Durable Machinery Components for Granite Processing

By:Admin

Granite Machinery Components, a leading manufacturer of high-quality machinery components, is proud to celebrate its 30th anniversary. Since its founding in 1991, the company has established itself as a trusted provider of precision-machined components for a wide range of industries, including automotive, aerospace, medical, and more.

Over the past three decades, Granite Machinery Components has built a strong reputation for its dedication to quality, innovation, and customer satisfaction. The company's state-of-the-art manufacturing facility is equipped with the latest technology and staffed by a team of highly skilled engineers and machinists, allowing them to produce components that meet the highest industry standards.

"We are thrilled to celebrate this significant milestone in our company's history," said the CEO of Granite Machinery Components. "Since our inception, we have been committed to delivering superior products and unmatched customer service, and it's a testament to our team's hard work and dedication that we have reached this 30-year mark."

Granite Machinery Components offers a wide range of manufacturing capabilities, including CNC milling, turning, grinding, and EDM machining. The company works closely with its customers to develop custom solutions that meet their specific needs, from small prototype runs to large-scale production.

In addition to its commitment to quality and precision, Granite Machinery Components places a strong emphasis on innovation and continuous improvement. The company invests in the latest manufacturing technology and regularly updates its processes to ensure that it remains at the forefront of the industry.

"Our dedication to innovation has been a key factor in our success over the past 30 years," said the CEO. "We continually invest in new technology and training for our team, allowing us to provide our customers with the most advanced and efficient machining solutions available."

As part of its anniversary celebration, Granite Machinery Components is looking forward to expanding its operations and reaching new milestones in the years to come. The company is planning to invest in additional manufacturing equipment and facilities to meet the growing demand for its products and services.

"We are excited about the future of the company and the opportunities that lie ahead," said the CEO. "Our team is committed to building on the success of the past 30 years and continuing to deliver the high-quality components and exceptional service that our customers have come to expect from us."

In addition to its dedication to excellence in manufacturing, Granite Machinery Components is also committed to giving back to the community. The company supports various charitable organizations and initiatives and is proud to play a role in making a positive impact on the world around them.

As Granite Machinery Components celebrates its 30th anniversary, the company looks back on its achievements with pride and looks forward to the next chapter in its journey. With a continued focus on quality, innovation, and customer satisfaction, the company is well positioned to remain a leader in the manufacturing industry for many years to come.

Company News & Blog

Top Suppliers of Inspection Tables Made of Granite for Efficient Cooking Function

When it comes to industrial workspaces like manufacturing and inspection facilities, having the right equipment and furniture is essential for ensuring optimal productivity, efficiency and accuracy. One of the most important pieces of equipment for inspection facilities is the Granite Inspection Table, which is used for precise measuring and inspection of small parts and components.Granite Inspection Tables are known for their high level of precision, accuracy, and durability, making them ideal for industrial applications. These tables are made with a granite surface plate, which is a flat and stable platform that is resistant to warping, scratching, and corrosion. The granite surface provides a stable reference point for taking precise measurements, and the tables are often used in conjunction with high-precision measuring tools like micrometers and dial indicators.When selecting a Granite Inspection Table, there are several factors to consider, including the size of the table, the weight capacity, and the type of work that will be performed on the table. Some tables may be designed for specific applications, such as measuring small parts or inspecting large machine components, while others are more general-purpose.Granite Inspection Tables can be found in a variety of sizes and configurations, including standalone tables, tables mounted on wheels or casters, and tables that are part of a larger inspection system. Some tables may also have built-in storage cabinets or drawers for storing measuring tools, gauges, and other accessories.In addition to their precision and accuracy, Granite Inspection Tables are also designed for ease of use and operator comfort. Many tables are designed with ergonomic features like anti-fatigue mats and adjustable height, which can help reduce strain and fatigue on the operator.Overall, Granite Inspection Tables are an essential piece of equipment for industrial inspection facilities, providing a stable and accurate platform for precise measurement and inspection. With their robust construction, precision accuracy, and ergonomic design, they are an excellent investment for any industrial workspace. So, if you are looking for a reliable and durable Granite Inspection Table, be sure to choose a quality supplier that specializes in these products.

