High-Quality Machine Components for Granite Materials

By:Admin

The new line of products from Granite Machine Components includes a wide range of machine components, including precision-ground granite surface plates, granite squares, granite parallels, and granite straight edges. These components are designed to provide accurate and reliable measurements for a variety of industrial applications, making them an essential tool for today's manufacturing industry. With their superior quality and durability, these components are built to withstand the rigorous demands of modern manufacturing environments.

Granite Machine Components has earned a strong reputation for delivering high-quality products that meet the industry's stringent standards. Their team of highly skilled engineers and technicians work tirelessly to ensure that each product meets the company's exacting standards for precision and performance. By leveraging advanced technology and innovative manufacturing processes, Granite Machine Components has continually raised the bar for excellence in the industry.

"We are thrilled to introduce our new line of products, which represent the latest advancements in machine component manufacturing," said the CEO of Granite Machine Components. "Our goal is to provide our customers with the most reliable and accurate components that will help them optimize their manufacturing processes and achieve greater efficiency. With our new line of products, we are confident that we can meet and exceed the needs of our customers, and we look forward to continuing to lead the industry in delivering top-quality machine components."

In addition to their commitment to producing high-quality products, Granite Machine Components also places a strong emphasis on customer satisfaction. The company prides itself on its responsive and knowledgeable customer service team, which is dedicated to providing support and assistance to customers throughout the entire purchasing process. Whether it's helping customers select the right components for their specific needs or providing technical support after purchase, Granite Machine Components is committed to ensuring that every customer is completely satisfied with their experience.

As a company with a strong focus on innovation and continuous improvement, Granite Machine Components is constantly exploring new ways to enhance their products and processes. Their research and development team is dedicated to staying at the forefront of advancements in the industry, enabling the company to anticipate and meet the evolving needs of their customers. With a strong emphasis on staying ahead of the curve, Granite Machine Components is well-positioned to continue leading the industry in providing state-of-the-art machine components.

With the launch of their new line of products, Granite Machine Components is poised to further solidify its position as a premier provider of machine components to the manufacturing industry. By delivering products that offer unmatched precision, durability, and reliability, the company is helping its customers achieve greater success in their respective industries. As they continue to push the boundaries of what is possible in machine component manufacturing, Granite Machine Components remains dedicated to providing the highest level of quality and service to its customers.

