrial quality control and inspection. By providing manufacturers with a reliable and durable solution for conducting critical measurement and inspection tasks, this innovative product is poised to make a positive impact on the overall quality and consistency of manufactured products.Furthermore, the Industrial Surface Inspector is backed by the expertise and support of its manufacturer, a company that has a long-standing reputation for delivering high-quality industrial technology and equipment. With a commitment to excellence and customer satisfaction, the manufacturer stands behind the performance and reliability of the Industrial Surface Inspector, ensuring that it meets the demanding requirements of modern industrial applications.In conclusion, the introduction of the cast iron surface inspection plate represents a significant step forward for industrial quality control and inspection. With its exceptional durability, precision, and versatility, the Industrial Surface Inspector is set to become an essential tool for manufacturers seeking to maintain the highest standards of quality in their products. Backed by the expertise and support of its manufacturer, this innovative product is poised to make a positive impact on the efficiency and reliability of manufacturing processes across various industries.

Guide to Lapping a Granite Surface Plate for Precision Work

Lapping Granite Surface Plate: A Precision Tool for IndustryIn the world of precision manufacturing and measurement, having the right tools is essential. One such tool that is crucial for ensuring accuracy and quality is the lapping granite surface plate. High-quality granite surface plates provide a stable and reliable surface for measuring and inspecting parts, making them a fundamental tool in the manufacturing industry.A granite surface plate is an essential tool in a variety of industries such as aerospace, automotive, and medical device manufacturing, where precision and accuracy are paramount. It provides a flat and stable surface for measuring, laying out, and inspecting workpieces to tight tolerances. In addition, it serves as a reference surface for conducting quality control checks and calibration of instruments.The [Company Name] has been a leading manufacturer of precision granite surface plates for over two decades. They have built a reputation for producing high-quality, reliable, and durable surface plates that meet the stringent demands of the industry. With an unwavering commitment to excellence, [Company Name] has become a trusted supplier to numerous industries, providing them with the precision tools they need to ensure the quality and accuracy of their products.The lapping process is an essential step in the manufacturing of granite surface plates. It involves grinding the surface of the granite to achieve a high degree of flatness and finish. This meticulous process is what sets [Company Name]'s surface plates apart. Their lapping process ensures that the surface plates meet the highest standards for flatness, parallelism, and surface quality, making them an indispensable tool for precision measurement and inspection.The precise and uniform flatness achieved through the lapping process is crucial for accurate measurement and inspection tasks. Granite, with its natural properties of high stability and low thermal expansion, provides an ideal material for surface plates. These properties, combined with the precision lapping process executed by [Company Name], result in surface plates that offer exceptional stability and reliability for measurement and inspection applications.In addition to their standard product offerings, [Company Name] also specializes in custom granite surface plates to meet specific customer requirements. Their team of skilled craftsmen and engineers work closely with customers to design and manufacture surface plates tailored to their unique needs. Whether it's a non-standard size, special features, or specific tolerances, [Company Name] is dedicated to providing custom solutions that meet the exacting demands of their customers.Furthermore, [Company Name] has a comprehensive quality control process in place to ensure that each surface plate meets their stringent quality standards. This includes rigorous inspection and testing at every stage of production, from raw material inspection to the final product. By adhering to strict quality control measures, [Company Name] ensures that their surface plates consistently meet the highest levels of accuracy and reliability.With a commitment to innovation and continuous improvement, [Company Name] is dedicated to staying at the forefront of the industry. They invest in advanced technology and equipment to enhance their manufacturing capabilities and further improve the quality of their products. By staying abreast of the latest developments in precision measurement and manufacturing, [Company Name] continues to provide cutting-edge solutions to their customers.In conclusion, the lapping granite surface plate manufactured by [Company Name] is an indispensable tool for precision measurement and inspection in a wide range of industries. With their unwavering commitment to quality, precision, and customer satisfaction, [Company Name] has established itself as a trusted partner to industries that demand the highest levels of accuracy and reliability. As manufacturing and quality standards continue to evolve, [Company Name] remains dedicated to providing the precision tools that industry professionals rely on to ensure the quality and integrity of their products.