High Chromium White Iron Castings for Wear Resistance on Inspection Surface Plates - Affordable Prices Available from Manufacturers in China

Cast Iron Surface Inspection Plate Factory: The Importance of Quality InspectionWhen it comes to manufacturing and testing equipment, quality and precision are of the utmost importance. In industries such as automotive, aerospace, and construction, precise measurements and accurate testing are essential. This is where cast iron surface inspection plates come into play.Cast iron surface inspection plates are designed to provide a flat, stable, and smooth surface for use in measuring equipment and machinery. They are used for a variety of purposes, such as testing the accuracy of machines, checking the flatness of surfaces, and measuring the thickness of objects.But not all cast iron surface inspection plates are created equal. The quality of these plates can vary depending on the manufacturer and the materials used. This is why it is important to choose a reputable Cast Iron Surface Inspection Plate Factory.At a reputable factory, the plates are manufactured with high-quality materials and undergo rigorous testing and inspections to ensure they meet the highest standards. Casting is done in state-of-the-art facilities, and the composition of the iron is carefully controlled to ensure consistent quality.One of the key factors that affect the quality of cast iron surface inspection plates is the composition of the iron. High chromium white iron is used for wear-resistant castings, while cement polished board carbon and silicon content is low. Carbon mainly exists in cementite form, and the fracture surface is carefully analyzed to identify the manufacturing process and any potential defects.Another important factor to consider is the finishing of the plates. The surface must be perfectly flat and free from any defects or irregularities. Advanced techniques such as lapping and measuring ensure that the plates meet exacting standards.In addition to providing high-quality cast iron surface inspection plates, reputable factories also offer customized solutions to meet the specific needs of customers. This includes plates of different thicknesses, sizes, and shapes, as well as special coatings and finishes.In conclusion, choosing a reputable Cast Iron Surface Inspection Plate Factory is crucial for ensuring the highest quality and precision in manufacturing and testing equipment. With the right materials and manufacturing processes, cast iron surface inspection plates can provide the reliable and accurate measurements that industries depend on.

High-Quality Granite Slabs for Your Kitchen Remodel in Maryland - Order Now!

Granite Slabs: A Timeless Addition to Your KitchenThe kitchen is the heart of every home. It’s where meals are cooked, families bond and memories are made. As the kitchen is such an important space, it’s essential to have it designed in a way that reflects your style and personality. One of the best ways to achieve this is by installing granite slabs.Granite is a type of natural stone that has been used for centuries. It’s a popular choice for kitchen countertops because it’s durable, heat-resistant and easy to maintain. But why stop at just countertops? Granite slabs can be used for a variety of purposes in your kitchen, from backsplashes to flooring.At KNC Granite, we offer the top-rated granite slabs in Maryland. Our slabs come in a variety of colors and patterns, allowing you to choose the perfect one for your kitchen. Here are some of the benefits of having granite slabs in your kitchen:DurabilityGranite is one of the most durable materials available for kitchen surfaces. It’s resistant to scratches, heat, and stains, making it perfect for busy kitchens. With proper care, your granite slabs can last for decades, making it a smart investment.Easy MaintenanceGranite is very easy to maintain. All you need to do is wipe it down with a damp cloth and mild soap to keep it looking new. Unlike other materials that require regular sealing and polishing, granite slabs require minimal upkeep.Timeless AppealGranite has been used in kitchens for centuries and it continues to be a popular choice today. Its timeless appeal means that it won’t go out of style anytime soon. Whether your kitchen is contemporary or traditional, granite slabs will complement any design.VersatilityGranite slabs can be used for a variety of purposes in your kitchen. They can be used as countertops, backsplashes, flooring, and even as decorative accents. With so many options to choose from, you can create a cohesive look throughout your kitchen.Small Granite Surface PlateIf you’re not ready to commit to a full kitchen renovation, a small granite surface plate is a great option. It can be used as a cutting board, cheese board, or even as a decorative piece on your kitchen island. A small granite surface plate is a budget-friendly way to add the beauty and durability of granite to your kitchen.In conclusion, granite slabs are a timeless addition to any kitchen. At KNC Granite, we offer the top-rated granite slabs in Maryland. With our variety of colors and patterns, you’re sure to find the perfect granite slab for your kitchen. Whether you’re looking to replace your countertops or add a small granite surface plate, we’ve got you covered. Contact us today to learn more about our granite slabs and to schedule a consultation.