Company News & Blog

T-Slotted Plate: A Durable and Versatile Solution for Your Industrial Needs

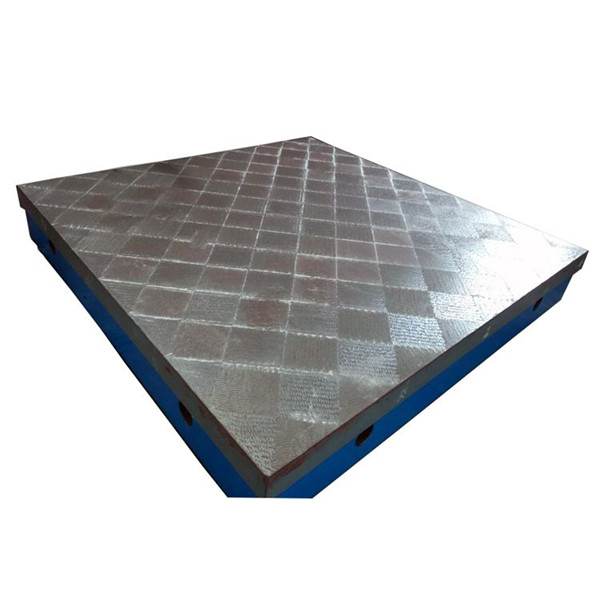

Cast Iron T-Slotted Plate Enhancing Industrial EfficiencyIn the realm of industrial manufacturing, companies are constantly striving to optimize their productivity and efficiency. One crucial element in achieving this goal is the utilization of high-quality equipment and machinery. Among these, the Cast Iron T-Slotted Plate has garnered a reputation for its outstanding performance and capability to streamline various industrial processes.The Cast Iron T-Slotted Plate is a versatile and robust plate made from high-quality cast iron. It features T-slots, which are grooves strategically positioned on the plate's surface. These slots allow for the easy and efficient attachment of fixtures, tooling, and workpieces, thus facilitating enhanced versatility, stability, and productivity during industrial operations.The cast iron construction of the plate ensures outstanding durability and reliability, making it suitable for heavy-duty applications in industries such as aerospace, automotive, machinery, and construction. Its superior structural integrity allows it to withstand high loads, vibrations, and thermal variations, ensuring consistent performance even in challenging environments.One of the key advantages of the Cast Iron T-Slotted Plate lies in its modularity. The T-slots provide a standardized mounting system, enabling easy and precise customization. This allows industrial operators to tailor the plate's configuration to meet the specific requirements of their applications. The modular nature of the T-slotted plate facilitates rapid and efficient reconfiguration, significantly reducing downtime during production line changes.The Cast Iron T-Slotted Plate is also renowned for its exceptional precision. The T-slots exhibit strict dimensional tolerances, ensuring that fixtures and tooling are securely positioned and aligned. This precision minimizes errors, increases repeatability, and enhances the overall accuracy of industrial operations. As a result, manufacturers can achieve improved quality control, higher machining tolerances, and reduced scrap rates.Furthermore, the Cast Iron T-Slotted Plate offers excellent versatility. Its modular design allows for the attachment of a wide range of accessories and components, such as clamps, supports, and sensors. This flexibility enables manufacturers to adapt to evolving production needs, experiment with new setups, and implement innovative techniques. Consequently, industrial processes become more adaptable, efficient, and cost-effective.The adoption of the Cast Iron T-Slotted Plate promotes a safer work environment. By securely fastening fixtures and tooling, the plate minimizes the risk of accidents caused by loose or shifting components. Its robust construction and resistance to vibrations further contribute to operator safety and reduced machinery wear, leading to reduced maintenance costs and improved worker well-being.Recognizing the significance of this game-changing industrial equipment, numerous companies have incorporated the Cast Iron T-Slotted Plate into their manufacturing processes. One such company is {}, a leading provider of advanced tooling solutions. Their expertise lies in delivering innovative products that enhance efficiency, productivity, and operator safety.With their extensive experience, {} comprehends the requirements of modern industrial operations. The incorporation of the Cast Iron T-Slotted Plate into their portfolio reflects their commitment to delivering reliable, high-performance solutions to their clients. By offering this cutting-edge equipment, they empower manufacturers to optimize their operations, enhance product quality, and maximize profitability.In summary, the Cast Iron T-Slotted Plate represents a significant advancement in industrial manufacturing equipment. Its durability, modularity, precision, versatility, and safety features make it an indispensable tool for various industries. As companies strive to enhance their efficiency and productivity, the adoption of the Cast Iron T-Slotted Plate has become a top priority. With its proven track record and endorsement by leading companies, this equipment continues to revolutionize industrial processes worldwide.

Large cast iron T-slotted angle plates for machinery and tooling accessories

Yoder Machinery Sales Offers High-Quality Angle Plates for Improved Precision and AccuracyYoder Machinery Sales, a leading provider of high-quality machinery and tools, is proud to offer a range of angle plates that are designed to improve precision and accuracy in machining operations. With over 70 years of experience in the industry, Yoder Machinery Sales has become a trusted name in providing top-quality machinery and accessories that meet the needs of various industries, including aerospace, automotive, and medical.As part of its commitment to delivering high-quality products, Yoder Machinery Sales offers two Giddings & Lewis T-slotted angle plates with the dimensions 31-1/2 W x 39-3/8 H x 24 D and cast iron construction. These angle plates, with the product number #70512, are designed to provide the necessary support and stability for machining operations, ensuring that precise and accurate cuts can be made. With two units available, clients have the flexibility to choose the number of angle plates that meet their needs.The angle plates available from Yoder Machinery Sales are beneficial for several reasons. Firstly, their cast iron construction makes them sturdy and durable, which means they can withstand the rigors of machining operations. Secondly, they are designed with T-slots to provide several options for workholding, providing the necessary flexibility in connecting various accessories and machines. Lastly, they come with a pre-machined surface that can be used as a reference surface, providing a solid foundation for machining operations.In addition to providing high-quality angle plates, Yoder Machinery Sales also offers a range of tooling and machinery accessories that are essential for machining operations. These accessories include collets, chucks, vises, rotary tables, cutting tools, and more. All products are sourced from reputable manufacturers, ensuring that clients receive top-quality products that meet their needs.One of the reasons why Yoder Machinery Sales is a trusted name in the industry is its commitment to providing excellent customer service. The company has a team of experienced professionals who are knowledgeable about the products and services offered. They work closely with clients to understand their needs, provide expert advice, and help them make informed decisions.Clients who work with Yoder Machinery Sales benefit from fast and reliable delivery, competitive pricing, and a range of payment options. The company accepts various payment methods, including credit cards, wire transfers, and financing. Additionally, for clients looking to sell their machinery or equipment, Yoder Machinery Sales offers consignment and auction services, ensuring that clients get the best value for their equipment.In conclusion, Yoder Machinery Sales is a trusted name in the industry, providing high-quality machinery and accessories that meet the needs of various industries. The Giddings & Lewis T-slotted angle plates with product number #70512 are an excellent addition to any machining operation, providing stability, support, and precision. With a range of tooling and machinery accessories available, clients can count on Yoder Machinery Sales to deliver top-quality products at competitive prices. For more information about Yoder Machinery Sales and the products and services offered, please visit their website or contact their sales team.

