High-Quality Cast Iron Casting Parts for Industrial Use

By:Admin

With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, Company ABC has earned a reputation for excellence in the casting industry. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted partner for numerous businesses around the world.

Company ABC's cast iron casting parts are manufactured using the latest technology and the highest quality materials. The company's advanced foundry is equipped with modern machinery and equipment, allowing for the production of complex and intricate cast iron components with precision and efficiency.

The casting process at Company ABC involves the use of mold cavity to create the desired shape, followed by the pouring of molten iron into the mold to form the part. Once the casting has solidified, it undergoes rigorous quality control checks to ensure that it meets the company's strict standards for dimensional accuracy and material integrity.

The versatility of cast iron makes it an ideal material for a wide range of applications, such as automotive components, hydraulic and pneumatic systems, construction equipment, industrial machinery, and more. Company ABC offers a comprehensive range of cast iron casting parts, including housings, brackets, manifolds, and other custom components, in various sizes and specifications to meet the diverse needs of its customers.

Company ABC's team of experienced engineers works closely with clients to understand their specific requirements and provide customized casting solutions that are tailored to their unique needs. Whether it's a prototype development or a large-scale production run, the company is committed to delivering high-quality cast iron casting parts that meet the highest standards of performance and reliability.

In addition to its dedication to quality and innovation, Company ABC is also committed to sustainable and environmentally responsible manufacturing practices. The company utilizes advanced technologies and processes to minimize waste and reduce its environmental footprint, ensuring that its operations are in line with the highest industry standards for sustainability.

With a strong focus on continuous improvement and customer satisfaction, Company ABC has established itself as a leader in the cast iron casting industry. The company's unwavering commitment to excellence, paired with its dedication to innovation and sustainability, sets it apart as a preferred partner for businesses seeking top-quality cast iron casting solutions.

In conclusion, Company ABC continues to set the standard for excellence in the cast iron casting industry. With its advanced manufacturing capabilities, commitment to quality and innovation, and dedication to customer satisfaction, the company remains at the forefront of the industry, providing high-quality casting solutions that meet the diverse needs of its clients.

Company News & Blog

Discover the Advantages of a Cutting-Edge 3D Welding Fixture System

XYZ Company Unveils Revolutionary 3D Welding Fixture System[City, Date] - XYZ Company, a leader in manufacturing and engineering solutions, has recently introduced its groundbreaking 3D Welding Fixture System. This innovative technology is set to revolutionize the welding industry by streamlining processes and improving efficiency.The new 3D Welding Fixture System developed by XYZ Company is a result of years of intensive research and development. It offers a comprehensive solution to the challenges faced by traditional welding fixture systems, making it a game-changer for businesses in the welding industry.Traditional welding fixtures are often time-consuming and require extensive manual adjustments, resulting in a significant loss of productivity. However, XYZ Company's new 3D Welding Fixture System eliminates these drawbacks by utilizing state-of-the-art 3D scanning and modeling technology.The key advantage of XYZ Company's 3D Welding Fixture System is its ability to create precise and accurate fixtures quickly. The system utilizes advanced scanning technology to capture the precise dimensions and contours of the workpiece. This information is then used to generate a virtual 3D model of the fixture, allowing for precise configuration and adjustment without the need for lengthy manual measurements.Furthermore, the fixture can be easily adjusted and modified using the 3D model, reducing the time and effort required for physical adjustments. This feature significantly improves efficiency and reduces downtime, enabling businesses to meet tight deadlines and increase overall productivity.Another notable feature of XYZ Company's 3D Welding Fixture System is its versatility. The system can be used for a wide range of welding applications, including complex and intricate designs. Its adaptive capabilities allow for easy and precise adjustments to accommodate various workpieces, resulting in a flexible solution for diverse welding requirements.The incorporation of advanced automation technology within the 3D Welding Fixture System further enhances its efficiency. The system integrates seamlessly with robotic welding systems, enabling precise alignment and synchronization between the fixture and welding robot. This automation minimizes human errors and optimizes the welding process, ensuring consistent and high-quality welds.The introduction of this innovative 3D Welding Fixture System by XYZ Company marks a significant advancement in welding technology. With its ability to streamline processes, increase productivity, and enhance precision, this system is set to become the new industry standard for welding fixtures.XYZ Company has a long-standing reputation for delivering cutting-edge manufacturing and engineering solutions. With a focus on research and development, the company is committed to pushing boundaries and bringing revolutionary technologies to the marketplace. The introduction of the 3D Welding Fixture System is a testament to XYZ Company's dedication to innovation and its commitment to empowering businesses with advanced tools.As the welding industry continues to evolve, XYZ Company's 3D Welding Fixture System is expected to have a profound impact. Companies in various sectors, including automotive, aerospace, and construction, will undoubtedly benefit from this groundbreaking technology. By improving efficiency, reducing downtime, and enhancing precision, XYZ Company's 3D Welding Fixture System will enable businesses to meet growing demands and stay ahead of the competition.About XYZ Company: XYZ Company is a leading provider of manufacturing and engineering solutions, specializing in delivering cutting-edge technologies to industries worldwide. With a focus on innovation and continuous improvement, XYZ Company has built a reputation for excellence and reliability. By leveraging state-of-the-art technologies, the company aims to empower businesses with advanced tools and solutions to drive success in a rapidly changing market.