High-Quality Cast Iron Bed Plates for Manufacturing Applications

The renowned cast iron bed plates manufacturer has been making headlines lately with its innovative products and cutting-edge technology. With a rich history of over [XX] years in the industry, the company has established itself as a leader in the manufacturing of high-quality cast iron bed plates for various industrial applications.The company's journey began in [year] when it was founded by a team of passionate engineers and entrepreneurs. Since then, it has grown exponentially and has continuously expanded its product line to cater to the diverse needs of its customers. The company takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and technology to ensure precision and quality in every product.One of the key strengths of the company lies in its dedicated team of professionals who bring a wealth of experience and expertise to the table. From product design and development to manufacturing and quality control, the company's team works tirelessly to deliver top-notch cast iron bed plates that meet the highest standards of quality and performance.In addition to its commitment to quality, the company also places a strong emphasis on innovation. It continuously invests in research and development to stay ahead of the curve and bring new and improved products to the market. The company's constant drive for innovation has led to the development of advanced materials and designs that offer unparalleled performance and durability.Moreover, the company prides itself on its ability to customize its products to meet the specific requirements of its clients. Whether it's a unique design, size, or material specification, the company has the capability to tailor its products to suit the individual needs of its customers. This flexibility and customer-centric approach have earned the company a loyal and satisfied customer base across the globe.The company's cast iron bed plates find applications in a wide range of industries, including automotive, aerospace, energy, and heavy machinery. These bed plates are known for their superior flatness, dimensional stability, and resistance to wear and tear, making them the top choice for demanding applications where precision and reliability are paramount.In addition to its focus on product excellence, the company is also dedicated to sustainability and environmental responsibility. It has implemented various initiatives to reduce its environmental footprint, including the use of eco-friendly materials and energy-efficient manufacturing processes. By prioritizing sustainability, the company not only benefits the environment but also contributes to the long-term success and reputation of its brand.Looking ahead, the company has ambitious plans for the future. It aims to further expand its global presence and reach new markets, while continuing to push the boundaries of innovation and technology in the manufacturing of cast iron bed plates. With a strong foundation built on quality, innovation, and customer satisfaction, the company is well-positioned to achieve its goals and maintain its leadership position in the industry.In conclusion, the renowned cast iron bed plates manufacturer has established itself as a powerhouse in the industry, with its steadfast commitment to quality, innovation, and customer satisfaction. With a rich history, a talented team, and a focus on sustainability, the company is well-equipped to thrive in an ever-evolving market. As it continues to push the boundaries of manufacturing excellence, the company is set to shape the future of the industry and set new benchmarks for quality and innovation.

Top Supplier of Granite Surface Plates for Industrial Use

[Title: Leading Granite Surface Plate Supplier Continues to Redefine Precision Measurement StandardsIntroduction:In today's fast-paced industrial landscape, precision and accuracy play crucial roles in manufacturing processes across various sectors. Offering the highest quality granite surface plates, one leading supplier, renowned for its commitment to excellence and innovation, has emerged as the go-to choice for businesses seeking unmatched precision in measurements. Through its dedication to research and development, this pioneering company has successfully redefined industry standards for precision measurement.Body:1. Legacy and Expertise:With a rich history spanning over several decades, this market-leading granite surface plate supplier has built a strong reputation based on its unwavering commitment to quality. Backed by extensive industry knowledge and experience, the company has become a household name synonymous with precision measurement tools. This trust stems from its consistent track record in delivering granite surface plates that conform to the highest industry standards.2. Cutting-edge Manufacturing Facilities:Utilizing state-of-the-art manufacturing facilities, the supplier ensures that each granite surface plate is crafted with impeccable precision and durability. The use of advanced machinery, combined with stringent quality control measures, guarantees that every product exceeds customer expectations. By investing in the latest manufacturing technologies, the supplier constantly strives to innovate and improve its product offerings to match evolving industry demands.3. Comprehensive Range of Granite Surface Plates:Recognizing the diverse needs of customers across industries, the supplier offers a comprehensive range of granite surface plates. From small-scale precision tools to large, heavy-duty plates, the company caters to the requirements of businesses of all sizes. Moreover, as a customer-centric organization, the supplier also provides customizable options, allowing clients to tailor the surface plates to their specific needs.4. Highest Quality Materials:At the heart of its manufacturing process, the supplier utilizes the finest quality granite obtained from trusted sources. This choice of material ensures the durability, stability, and longevity of its surface plates. Special care is taken during sourcing and processing to maintain the integrity and consistency of the granite, enabling the supplier to deliver products of unyielding quality.5. Industry Applications and Benefits:The precision offered by granite surface plates has made them indispensable tools across various industries. From automotive and aerospace to electronics and machining, these plates provide a stable and accurate surface for measurements and inspections. By investing in granite surface plates from this trustworthy supplier, businesses can reduce errors, optimize processes, and ensure the highest level of quality in their end products.6. Customer Satisfaction and Support:This prominent supplier places utmost importance on customer satisfaction and support. From initial inquiry to post-purchase assistance, the company's dedicated customer service team ensures a seamless experience for every client. By providing prompt responses, technical expertise, and reliable after-sales support, the supplier aims to forge long-term partnerships with its customers.7. Embracing Sustainability:In addition to its commitment to precision and customer satisfaction, the supplier recognizes its responsibility towards environmental sustainability. The company adheres to eco-friendly practices throughout its operations, ensuring minimal waste generation and maximum recycling efforts. By prioritizing sustainable manufacturing, the supplier strives to reduce its carbon footprint and contribute positively to the environment.Conclusion:Through its unwavering dedication to precision, innovation, and customer satisfaction, this renowned granite surface plate supplier continues to redefine the standards of precision measurement in the industry. With its cutting-edge manufacturing facilities, diverse product range, and commitment to sustainability, the supplier remains a trusted partner for businesses seeking exceptional accuracy in their measurement processes. As industries continue to evolve, this leading supplier's relentless pursuit of excellence ensures that it remains at the forefront of precision measurement solutions.]