Easily Restore Your Blades with a High-precision Flat Surface Plate

, Cool Tools, Super Flat, Stone, Sharpening, Edge RestorationAre you tired of uneven, dull edges on your knives and other cutting tools? Look no further than the Granite Surface Plate from Cool Tools for super flat, precise edge restoration.Made from high-quality granite, this surface plate is incredibly durable and resistant to wear and tear. It's also easy to clean and maintain, with a non-porous surface that won't absorb any liquids or debris.But what really sets the Granite Surface Plate apart is its super flat surface. This makes it perfect for use in sharpening and restoring the edges of your tools, as any imperfections or unevenness in the surface can negatively affect the results.Using the Granite Surface Plate is simple. Just lay your tool on the surface, and use a sharpening stone or other edge restoration tool to work on the blade. The super flat surface ensures that you're working on a precise edge, and the hardness of the granite means that the plate won't wear down over time.Of course, the Granite Surface Plate isn't just great for sharpening. It can also be used for a variety of other tasks, such as measuring and inspecting. And because it's so versatile, it's a must-have for any serious DIYer or craftsman.So if you're tired of frustratingly uneven edges on your tools, check out the Granite Surface Plate from Cool Tools. With its super flat surface and unmatched durability, it's the perfect tool for any job that requires precision and accuracy.

How to Set Up Golf Wedges for Better Performance

Title: Innovative Wedge Set Up Revolutionizes Home Improvement ProjectsIntroduction:In the ever-evolving world of home improvement, a groundbreaking new product is poised to revolutionize how we approach small construction and remodeling projects. Set Up Wedges, a cutting-edge tool developed by an innovative company, offers homeowners, contractors, and DIY enthusiasts a reliable and efficient solution to simplify various tasks. Set Up Wedges have quickly gained popularity among professionals and hobbyists alike, thanks to their superior design and versatile applications.Company Introduction:{} is a prominent player in the home improvement industry. Known for their commitment to innovation and customer satisfaction, {} has consistently delivered high-quality products designed to make everyday tasks easier. With years of experience and a team of skilled engineers, they have successfully developed and launched Set Up Wedges, a game-changing tool that overcomes many of the traditional challenges faced during construction and remodeling projects.Paragraph 1:Set Up Wedges were created with the aim of streamlining and enhancing the efficiency of various home improvement tasks. From leveling countertops and cabinets to aligning doors and windows, these wedges provide a reliable solution for those demanding precision and accuracy. The clever design allows for straightforward installation, making it ideal for professionals and homeowners alike.Paragraph 2:One of the key features of the Set Up Wedges is their innovative reversible design, which offers dual functionality. Engineered with one flat and one angled side, these wedges can be used to level or elevate objects as needed, adapting to different project requirements with ease. This versatility significantly reduces the need for multiple tools and simplifies the workflow, resulting in time savings and increased productivity for users.Paragraph 3:The Set Up Wedges are made with durable and impact-resistant materials, ensuring their longevity even in highly demanding construction environments. Their compact size makes them portable and convenient, allowing contractors to carry them in their tool belts or homeowners to store them in their toolkit for immediate access. With their ergonomic shape and textured surface, these wedges provide a comfortable grip, ensuring stability during use.Paragraph 4:Unlike conventional leveling tools, Set Up Wedges are stackable, adding an additional layer of convenience. Each wedge interlocks securely with the next, forming a stable column that can be easily adjusted to reach the desired height. This unique stacking feature not only saves storage space but also enables users to customize height levels precisely, making the wedges exceptionally versatile.Paragraph 5:With increasing demand for eco-friendly solutions, Set Up Wedges stands out by being 100% recyclable. Designed with the environment in mind, {} has made a conscious effort to reduce waste and minimize the carbon footprint associated with their product. This commitment exemplifies the company's dedication to sustainable manufacturing practices, ensuring a greener future for users and the planet.Conclusion:Set Up Wedges have revolutionized the world of home improvement by providing an innovative solution to simplify various tasks. The tool's durable design, stackable feature, and reversible functionality make it a must-have for both professionals and DIY enthusiasts. With {}'s attention to detail, customer satisfaction, and commitment to sustainability, Set Up Wedges have quickly become a popular choice for those seeking an efficient and reliable tool for their construction and remodeling needs.