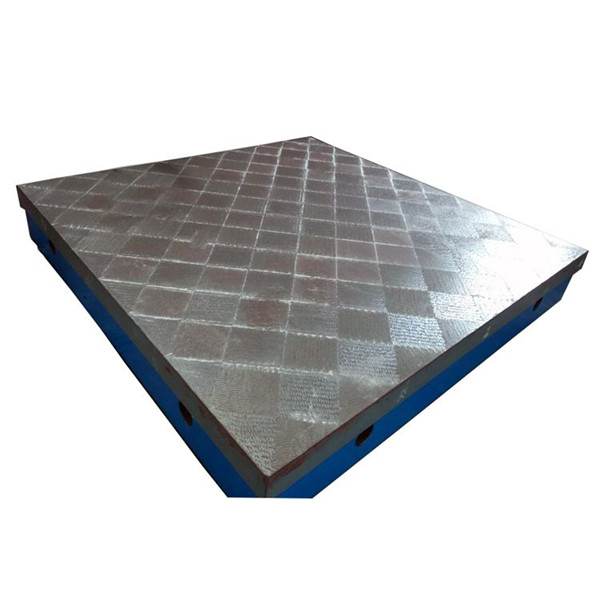

Durable T-Slotted Cast Iron Plate for Industrial Applications

A leading manufacturer in the field of industrial equipment and machinery, [Company Name] is proud to announce the launch of their new product - Cast Iron T-Slotted Plate. The new product is designed to meet the growing demand for high-quality and durable T-slotted plates in the market. With its strong and sturdy construction, the Cast Iron T-Slotted Plate is set to revolutionize the industrial equipment industry.Featuring a robust cast iron construction, the T-slotted plate offers superior strength and durability, making it an ideal choice for various industrial applications. The precision-machined T-slots on the plate provide a secure and reliable mounting solution for a wide range of tools and equipment, allowing for efficient and accurate machining operations. The versatility of the T-slotted plate makes it suitable for use in a variety of industries, including manufacturing, construction, and engineering.[Company Name] has a long-standing reputation for delivering high-quality and innovative products to its customers. With a rich history of manufacturing excellence, the company has established itself as a trusted and reliable supplier of industrial equipment. By leveraging their expertise and experience, [Company Name] has developed the Cast Iron T-Slotted Plate to meet the evolving needs of the industry, providing customers with a reliable and cost-effective solution for their machining and tooling requirements.The Cast Iron T-Slotted Plate is available in a range of standard sizes to accommodate different machining needs. Moreover, [Company Name] also offers custom manufacturing services, ensuring that customers can get T-slotted plates tailored to their specific requirements. This flexibility in product offerings demonstrates the company's commitment to meeting the diverse needs of its customers and providing them with personalized solutions.In addition to the exceptional quality and performance of the T-slotted plate, [Company Name] also prioritizes customer satisfaction by offering competitive pricing and fast delivery. Customers can expect to receive their orders promptly, allowing them to meet project deadlines and keep their operations running smoothly. With a focus on customer-centricity, [Company Name] aims to provide a seamless and hassle-free experience for its customers, from the ordering process to product delivery.The launch of the Cast Iron T-Slotted Plate further solidifies [Company Name]'s position as an industry leader in the industrial equipment market. With a strong commitment to innovation and excellence, the company continues to raise the bar in delivering cutting-edge solutions that empower its customers to achieve their business goals. The T-slotted plate is a testament to [Company Name]'s dedication to driving progress and delivering value to its customers.As the industrial sector evolves and demands for more advanced and efficient equipment, the Cast Iron T-Slotted Plate represents a significant milestone for [Company Name]. The new product embodies the company's unwavering dedication to quality, reliability, and customer satisfaction. It is a testament to their ongoing commitment to meet the evolving needs of the industry and provide customers with the tools they need to succeed in a competitive market.With the launch of the Cast Iron T-Slotted Plate, [Company Name] has once again demonstrated its ability to anticipate market trends and deliver innovative solutions that set the industry standard. As the company continues to expand its product portfolio and enhance its capabilities, customers can expect even more groundbreaking offerings in the future. The Cast Iron T-Slotted Plate is just the beginning of what promises to be an exciting journey of growth and innovation for [Company Name].In conclusion, the launch of the Cast Iron T-Slotted Plate is a significant achievement for [Company Name], and a testament to their commitment to excellence and customer satisfaction. As the industrial sector continues to evolve, [Company Name] remains at the forefront, providing customers with the tools they need to thrive in a dynamic market. The Cast Iron T-Slotted Plate is a game-changer, and a clear indication that [Company Name] is poised to lead the way in delivering innovative and high-quality solutions to its customers.