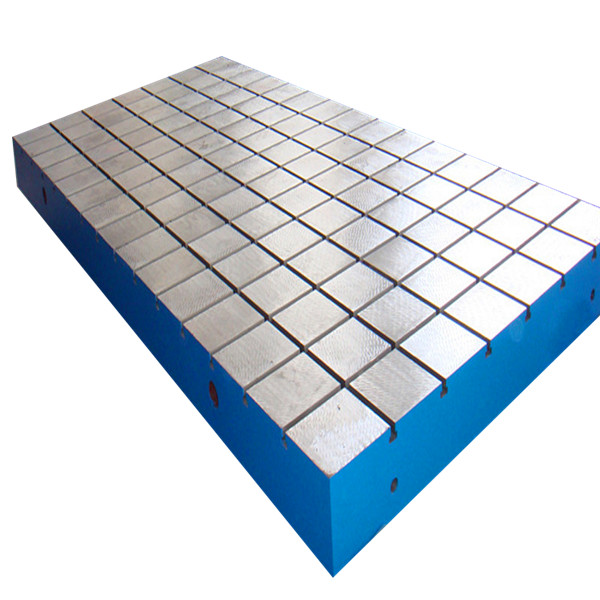

Premium Cast Iron T-Slotted Bottom Plates: A Reliable Supplier Emerges in the News