High Chromium White Iron Wear-Resistant Castings: A Guide to Precision Cast Iron T-Slot Surface Plate Manufacturers and Suppliers

Title: Unveiling the True Value of High Chromium White Iron Wear-Resistant Castings: A Comprehensive Guide to Cast-Iron Surface PlatesIntroductionIn the shifting landscape of manufacturing and industrial applications, precision, accuracy, and durability are crucial factors for success. When it comes to supporting heavy machinery or ensuring precise measurements, the choice of surface plates becomes paramount. One material that has gained significant attention in the industry is high chromium white iron wear-resistant castings. In this blog, we will delve into the world of cast-iron surface plates, discussing their introduction, advantages, and the essential considerations that contribute to their pricing.Chapter 1: Casting a Glance at Cast-Iron Surface Plates1.1 Understanding the Role: Introduction to Cast-Iron Surface Plates1.2 High Chromium White Iron Wear-Resistant Castings: A Game-Changing Material1.3 The Functionality of Cement Polished Boards in Cast-Iron Surface Plates1.4 Analyzing the Carbon and Silicon Content: Crucial Factors in Cast-Iron CompositionChapter 2: Exploring the Advantages of High Chromium White Iron Surface Plates2.1 Unparalleled Wear Resistance: The Cornerstone Attribute2.2 Cementite Formation: The Key to a Low Carbon Content2.3 Fracture Surface Analysis: An Insight into Cast-Iron Surface Plate Durability2.4 The Performance Benchmark: Examining the Carbon-Silicon RatiosChapter 3: The Price Complexity of High Chromium White Iron Surface Plates3.1 Factors Affecting the Pricing of Cast-Iron Surface Plates3.2 Material Sourcing and Production Costs3.3 Research and Development Investments: Advancements in Surface Plate Technology3.4 The Influence of Market Competition on Cast-Iron Surface Plate PricesChapter 4: Presenting the Cast-Iron Surface Plate Pricelist4.1 Analyzing the Different Pricing Tiers of Cast-Iron Surface Plates4.2 Factors Determining the Price Variability Among Manufacturers and Suppliers4.3 Exploring the Trade-Offs between Quality and Affordability in Surface Plate Selection4.4 Expert Opinions: The Value-for-Money Perspective in Cast-Iron Surface Plate InvestmentsConclusionCast-iron surface plates manufactured using high chromium white iron wear-resistant castings represent a significant advancement in the industry. With their unbeatable wear resistance, low carbon content, and remarkable durability, these surface plates have become a trusted choice for precision engineering and measurement applications. While pricing can be an essential consideration, it is crucial to evaluate the entire value proposition and invest wisely in high-quality cast-iron surface plates that align with specific business needs.In this blog, we have extensively discussed the introduction, advantages, and considerations related to cast-iron surface plates, shedding light on the complex factors that influence their pricing. By arming oneself with this knowledge, businesses can make informed decisions when selecting the ideal cast-iron surface plates that offer exceptional performance, longevity, and value for money.Keywords: Cast-Iron Surface Plate, High Chromium White Iron Wear-Resistant Castings, Cement Polished Boards, Carbon and Silicon Content, Cast-Iron Surface Plate Pricelist.