High-Quality Measuring Tools for Precision Engineering

Cast Iron Measuring Tools Factory: Providing Precision in Measuring and GaugingIn the world of manufacturing, precision is an integral component that ensures high-quality products. Every detail counts, and even the slightest deviation can result in costly errors and unsatisfactory outcomes. For this reason, measuring and gauging tools are essential in ensuring accuracy and consistency in production processes.As a leading measuring and gauging tools supplier, our cast iron measuring tools factory provides top-of-the-line equipment that caters to various industrial needs. Our products are made with the highest quality materials and adhering to strict standards to guarantee precision, accuracy, and reliability.One of our flagship products is the cast iron measuring tool. Cast iron, known for its strength and durability, is an excellent material for measuring tools. It is immune to corrosion and wear and tear, making it ideal for demanding manufacturing conditions. At our factory, we use advanced techniques in casting and finishing to ensure that our cast iron measuring tools have the required tolerance levels and impeccable surface finish.Our cast iron measuring tools come in various forms, including squares, straight edges, surface plates, and angle plates. These tools are compatible with other measuring instruments such as micrometers, calipers, and height gauges, making them versatile options for measuring and testing.Another vital measuring and gauging tool in our collection is the granite parallel. Granite is renowned for its stability and hardness; hence, it is an excellent material for precision measuring. With our advanced grinding technology, we produce granite parallels with exceptional parallelism and excellent surface finish. Our granite parallels come in different sizes, from small to large, to cater to various industrial needs.The cast Iron vee shape block is another critical product in our measuring and gauging tool collection. It is a perfect tool for securely holding cylindrical objects in place during the measurement process. Our cast iron vee shape block features robust construction, exceptional surface finish, and precise tolerance levels that guarantee accuracy and reliability.Our granite angle plate is another vital tool for measuring and gauging. It is a versatile instrument that can be used for machining, measuring, and inspection. Our granite angle plate is made from high-quality granite, and it is precisely finished to ensure high accuracy and surface finish.Lastly, our granite measuring and control plate and granite master square are top-of-the-line products that cater to advanced measuring and gauging needs. These tools are ideal for precision measurement tasks, and they feature high accuracy and exceptional surface finish.In conclusion, at our cast iron measuring tools factory, we understand the importance of precision in manufacturing. We strive to provide quality measuring and gauging tools that guarantee accuracy and consistency in production processes. Our products are made with the highest quality materials and adhere to stringent standards to ensure reliability and longevity. Contact us today for all your measuring and gauging tool needs, and we will be glad to offer our expertise and quality products.

High-Quality T-Slotted Cast Iron Plate Supplier for Industrial Needs

[Company Introduction]{Supplier Name} is a leading manufacturer and supplier of cast iron T-slotted plates. With years of experience in the industry, the company has established a strong reputation for providing high-quality products to meet the needs of various industries. Their T-slotted plates are widely used in machine construction, tool making, and precision engineering, and they are known for their durability, precision, and reliability. The company is committed to delivering top-notch products and excellent customer service to their clients, and they continuously strive to innovate and improve their product offerings.[News Content]As the demand for high-quality T-slotted plates continues to rise in various industries, {Supplier Name} has solidified its position as a trusted supplier in the market. The company's dedication to providing top-notch products and exceptional service has made them a preferred choice for businesses looking for reliable and durable T-slotted plates.One of the key factors that set {Supplier Name} apart from its competitors is the superior quality of their cast iron T-slotted plates. The company is known for using high-grade materials and state-of-the-art manufacturing processes to ensure that their products meet the highest standards of quality and performance. This commitment to excellence has earned {Supplier Name} a strong reputation for delivering products that are durable, reliable, and built to last.In addition to their focus on quality, {Supplier Name} also prides itself on offering a wide range of T-slotted plates to meet the diverse needs of their customers. Whether it's a standard size plate or a custom-made solution, the company has the capabilities to deliver products that align with the specific requirements of their clients. This flexibility and customization options have made {Supplier Name} a preferred supplier for businesses in the machine construction, tool making, and precision engineering industries.Furthermore, {Supplier Name} understands the importance of providing excellent customer service. The company's team of experts is dedicated to assisting clients every step of the way, from the initial inquiry to after-sales support. By prioritizing customer satisfaction, {Supplier Name} has developed long-lasting relationships with their clients and continues to be a trusted partner for businesses in need of reliable T-slotted plates.Moreover, {Supplier Name} has always been at the forefront of innovation in the industry. The company continuously invests in research and development to improve their products and manufacturing processes, ensuring that they stay ahead of the curve and meet the evolving needs of their customers. This commitment to innovation has enabled {Supplier Name} to introduce cutting-edge solutions that offer enhanced performance and efficiency to their clients.As a testament to their dedication and hard work, {Supplier Name} has received accolades and recognition for their outstanding products and contributions to the industry. Their commitment to quality, reliability, and innovation has solidified their position as a leading supplier of cast iron T-slotted plates, and they continue to set the benchmark for excellence in the market.In conclusion, {Supplier Name} has proven itself to be a reliable and trusted supplier of high-quality T-slotted plates. With their focus on quality, customization, customer service, and innovation, the company has shown that they are committed to meeting the diverse needs of their clients and delivering products that exceed expectations. As the demand for T-slotted plates continues to grow, {Supplier Name} is well-positioned to remain a top choice for businesses in need of durable and reliable solutions.