Shop Online Today for Affordable and High-Quality Measuring Tools with Next Day Delivery Available in the UK.

Granite Tools for Measuring: The Perfect Partner for Accurate EngineeringMeasuring tools are an essential element in the world of engineering. Without them, it would be impossible to accurately assess the dimensions, angles, and other aspects that are fundamental to the creation of precise and reliable products. Among the various options available in the market, Granite tools for measuring stand out as a great alternative due to their outstanding properties and benefits.Granite measuring tools are made of natural granite material, which is renowned for its exceptional stability, flatness, and consistent density. Granite is a hard stone that does not warp, rust, or wear easily, making it an ideal option for manufacturing measuring tools that require precise and consistent measurements. Moreover, granite tools offer excellent vibration-dampening capabilities, reducing the impact of external factors that could interfere with the accuracy of measurements.Granite measuring tools come in different shapes and sizes, depending on the specific application. There are granite squares, straight-edges, surface plates, and angles, among others. Each tool has its own unique features that make it suitable for measuring specific aspects of a component or machine. For instance, a granite surface plate is ideal for measuring flatness, parallelism, and straightness, while a granite angle plate is suitable for checking the squareness of a workpiece or machine parts.Granite measuring tools are widely used in various industries, including aerospace, automotive, machining, and metrology, among others. These tools are ideal for precision engineering and are commonly used for the calibration and inspection of other measuring instruments. Granite measuring tools are also used in research laboratories, where the accuracy and reliability of the data collected are critical.One of the most significant advantages of granite measuring tools is their long lifespan. Unlike other measuring tools made of aluminum or steel, granite tools can last for decades without losing their accuracy. With proper care and maintenance, these instruments can serve as a reliable partner for engineers and technicians for years to come, providing consistent and dependable measurements.In conclusion, Granite tools for measuring are a great investment for any engineering company or laboratory that aims to achieve precision and accuracy in their work. With their exceptional stability, flatness, and durability, these tools are ideal for measuring critical components and machines. Furthermore, granite measuring tools offer excellent value for money, as they can last for decades without losing their accuracy. So, if you want to ensure that your products meet the highest standards of quality, consider investing in granite measuring tools today.