Stylish Metallic Wedges for Spring Celebrations!

: The Perfect Choice for SpringSpring is the season of blossoming flowers, warmer temperatures, and most importantly, pre-wedding parties. As the wedding season kicks off, it's time to dust off those stylish wedges that have been hiding in the back of your closet. Wedges are perfect for spring as they are comfortable and provide the necessary support to strut with confidence.This year, there's a twist to the usual wedge style – metallic accents. Wedges with metal embellishments like studs, buckles, or straps add an edgy touch to the traditional design, making them perfect for any casual or formal occasion.Not sure where to start your search for the perfect metallic accent wedges? Fret not, for we have listed our five favorite metal-accented wedges that are sure to elevate your outfit and have you walking in style.1. Metallic Flatform Wedges: These wedges add an extra lift to your height without compromising on comfort. The metallic buckle and strap detailing add a subtle glam to your outfit.2. Embossed Metallic Wedges: If you're looking for something unique and eye-catching, these embossed metallic wedges are just what you need. The intricate detailing on the wedge heel and metallic straps make them a perfect choice for any evening event.3. Peep-Toe Metallic Wedges: A pair of peep-toe metallic wedges are perfect for a daytime event. The open-toe design and metallic detailing on the wedge add sophistication to any outfit.4. Metallic Studded Wedges: If you're looking for an edgier look, these studded wedges are perfect. The metallic studs on the wedge add a rocker-chick vibe to the traditional wedge design, making them perfect for a night out with friends.5. Strappy Metallic Wedges: Delicate and feminine, these strappy metallic wedges are perfect for a beach wedding or daytime event. The metallic straps add a pop of shine to the natural surroundings, making them a stylish choice for any outdoor event.In conclusion, metallic-accented wedges are a must-have for any fashion-forward individual looking to add a stylish twist to their spring/summer wardrobe. Whether you're attending a wedding or just heading out for the day, these wedges are sure to elevate your outfit and have heads turning. So, kick up your heels and strut your stuff with confidence in these stylish metallic-accented wedges.

Ultimate Guide to Finding the Best Quality Spare Parts for Granite Machines

Granite Machine Spare Parts: A Leading Company in the Manufacturing IndustryGranite Machine Spare Parts is a leading manufacturer of high-quality granite machine spare parts. Established in 1994, the company has been providing its products to a wide range of customers around the world. With over two decades of experience, the company has developed a reputation for delivering top-quality products that meet the highest industry standards.The company is headquartered in a state-of-the-art facility located in China. This modern facility is equipped with the latest technology to ensure that all production processes are efficient and effective. The company also has a team of highly skilled professionals who work tirelessly to ensure that all products are of the highest quality.At Granite Machine Spare Parts, customers come first. The company is committed to providing exceptional customer service and making sure that customers are completely satisfied with their products. The company's team of sales representatives are highly knowledgeable about the products and can provide expert advice and guidance to customers.The company's product range is vast and includes a variety of machine spare parts, including spindles, bearings, belts, pulleys, and much more. The company's products are designed to meet the specific needs of different customers and are available in various sizes and specifications. The company uses only the highest quality raw materials to ensure that all products meet the highest industry standards.Granite Machine Spare Parts has been at the forefront of innovation in the manufacturing industry. The company invests heavily in research and development to ensure that its products are always cutting-edge and meet the changing needs of its customers. The company's team of engineers is constantly looking for new ways to improve products and manufacturing processes to make them more efficient and cost-effective.The company's commitment to quality is demonstrated by its adherence to strict quality control measures. All products undergo rigorous testing to ensure that they are of the highest quality before being shipped to customers. The company is also ISO 9001 certified, which is a testament to its commitment to quality.Granite Machine Spare Parts also places great emphasis on environmental sustainability. The company employs environmentally friendly manufacturing processes and uses materials that are safe for the environment. The company's commitment to sustainability is one of the many reasons why it has become a leading player in the manufacturing industry.In conclusion, Granite Machine Spare Parts is a leading manufacturer of high-quality granite machine spare parts. With over two decades of experience, the company has developed a reputation for delivering top-quality products that meet the highest industry standards. The company's commitment to quality, innovation, customer service, and sustainability has made it a trusted partner to a wide range of customers around the world. The company's focus on excellence and continuous improvement is sure to keep it at the forefront of the manufacturing industry for many years to come.