Title: Leading Supplier of Cast Iron T-Slotted Bottom Plates Sets the Benchmark in Precision EngineeringIntroduction:In the field of precision engineering, the selection of high-quality tools and equipment plays a crucial role in ensuring accurate results. Among the essential pieces of equipment for various industries, one particular component that stands out for its versatility and reliability is the cast iron T-slotted bottom plate. These heavy-duty plates serve as a foundation for a wide range of applications, including precision manufacturing, metrology, and laboratory testing.Company Introduction:{Company Name}, a prominent player in the precision engineering industry, has established itself as a leading supplier of cast iron T-slotted bottom plates. With an unwavering commitment to quality, innovation, and customer satisfaction, {Company Name} has become a trusted partner for businesses across various sectors.Renowned for their state-of-the-art manufacturing facilities and skilled workforce, {Company Name} provides customers with an unparalleled range of cast iron T-slotted bottom plates. Their products are meticulously crafted using the finest materials, ensuring durability and precision in every aspect.News Content:{Company Name}, a pioneer in the field, continues to set the benchmark for cast iron T-slotted bottom plates with their latest product release. Their commitment to staying at the forefront of technology and delivering excellence is evident in the innovative features incorporated into their new line of plates.One of the standout features of {Company Name}'s cast iron T-slotted bottom plates is their exceptional flatness tolerance. Through advanced manufacturing techniques and stringent quality control measures, these plates maintain an extraordinary level of flatness, ensuring optimal performance for precision applications. The superior flatness allows for accurate positioning and seamless integration with other equipment, resulting in enhanced productivity.Furthermore, {Company Name} recognizes the importance of adaptability and versatility in today's fast-paced industries. Their cast iron T-slotted bottom plates come with a variety of slot configurations, enabling customers to customize and reconfigure their setups to suit their specific needs. This versatility enhances operational efficiency and provides businesses with the flexibility required to adapt to evolving requirements.In addition to their unrivaled precision and versatility, {Company Name}'s cast iron T-slotted bottom plates also offer exceptional stability and rigidity. The robust construction of these plates ensures a solid foundation, minimizing vibrations and optimizing the performance of equipment mounted on their surfaces. This stability is crucial in precision machining operations where even the slightest deflection can result in substandard results.{Company Name} understands the significance of quality assurance, particularly in industries dependent on precision. To guarantee the highest standards, the company conducts rigorous testing on all its cast iron T-slotted bottom plates. Employing cutting-edge metrology equipment, each plate undergoes thorough inspections to ensure dimensional accuracy, flatness, and surface finish. This commitment to quality provides customers with the assurance that they are investing in a reliable and long-lasting product.Beyond manufacturing top-notch cast iron T-slotted bottom plates, {Company Name} also places great emphasis on customer satisfaction. Their knowledgeable and experienced team of experts is readily available to provide guidance and support, helping customers make informed decisions based on their unique requirements. Whether it's selecting the right plate configuration or providing technical assistance, {Company Name} prioritizes customer satisfaction from the initial consultation to the timely delivery of orders.In conclusion, {Company Name} has firmly positioned itself as a reliable and leading supplier of cast iron T-slotted bottom plates. Their commitment to quality, innovation, and customer satisfaction has set them apart in the precision engineering industry. By providing exceptional precision, adaptability, stability, and unparalleled customer service, {Company Name} continues to raise the bar in meeting the diverse needs of industries that rely on precision instruments and equipment.

Precision Surface Plate: The Complete Guide

[Company Introduction]The company is a leading manufacturer and supplier of high-quality industrial equipment and tools. With years of experience and a strong reputation in the industry, they have been dedicated to providing top-notch products to meet the needs of various manufacturing and engineering sectors. The company's commitment to precision, quality, and reliability has made them a trusted partner for countless businesses around the world.[News Content]The Cast Iron Precision Surface Plate is a game-changer for industries that require precision and accuracy in their manufacturing processes. This heavy-duty surface plate is designed to provide a stable and reliable platform for performing various machining and inspection tasks with the highest degree of accuracy.Manufactured using premium quality cast iron, this precision surface plate is meticulously hand-scraped to ensure a perfectly flat and smooth surface. The surface is then hand-finished to achieve the highest level of flatness and parallelism, making it an essential tool for ensuring the accuracy of machining operations and the quality of finished products.The precision surface plate is available in a wide range of sizes and configurations to meet the diverse needs of different industries. Whether it's used for inspecting the flatness of a workpiece, setting up machining operations, or as a reference surface for measuring tools, this versatile tool offers unparalleled precision and reliability.The company's dedication to quality and precision is evident in every aspect of the Cast Iron Precision Surface Plate. From the selection of the finest materials to the meticulous manufacturing and inspection processes, every step is taken to ensure that the end product meets the highest standards.The precision surface plate is not only a superior tool for achieving precision in manufacturing processes, but it also offers exceptional durability and longevity. Its robust construction and high-quality materials make it a reliable investment for any workshop or manufacturing facility.Furthermore, the company's renowned commitment to customer satisfaction is reflected in the exceptional service and support they provide. Customers can expect expert guidance in choosing the right precision surface plate for their specific needs, as well as ongoing technical support to ensure optimal performance and longevity.In addition to the Cast Iron Precision Surface Plate, the company offers a comprehensive range of high-quality industrial equipment and tools to meet the diverse needs of their customers. From cutting tools and machining accessories to measurement instruments and workholding solutions, they are a one-stop-shop for all industrial manufacturing needs.With a strong focus on innovation and continuous improvement, the company is constantly striving to bring new and improved products to market, ensuring that their customers have access to the latest advancements in industrial technology.In conclusion, the Cast Iron Precision Surface Plate offered by the company is a testament to their unwavering commitment to quality, precision, and customer satisfaction. With its exceptional flatness, durability, and versatility, this precision tool is a valuable asset for any manufacturing or engineering operation that demands the highest level of accuracy and reliability. When it comes to precision machining and inspection, the company's precision surface plate is the go-to choice for professionals who demand nothing but the best.