Top Granite Manufacturer Offers Quality Stone Products

Master Square Granite Manufacturer, a leading player in the granite manufacturing industry, has been making waves with its top-quality products and superior customer service. With a strong focus on delivering high-quality granite products to clients around the globe, the company has established itself as a trusted name in the industry. Founded over a decade ago, Master Square Granite Manufacturer has steadily grown to become a prominent player in the granite manufacturing sector. The company's state-of-the-art manufacturing facilities, coupled with a team of skilled professionals, enables them to produce granite products of the highest standards. One of the key factors behind Master Square Granite Manufacturer's success is its commitment to using the latest technology and innovative manufacturing processes. This ensures that the company's products are not only of the highest quality but also at the forefront of industry trends. Furthermore, the company prides itself on its extensive range of granite products, which cater to a wide variety of client needs. Whether it's countertops, flooring, cladding, or customized products, Master Square Granite Manufacturer has the capability to deliver products that meet and exceed customer expectations. In addition to its manufacturing prowess, Master Square Granite Manufacturer places a strong emphasis on customer satisfaction. The company's customer service team is dedicated to providing personalized service to each client, ensuring that their specific requirements are met with the highest level of attention and care. This customer-centric approach has resulted in a loyal and satisfied customer base that continues to grow with each passing year. As Master Square Granite Manufacturer continues to expand its global reach, the company is also mindful of its environmental impact. The company takes pride in its environmentally friendly manufacturing processes and is committed to implementing sustainable practices across all aspects of its operations. This dedication to sustainability has not only positioned the company as an industry leader but also reflects its responsible approach to business. Looking ahead, Master Square Granite Manufacturer has ambitious plans for the future. The company aims to further enhance its production capabilities, broaden its product range, and expand its global footprint. With a strong foundation built on quality, innovation, and customer satisfaction, Master Square Granite Manufacturer is well-positioned to achieve these goals and maintain its status as a top player in the industry. In conclusion, Master Square Granite Manufacturer's rise to prominence in the granite manufacturing industry is a testament to its unwavering commitment to quality, innovation, and customer satisfaction. With a focus on delivering superior products, utilizing cutting-edge technology, and prioritizing customer needs, the company has set itself apart as a trusted and respected industry leader. As it continues to grow and expand, Master Square Granite Manufacturer is poised to make an even greater impact on the global granite manufacturing landscape.

How to Choose the Best Straight Edge for Your Granite Countertops

Granite Fabricator Introduces New Straight Edge for Precision CuttingGranite fabrication is a highly specialized industry that requires precision and attention to detail. For years, professionals have relied on the quality and accuracy of the straight edge tool to ensure the perfect cut. Now, a leading granite fabricator has introduced a new and improved straight edge that is set to revolutionize the industry.The company, which has been in the business for over 20 years, is known for its commitment to innovation and quality. Their new straight edge is a result of extensive research and development, and it promises to deliver unmatched precision and accuracy in granite cutting.Speaking about the new product, the CEO of the company said, "We are excited to introduce our new straight edge to the market. This is a game-changer for the granite fabrication industry, and we believe it will set a new standard for precision cutting."The new straight edge is made from high-quality materials and is designed to withstand the rigors of granite fabrication. It is perfectly straight and has a smooth, non-porous surface that allows for clean and precise cuts. In addition, the straight edge is available in a range of lengths to accommodate different cutting requirements.One of the key features of the new straight edge is its innovative design, which allows for easy and accurate measurements. This ensures that professionals can achieve the perfect cut every time, without any margin for error. The straight edge also comes with a set of precision tools and accessories to further enhance its capabilities.In addition to its exceptional performance, the new straight edge is also designed with user convenience in mind. It is lightweight and easy to handle, minimizing fatigue and strain during long hours of use. Furthermore, it is easy to clean and maintain, ensuring that it remains in top condition for years to come.The company has already received positive feedback from early users of the new straight edge. Many professionals have praised its accuracy and reliability, stating that it has significantly improved their cutting efficiency and the overall quality of their work."We have been using the new straight edge for a few weeks now, and it has completely exceeded our expectations," said one customer. "The precision and accuracy it offers are unmatched, and it has made our work so much easier and more efficient. We highly recommend it to anyone in the granite fabrication industry."The company is also offering comprehensive training and support to professionals who wish to integrate the new straight edge into their work. This includes instructional materials, in-person training sessions, and ongoing technical support to ensure that users are able to maximize the potential of the new tool.With the introduction of the new straight edge, this leading granite fabricator has once again demonstrated its commitment to innovation and quality. The company's dedication to excellence has earned it a strong reputation in the industry, and the new product is poised to further solidify its position as a leading provider of cutting-edge tools and solutions for granite fabrication.In conclusion, the introduction of the new straight edge is set to bring about a significant advancement in the granite fabrication industry. With its unmatched precision, reliability, and user-friendly design, it is expected to become an essential tool for professionals looking to achieve the perfect cut. The company behind the new product continues to set the standard for excellence in the industry, and this latest innovation is a testament to their ongoing commitment to delivering top-quality solutions for granite fabrication.