Shop Online Today for Affordable and High-Quality Measuring Tools with Next Day Delivery Available in the UK.

Granite Tools for Measuring: The Perfect Partner for Accurate EngineeringMeasuring tools are an essential element in the world of engineering. Without them, it would be impossible to accurately assess the dimensions, angles, and other aspects that are fundamental to the creation of precise and reliable products. Among the various options available in the market, Granite tools for measuring stand out as a great alternative due to their outstanding properties and benefits.Granite measuring tools are made of natural granite material, which is renowned for its exceptional stability, flatness, and consistent density. Granite is a hard stone that does not warp, rust, or wear easily, making it an ideal option for manufacturing measuring tools that require precise and consistent measurements. Moreover, granite tools offer excellent vibration-dampening capabilities, reducing the impact of external factors that could interfere with the accuracy of measurements.Granite measuring tools come in different shapes and sizes, depending on the specific application. There are granite squares, straight-edges, surface plates, and angles, among others. Each tool has its own unique features that make it suitable for measuring specific aspects of a component or machine. For instance, a granite surface plate is ideal for measuring flatness, parallelism, and straightness, while a granite angle plate is suitable for checking the squareness of a workpiece or machine parts.Granite measuring tools are widely used in various industries, including aerospace, automotive, machining, and metrology, among others. These tools are ideal for precision engineering and are commonly used for the calibration and inspection of other measuring instruments. Granite measuring tools are also used in research laboratories, where the accuracy and reliability of the data collected are critical.One of the most significant advantages of granite measuring tools is their long lifespan. Unlike other measuring tools made of aluminum or steel, granite tools can last for decades without losing their accuracy. With proper care and maintenance, these instruments can serve as a reliable partner for engineers and technicians for years to come, providing consistent and dependable measurements.In conclusion, Granite tools for measuring are a great investment for any engineering company or laboratory that aims to achieve precision and accuracy in their work. With their exceptional stability, flatness, and durability, these tools are ideal for measuring critical components and machines. Furthermore, granite measuring tools offer excellent value for money, as they can last for decades without losing their accuracy. So, if you want to ensure that your products meet the highest standards of quality, consider investing in granite measuring tools today.

DIY Granite Surface Plate: How to Make One with 3 Plates

When it comes to precision machining and measurement, having a reliable surface plate is crucial. While there are various types of surface plates available in the market, granite surface plates are one of the most widely used. However, buying such a plate can be expensive. Hence, some people opt to make their own using the 3 plates method. In this blog, we will discuss what materials are required to make a granite surface plate and the process involved.Materials RequiredBefore we delve into the process, it's essential to have all the necessary materials in place. Here's a list of things you'll need:- 3 surface plates- Epoxy- Two-part epoxy hardener- Sandpaper- LevelThe first step is to purchase three granite surface plates. It's vital that you buy high-quality plates that are flat and have a smooth surface. You don't need brand names when buying these plates; you can get generic ones at a lower price.ProcessOnce you have all the required materials, you can start the process of making your surface plate. Here are the steps involved:1. Clean the surface platesBefore bonding the plates together, ensure that they are clean. You can use a damp cloth to wipe away any dirt and dust particles.2. Level the surface platesUse a level to ensure that all the surface plates are horizontal. If one or two of the plates are not level, it will affect the overall accuracy of the surface plate.3. Prepare the epoxyFollow the instructions on the epoxy packaging and mix the two-part epoxy hardener thoroughly.4. Apply the epoxyApply a 1/8 inch of epoxy evenly on each surface. Be sure to apply it in a thin layer and avoid any air bubbles.5. Put the plates togetherCarefully place the three surface plates on top of each other. Ensure that the plates align correctly.6. Leave it to cureLet the epoxy cure according to the manufacturer's instructions. It usually takes about 24 to 48 hours to cure fully.7. Finish the surface plateOnce the epoxy has cured, use sandpaper to smoothen any rough spots or bumps on the surface. Be gentle when using the sandpaper, so you do not risk damaging the surface plate.8. Test the surface plateBefore using your newly made surface plate, verify its accuracy using a dial indicator. If it's not accurate, you may need to repeat the process.Advantages of Making Your Surface PlateMaking your surface plate is a cost-effective alternative to buying one. It's ideal for individuals who require a surface plate for occasional use but can't afford to invest in an expensive one. Making your surface plate also gives you the flexibility to customize it according to your needs.ConclusionIn conclusion, making a granite surface plate using the 3 plates method is achievable. With the right materials and patience, you can create a flat, accurate, and reliable surface plate. As a bonus, you get the satisfaction of knowing that you made something useful with your own hands.