High-Quality Steel Wedged Products for Multiple Applications

Steel Wedged Products, a leading manufacturer of cutting-edge industrial tools, is taking the industry by storm with its innovative and high-quality products. With a strong focus on technology and customer satisfaction, the company has established itself as a leader in the market and continues to set new standards in the industry.Steel Wedged Products is dedicated to providing top-of-the-line tools and equipment to its customers, catering to a wide range of industries including construction, automotive, mining, and agriculture. The company offers a diverse range of products including cutting tools, machining tools, and machine parts, all of which are designed to meet the highest standards of quality and performance.A key factor that sets Steel Wedged Products apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development to constantly improve its products and stay ahead of the curve. This commitment to innovation has allowed Steel Wedged Products to introduce cutting-edge technologies and solutions that have revolutionized the industry.One such example of Steel Wedged Products’ innovation is its advanced cutting tools, which are designed to deliver unmatched precision and efficiency. These tools are engineered with state-of-the-art materials and manufacturing techniques, ensuring superior performance and extended durability. Customers can rely on Steel Wedged Products’ cutting tools to deliver outstanding results, even in the most demanding applications.In addition to its innovative products, Steel Wedged Products is also renowned for its exceptional customer service. The company takes great pride in its ability to understand the unique needs of its customers and provide tailored solutions that exceed their expectations. Whether it’s providing expert technical advice or delivering custom-made tools, Steel Wedged Products goes above and beyond to ensure customer satisfaction.Furthermore, Steel Wedged Products is committed to upholding the highest standards of quality and safety. The company’s products undergo rigorous testing and inspection processes to guarantee their reliability and performance. With certifications and accreditations from industry authorities, customers can have full confidence in the quality and safety of Steel Wedged Products’ products.As a testament to its success and leadership in the industry, Steel Wedged Products has established a strong presence in both domestic and international markets. The company’s products are widely distributed and used by leading businesses and organizations around the world, further solidifying its reputation as a trusted and preferred supplier.Looking ahead, Steel Wedged Products is poised for continued growth and success. The company remains dedicated to pushing the boundaries of innovation and delivering unparalleled value to its customers. With a team of skilled professionals and a clear vision for the future, Steel Wedged Products is well positioned to maintain its position as a frontrunner in the industry.In conclusion, Steel Wedged Products stands out as a powerhouse in the industrial tools and equipment sector. With its unwavering commitment to innovation, quality, and customer satisfaction, the company continues to raise the bar and set new benchmarks for excellence. As it forges ahead, Steel Wedged Products will undoubtedly remain a force to be reckoned with in the industry.

Machine Tool Base Price List for Cast Iron

[Company Introduction]With a rich history dating back to more than a century, [Company Name] has established itself as a leading manufacturer of high-quality machine tool bases. Our commitment to precision engineering, innovation, and customer satisfaction has allowed us to build a strong reputation in the industry.We take pride in our state-of-the-art facilities and our team of highly skilled engineers and technicians who work tirelessly to ensure that each product that bears the [Company Name] name meets the highest standards of quality and performance.[Cast Iron Machine Tool Base Pricelist]We are pleased to announce the release of our new pricelist for cast iron machine tool bases. The pricelist features a wide range of bases that cater to the diverse needs of our customers in the manufacturing and machining sectors.Our cast iron machine tool bases are known for their exceptional strength, stability, and vibration dampening properties. They provide a solid foundation for various types of machinery, including lathes, milling machines, grinders, and more. Whether our customers are looking for a standard base design or a custom-made solution, we have the capabilities to meet their requirements.The pricelist includes a variety of base sizes and configurations, ensuring that customers can find the right fit for their specific applications. Furthermore, we offer competitive pricing to ensure that our products deliver excellent value to our customers.In addition to the standard bases listed in the pricelist, we also offer customization services. Our engineering team can work closely with customers to develop bespoke solutions tailored to their unique needs. Whether it's modifying an existing design or creating a completely new base from scratch, we have the expertise to deliver top-quality, customized products.At [Company Name], we understand the importance of delivering products that not only meet but exceed the expectations of our customers. That's why all of our cast iron machine tool bases undergo rigorous quality control checks to ensure that they meet our stringent performance and durability standards.Our commitment to excellence extends beyond just the products we offer. We also take pride in providing exceptional customer service. Our team is dedicated to assisting customers throughout the entire process, from initial inquiries and consultations to after-sales support.As a company that continually invests in research and development, we are always seeking ways to improve our products and processes. This drive for continuous improvement allows us to stay at the forefront of the industry and deliver cutting-edge solutions to our customers.In conclusion, the release of our new cast iron machine tool base pricelist reflects our dedication to providing high-quality products that meet the diverse needs of our customers. Combined with our commitment to exceptional customer service and continuous improvement, we are confident that [Company Name] is well-positioned to serve as a trusted partner for businesses in the manufacturing and machining sectors. We look forward to continuing to provide innovative solutions that help our customers succeed.