Discover the Latest Innovation in Welding Tables for Efficient and Precise 3D Welding

Modular 3D Welding Tables Revolutionize the Welding IndustryIn recent years, the welding industry has experienced significant advancements in technology and techniques, greatly improving the efficiency and accuracy of the welding process. One such innovation making waves in the industry is the introduction of modular 3D welding tables. With their unrivaled versatility and precision, these tables have revolutionized the way welders approach their work, offering countless benefits to companies and individuals in the welding field.Developed by a pioneering company at the forefront of welding technology, these modular 3D welding tables have quickly become an indispensable tool for welders worldwide. By combining the company's extensive knowledge of welding with advanced engineering techniques, they have created a product that addresses various challenges faced by welders daily.One of the key features of these modular 3D welding tables is their adaptability to a wide range of welding projects. Traditional welding tables often have fixed dimensions, limiting the types of projects that can be worked on. In contrast, the modular 3D welding tables can be easily customized and configured to meet specific project requirements. This flexibility enables welders to work on projects of different sizes and shapes, ensuring precise and efficient welding regardless of the complexity of the task.The modular design of these welding tables allows for effortless assembly and disassembly, saving valuable time and effort for welders. In addition, the tables are constructed from high-quality materials that are resistant to heat and deformation, ensuring their durability and longevity. Welders can rely on these tables to withstand the demands of their work, employing them for countless projects without fear of premature wear or damage.Moreover, these innovative welding tables are equipped with a highly accurate 3D measuring system, enabling welders to achieve precise alignment and positioning of their workpieces. This feature eliminates the need for additional tools, such as traditional measuring equipment, saving both time and expenses. The tables also incorporate intelligent software that assists in optimizing welding parameters, enhancing workflow efficiency and ensuring consistent quality in the welds.Furthermore, the company behind these tables provides comprehensive training and support for their customers. Recognizing that adapting to new technology can be challenging, especially for seasoned welders accustomed to traditional methods, they offer hands-on training sessions and technical assistance to help users make the most of the tables' capabilities. This commitment to customer success sets them apart from competitors in the industry and establishes a strong relationship between the company and its customers.The impact of these modular 3D welding tables on the welding industry is substantial. Welders can now tackle a wider range of projects with improved efficiency, accuracy, and overall quality. As a result, companies employing these tables have reported increased productivity and reduced costs. The tables' versatility has also paved the way for innovations in welding techniques, inspiring welders to push the boundaries of what can be accomplished.In conclusion, the introduction of modular 3D welding tables has changed the game for welders worldwide. Through their adaptability, precision, durability, and user-friendly features, these tables have revolutionized the welding process. By embracing this innovative technology, companies and individuals in the welding industry can elevate their work to new heights, achieve greater success, and ultimately shape the future of welding.

New Underpinning Wedges: The Latest Innovation in Construction Technology

Underpinning Wedges is a leading manufacturer and supplier of high-quality underpinning products to construction and engineering industries worldwide. With a strong emphasis on innovation and customer satisfaction, Underpinning Wedges has been at the forefront of developing and providing cutting-edge solutions for stabilizing and strengthening structures.The company's commitment to excellence is reflected in its advanced manufacturing processes and stringent quality control measures. Underpinning Wedges produces a wide range of underpinning products, including steel wedges, resin and grout injection systems, and other specialized equipment designed to meet the diverse needs of its global clientele.In addition to its extensive product line, Underpinning Wedges offers comprehensive technical support and consultancy services to assist customers in selecting the most suitable solutions for their specific projects. The company's team of experienced engineers and technicians are dedicated to delivering tailored underpinning solutions that adhere to the highest industry standards and regulations.Recently, Underpinning Wedges has launched a new range of innovative underpinning wedges that are designed to provide enhanced stability and support for a variety of construction and engineering applications. These cutting-edge wedges are manufactured using the latest technologies and materials to ensure maximum strength, durability, and reliability.One of the key features of Underpinning Wedges' new products is their versatility and adaptability to different project requirements. Whether it's for reinforcing foundation structures, stabilizing underground tunnels, or securing bridge supports, these wedges offer a flexible and cost-effective solution for a wide range of challenges in the construction and engineering sectors.Moreover, Underpinning Wedges' commitment to environmental sustainability is evident in the materials and manufacturing processes used for its new range of products. The company prioritizes the use of eco-friendly materials and energy-efficient production methods to minimize its environmental footprint and contribute to a greener and more sustainable future.In line with its mission to deliver excellence in underpinning solutions, Underpinning Wedges has invested significantly in research and development to continually enhance the performance and reliability of its products. The company's state-of-the-art testing facilities and rigorous quality assurance procedures ensure that its products consistently meet or exceed the industry's stringent performance and safety standards.Underpinning Wedges' dedication to customer satisfaction extends beyond the quality of its products, as the company also prioritizes efficient and responsive customer service. From initial inquiries to after-sales support, Underpinning Wedges' team is committed to providing prompt and personalized assistance to ensure that customers receive the guidance and support they need throughout their projects.To further solidify its position as a global leader in the underpinning industry, Underpinning Wedges regularly collaborates with industry partners, conducts training programs, and participates in professional events and exhibitions to share its expertise and insights with the wider construction and engineering community.With its unwavering commitment to innovation, quality, and customer satisfaction, Underpinning Wedges continues to set the benchmark for excellence in the underpinning industry. The company's relentless pursuit of technical advancement and its focus on sustainability underscore its dedication to addressing the evolving needs and challenges of construction and engineering projects around the world. For businesses and organizations seeking reliable and effective underpinning solutions, Underpinning Wedges is poised to be the trusted partner of choice.