Benefits of Using T-Slotted Cast Iron Floor Plates for Industrial Applications

article:Cast Iron T Slotted Floor Plate: The Ultimate Solution for Industrial WorkshopsIndustrial workshops require specialized equipment to improve workflow and efficiency. A crucial part of the equipment includes workstations with high-performing floors to effectively carry out tasks and ensure workers' safety. This is where Cast Iron T Slotted Floor Plate comes in.The Cast Iron T Slotted Floor Plate is an essential equipment in industrial workshops and foundries. It is a flat, sturdy metal plate that rests on the workshop floor to provide a level, stable, and reliable base for heavy-duty machinery and equipment. The Cast Iron T Slotted Floor Plate is usually made from high-grade cast iron with T-slots milled into the plate to allow for secure and flexible clamping of tools, instruments, and machinery.These T-slots placed at regular intervals on the Cast Iron T Slotted Floor Plate make it an ideal solution for many workshop applications. The slots can be used to bolt tools to the floor, thus increasing the wrokstation's accuracy, efficiency and stability as compared to other methods.Each Cast Iron T Slotted Floor Plate is created with T-slots that are designed to ANSI and DIN standards, ensuring compatibility with most standard socket-head bolts. Also, the manufacturing process incorporates high-precision milling that guarantees a tight fit, thus eliminating movement or vibration in the work stations and ensuring safe working conditions.Industrial workshops often require materials that are resistant to environmental factors such as wear and tear, heavy loads, and extreme temperature changes. The Cast Iron T Slotted Floor Plate is able to withstand extreme temperatures change, making it perfect to withstand wear and tear over time. The Cast Iron T Slotted Floor Plate can also be machined to fit specific needs, reducing workshop downtime and enhancing work speed.Although Cast Iron T Slotted Floor Plates are useful for a wide range of applications, they are primarily used in CNC machines, welding tables, assembly lines, and mill processing. They are also suitable for heavy-duty induction hardening applications and are ideal for applications requiring substantial weight-bearing capacity.At their core, Cast Iron T Slotted Floor Plates are a measure of industrial workstations' efficiency and safety. They provide a stable platform for workers to carry out their tasks, secure clamping of tools, and reliable industrial equipment. Cast Iron T Slotted Floor Plates have become staples in industrial workplaces due to their versatility, durability, and precision.A well-manufactured Cast Iron T Slotted Floor Plate supports heavy machinery and equipment, eliminates harmful vibrations, and ensures the safety of all who use and service the machinery and equipment.Getting the best Cast Iron T Slotted Floor Plate requires experience and expertise. With diverse manufacturers across the world, such as the US-based Flint Machine Tools, selecting the right manufacturer is the first step in acquiring these cast iron plates.Flint Machine Tools has been reliably producing high-quality Cast Iron T Slotted Floor Plates that meet statutory guidelines since 2001. The company has a high-quality testing standard that ensures its Cast Iron T Slotted Floor Plates are of unparalleled quality. Their milling process of Cast Iron T Slotted Floor Plate offers perfect flatness, and their T-slots are effectively milled to the ANSI and DIN standards.To promote safety and precision in the workshop, Flint Machine Tools' Cast Iron T Slotted Floor Plate features countersunk holes to hide bolts' heads, ensuring a flush fit. Additionally, they are milled with accurately positioned T-slots, which offer flexibility in clamp positioning.In conclusion, Cast Iron T Slotted Floor Plate is an essential part of industrial workshops and foundries. With the versatility, resilience, and precision provided, the Cast Iron T Slotted Floor Plate is an important investment for workshop owners looking to enhance their work stations. As a trusted manufacturer of these essential plates, Flint Machine Tools has been a reliable supplier for over twenty years. Choosing their Cast Iron T Slotted Floor Plates will give workshop owners peace of mind as they work in a safe, stable, and efficient environment.