Discover the Benefits of Carbon Steel Wedges for Various Applications

Carbon Steel Wedges: Offering Strong and Effective Solutions for Industrial ApplicationsWedges are one of the most vital tools that industries use to hold objects in place, create tension, and provide a strong grip. They are an essential component of various industrial applications, including construction, automotive, and manufacturing. Carbon steel wedges are particularly popular due to their high strength and durability.({Company name removed}) is a leading manufacturer of carbon steel wedges for industrial applications. With over years of experience in the industry, the company has established itself as a trusted name for providing quality products to its clients.The company's carbon steel wedges are manufactured using premium quality materials to ensure they deliver excellent performance, durability, and strength. They are designed to provide a strong and effective grip to hold objects in place, even under heavy loads and high pressure.({Company name removed}) provides a wide range of carbon steel wedges, including tapered, square, and flat wedges, to cater to various industrial applications. The tapered wedge is the most commonly used type and can be used in a variety of applications, such as woodwork, automobile maintenance, and heavy machinery assembly.The square wedge is another popular type, and it's used to create tension and provide a strong grip for holding objects in place. They are typically used in construction work, particularly in foundations and retaining walls.Flat wedges are used to hold objects in place and prevent them from moving. They're also used as a tool for leveling surfaces such as bricks, stones, and tiles. They're typically used in construction and masonry work.({Company name removed})'s carbon steel wedges are made to withstand extreme temperatures and harsh environments. They're heat-treated to provide exceptional strength and durability, which makes them ideal for heavy-duty industrial applications.In addition to providing high-quality carbon steel wedges, ({Company name removed}) also offers customized solutions to meet specific customer requirements. The company works closely with its clients to understand their needs and provide tailor-made solutions that meet their unique requirements.({Company name removed}) understands the importance of delivering quality products and timely services to its customers. The company has a team of highly skilled professionals who are dedicated to providing top-notch products and services to its clients.With a reputation for delivering quality products and services, ({Company name removed}) has established itself as a trusted brand in the industrial sector. Its commitment to providing high-quality products and services has earned the company a loyal customer base.In conclusion, carbon steel wedges are an essential tool for many industrial applications, providing a strong and effective grip for holding objects in place. ({Company name removed})'s carbon steel wedges are renowned for their quality, strength, and durability and are a popular choice for many industries. With its commitment to customer satisfaction and providing customized solutions, ({Company name removed}) continues to be a leading name in the manufacturing of carbon steel wedges.

T-Slotted Floor Plates for Engineering Industry Applications

T-Slotted Floor Plates - An Essential Tool In The Engineering IndustryEngineering industries require durable and reliable equipment to facilitate efficient operations. The essential tools required include T-Slotted Floor Plates, which have a variety of uses within the industry. Some of the crucial benefits of using T-slotted floor plates are as follows:Rigid bases for layout marking and inspectionIn the engineering industry, accuracy is essential; thus, T-Slotted Floor Plates serve as a rigid base for layout, marking and inspection. The plates are made of cast iron, which provides the necessary strength and durability required for demanding applications. Additionally, the T-slots on the plates facilitate effortless anchoring of tools and inspection instruments, ensuring that they remain in the correct position. Ideal for assembly workT-slotted floor plates are also utilized in assembly work. They serve as an excellent base for large fixtures, special tooling, and production setups. The cast iron material can withstand heavy machinery and tools, making it suitable for precisions assembly work.Minimizes downtimeT-slotted floor plates provide a level surface, which minimizes the chances of machinery and component damages. In instances when machines and tools require maintenance or repair, the plates provide ample room for repairs without moving the machines. This minimizes downtime and increases productivity, which is crucial in the engineering industry.Customizable optionsT-slotted floor plates come in customizable sizes, including shape and design. The manufacturing industry provides clients with various options to meet their specific needs. A customized T-Slotted Floor Plate ensures specific components can be assembled at one time and boosts the accuracy of production set-ups.JASH Cast Iron T-Slotted Floor PlatesJASH Ltd is a leading manufacturer and supplier of cast iron T-slotted floor plates in India. JASH offers a wide range of floor plates, which is a preferred choice for various industries worldwide. The company ensures high quality in each product by using state-of-the-art technology in casting, machining, quality assurance, and customisation for its customers.JASH investment in modern technology enables them to manufacture and supply high-quality floor plates of various sizes, ranging from a width of 300mm to 6000mm and lengths of 1000mm up to a size of 12000mm. Each T-Slotted Floor Plate is subject to stringent testing to meet the high-quality requirements of the engineering and manufacturing industry. The quality-assurance process ensures that every plate meets the required specifications, providing clients with top-notch T-slotted floor plates.The cast iron material used by JASH ensures that the floor plates can withstand the heavy-duty requirements of the engineering and manufacturing industry. Additionally, customization ensures that clients' specific requirements are met, which improves overall productivity.In conclusion, JASH Ltd. offers a comprehensive range of products, including T-slotted floor plates, that can withstand all heavy-duty applications in the engineering industry. The customizable options provide clients with an array of choices, ensuring specific requirements are met. Clients can contact JASH for high-quality and durable T-slotted floor plates, which will improve the accuracy and productivity of their operations.