High-Quality Machine Parts for Granite Cutting and Fabrication

Granite Machine Parts Expands Product Range to Meet Growing DemandGranite Machine Parts, a leading manufacturer of high-quality machine parts, is pleased to announce the expansion of its product range to meet the growing demand in the manufacturing industry. With a dedication to precision and quality, Granite Machine Parts is committed to providing its customers with top-notch products that deliver exceptional performance and durability.Founded in 1995, {} has been a trusted name in the manufacturing industry for over two decades. The company has built a solid reputation for its expertise in producing a wide range of machine parts, including but not limited to, spindles, chucks, and shafts. {}'s commitment to excellence and innovation has positioned it as a preferred supplier among customers seeking reliable and cost-effective solutions for their machining needs.As the manufacturing industry continues to evolve, so does the demand for advanced and efficient machine parts. In response to this market trend, Granite Machine Parts has expanded its product range to ensure that it can meet the diverse needs of its customers. The company now offers an extended line of machine parts, including custom-made components that are tailored to specific customer requirements. This expansion is a testament to Granite Machine Parts' dedication to staying ahead of the curve and providing cutting-edge solutions to its customers.Granite Machine Parts' comprehensive product range is designed to cater to a wide variety of industries, including automotive, aerospace, medical, and defense. By investing in state-of-the-art manufacturing technologies and employing a team of highly skilled engineers and technicians, {} has the capability to produce machine parts that meet the most stringent quality standards. This ensures that customers can rely on {} to deliver products that consistently exceed their expectations.In addition to its diverse product range, Granite Machine Parts also prides itself on its commitment to excellent customer service. With a team of dedicated professionals who are knowledgeable and responsive, the company strives to provide its customers with a seamless and hassle-free experience from inquiry to delivery. By maintaining open lines of communication and a flexible approach to customer needs, {} has earned the trust and loyalty of its clients, many of whom have been long-term partners.The expansion of Granite Machine Parts' product range comes at a time when the manufacturing industry is experiencing rapid growth and transformation. As companies seek to optimize their production processes and enhance their competitiveness, the demand for reliable and high-performance machine parts is on the rise. By offering an extended line of products that are engineered to deliver exceptional performance and longevity, {} is well-positioned to play a vital role in supporting the evolving needs of the industry.Looking ahead, Granite Machine Parts is committed to continuing its tradition of excellence and innovation. The company is dedicated to staying at the forefront of technological advancements and market developments, ensuring that it can continue to provide its customers with the most advanced and reliable machine parts. With a strong emphasis on quality, precision, and customer satisfaction, Granite Machine Parts is poised to expand its footprint in the global manufacturing industry and solidify its position as a trusted partner for businesses seeking top-tier machine parts.In conclusion, the expansion of Granite Machine Parts' product range is a testament to the company's commitment to meeting the evolving needs of the manufacturing industry. With a focus on quality, precision, and customer satisfaction, {} is well-equipped to provide its customers with the advanced and reliable machine parts they need to drive their businesses forward. As the industry continues to grow and evolve, Granite Machine Parts is poised to play a vital role in supporting this transformation and leading the way in delivering cutting-edge solutions to its customers.