Advanced 3D Welding Tables for Modular Projects

Introducing a Revolutionary New Solution for Welding: 3D Modular Welding TablesWelding is a critical process in the manufacturing industry, and having the right equipment is essential for achieving high-quality results. That's why [Company Name] is proud to introduce a groundbreaking new solution for welding: 3D Modular Welding Tables. These innovative tables are set to revolutionize the way welding is done, offering unparalleled versatility, precision, and efficiency.[Company Name] has been a leader in providing cutting-edge solutions for the welding industry for over a decade. With a focus on innovation and quality, the company has continuously strived to develop products that meet the evolving needs of welders and fabricators. The introduction of 3D Modular Welding Tables is a testament to [Company Name]'s commitment to pushing the boundaries of what's possible in welding technology.The 3D Modular Welding Tables are designed to provide a comprehensive and flexible solution for a wide range of welding applications. Utilizing advanced 3D modeling and precision engineering, these tables offer unmatched accuracy and repeatability, ensuring that every weld is performed with the utmost precision. The modular design allows for easy customization, enabling welders to configure the tables to suit their specific needs and project requirements.One of the key features of the 3D Modular Welding Tables is their adaptability to various welding methods, including MIG, TIG, and Stick welding. This versatility makes these tables suitable for a diverse range of projects, from small-scale fabrication to large-scale industrial processes. Additionally, the tables are equipped with advanced clamping and fixturing systems, providing secure and stable support for workpieces of any size and shape.Moreover, the 3D Modular Welding Tables are constructed using high-quality materials that are built to withstand the rigors of the welding environment. The robust construction ensures durability and longevity, making these tables a wise investment for any welding operation. Furthermore, the tables are designed to be user-friendly, with intuitive controls and ergonomic features that make them easy to operate and maintain.In addition to their practical benefits, the 3D Modular Welding Tables also offer significant advantages in terms of efficiency and productivity. By streamlining the welding process and providing a stable and adaptable work surface, these tables can help welders complete their projects faster and with greater precision. This not only saves time and labor costs but also improves the overall quality of the finished welds.[Company Name] is committed to providing comprehensive support for its customers, and the introduction of the 3D Modular Welding Tables is no exception. In addition to offering high-quality products, the company also provides training and technical assistance to ensure that welders can make the most of their investment. This includes comprehensive instruction on using the tables effectively and efficiently, as well as ongoing support for any maintenance or troubleshooting needs.The introduction of 3D Modular Welding Tables represents a significant milestone for [Company Name] and the welding industry as a whole. With their unmatched precision, versatility, and efficiency, these tables are set to redefine the standards for welding equipment. Whether for small-scale fabrication or large-scale industrial projects, these tables offer a comprehensive solution that cater to the diverse needs of welders and fabricators.In conclusion, the introduction of 3D Modular Welding Tables marks a new era in welding technology, and [Company Name] is proud to be at the forefront of this exciting development. With their advanced features, user-friendly design, and comprehensive support, these tables are poised to become an indispensable tool for welders around the world. Whether for improving the quality of welds or streamlining the welding process, the 3D Modular Welding Tables are a game-changer that is sure to benefit the entire welding industry.