Ultimate Guide to Granite Measuring Tool Prices: Your Complete Pricing Information

In recent years, the demand for high-quality measuring tools has increased significantly, particularly in industries that require precision measurements, such as metalworking, woodworking, and engineering. As such, many companies have started to produce and sell measuring tools made from different materials, including granite.As one of the leading manufacturers of granite measuring tools, the company behind the new pricelist has been providing high-quality measuring equipment to professionals for more than a decade. The company has a long-standing reputation in the industry for producing measuring tools that are accurate, durable, and reliable.The new pricelist offers a comprehensive range of granite measuring tools with different sizes, shapes, and features, making it easy for professionals to find the right measuring tool for their needs. The company offers measuring tools such as granite surface plates, straight edges, squareness, and parallels. Each of these tools is carefully designed and engineered to ensure the highest level of accuracy, allowing professionals to achieve precise measurements with ease.One of the key advantages of granite measuring tools is their resistance to wear and tear. Unlike other measuring tools made from plastic or other materials, granite measuring tools can withstand heavy usage without showing any signs of wear. This is particularly important for professionals who rely on their measuring tools to perform their jobs effectively and efficiently.Another advantage of granite measuring tools is their ability to maintain their accuracy over time. Granite is a dense and stable material that is resistant to changes in temperature and humidity, making it an ideal material for producing measuring tools. The pricelist offers customers a variety of granite measuring tools that are calibrated using sophisticated measuring instruments, ensuring that the tools are accurate and meet industry standards.One of the unique offerings of the company is their customization services. Customers can request custom measuring tools that are designed and built to their specific requirements. This personalized service allows professionals to get the tools they need to perform their jobs effectively, without compromising on quality or accuracy. The company has a team of skilled engineers and technicians who work closely with customers to develop customized measuring tools that meet their exact specifications.To ensure customer satisfaction, the company provides a warranty for all its granite measuring tools, which covers defects in material and workmanship. This warranty assures customers that they are purchasing high-quality measuring tools that will last for many years.In conclusion, the new pricelist for granite measuring tools offers a comprehensive range of high-quality measuring equipment designed to meet the unique needs of professionals in various industries. The company behind the pricelist has a long-standing reputation in the industry for producing accurate, durable, and reliable measuring tools. The company’s commitment to quality is evident in its calibration process, customization services, and warranty. With the new pricelist, professionals can easily find the right measuring tool for their needs, ensuring that they can perform their jobs effectively and efficiently.

Affordable and Effective: Using Floor Tiles as Lapping Plates for Blade and Chisel Flattening

, Marble Tile Lapping Plate, Flattening Blades, Chisels, Soles of Planes, Affordable Solution, FineWoodworking.When it comes to woodworking, having sharp tools is essential. Dull blades, chisels or planes can make your woodworking experience frustrating and can leave you with subpar results. That's why it's important to invest in a good quality lapping plate to keep your tools sharp. However, buying a lapping plate can be expensive, which is why we'd like to suggest an affordable solution - using marble or granite tile as a high-quality lapping plate.Marble and granite tiles are readily available at any home decor or tile store for an affordable price. These tiles are extremely flat and have a smooth surface, providing the perfect platform for sharpening and flattening tools. Plus, they're durable and can withstand wear and tear for years of use. Here's how to use a marble or granite tile as a lapping plate:Step 1: Prepare your tileBefore using the tile as a lapping plate, make sure it's clean and dry. If there are any marks or scratches on the surface, use a fine-grit sandpaper to sand down the surface until it's smooth.Step 2: Add abrasiveApply a small amount of abrasive such as diamond paste or sandpaper. Use a low-grit abrasive to start with, and work your way up to higher grits as needed.Step 3: Start lappingGrab your blade, chisel or plane and start lapping. Hold your tool at a consistent angle and apply pressure as you move it back and forth across the plate. This will create an even, flat surface on your blade, chisel or plane.Step 4: Rinse and repeatContinue lapping until you've reached your desired level of sharpness. Rinse the tool and tile frequently to remove any excess abrasive and check your work often to ensure you're not removing too much metal from the tool.In conclusion, using marble or granite tile as a lapping plate can be a cost-effective and efficient way to keep your woodworking tools sharp and in good shape. It's an affordable alternative to expensive lapping plates and delivers the same results. With these simple steps, you can create a smooth and flat surface on your tools and produce excellent woodworking results. So, the next time you need to sharpen your tools, give this technique a try and experience the benefits.