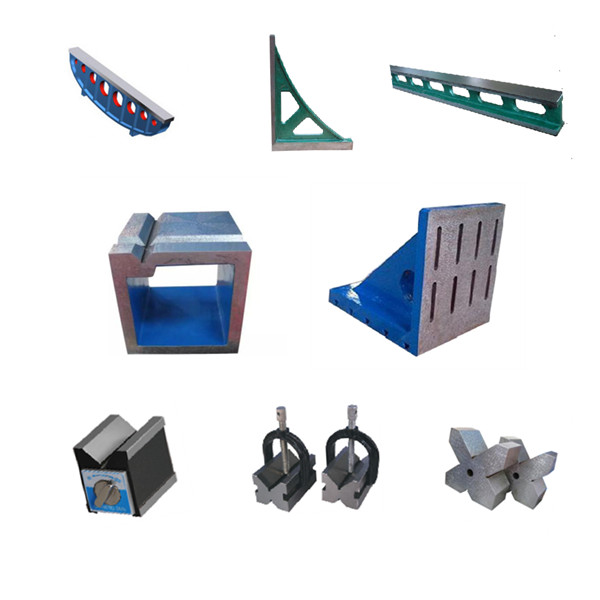

Quality Tools for Accurate Measurement in Granite Industry

By:Admin

Today, we will take a closer look at the company {} and their contribution to the world of measuring tools. {Company} is a leading manufacturer of Granite Tools For Measuring, known for their high-quality products and innovative designs. With a focus on precision and reliability, {Company} has earned a reputation for excellence in the industry.

One of the key features of Granite Tools For Measuring from {Company} is their advanced technology. These tools are equipped with cutting-edge measuring systems that allow for incredibly accurate and consistent results. This technology has revolutionized the way granite is measured and cut, making it easier than ever for professionals to achieve the perfect fit and finish.

In addition to their advanced technology, {Company}'s Granite Tools For Measuring are also built to last. Made from high-quality materials such as stainless steel and aluminum, these tools are designed to withstand the rigors of the job site. This durability ensures that professionals can rely on their Granite Tools For Measuring for years to come, making them a sound investment for any business.

Furthermore, {Company} offers a wide range of Granite Tools For Measuring to meet the diverse needs of their customers. From simple handheld measuring devices to advanced laser-guided systems, {Company} has a solution for every project. This versatility has made {Company} a trusted name in the industry, with professionals around the world turning to their products for their measuring needs.

In addition to their innovative products, {Company} also provides exceptional customer service. Their team of experts is always on hand to provide support and guidance to professionals using their Granite Tools For Measuring. Whether it's technical assistance or product recommendations, {Company} is committed to helping their customers succeed.

Looking ahead, {Company} is dedicated to continuous improvement and innovation. They are constantly researching and developing new technologies to further enhance their Granite Tools For Measuring. By staying at the forefront of the industry, {Company} is ensuring that their products will continue to meet the evolving needs of professionals in the construction and architecture fields.

In conclusion, Granite Tools For Measuring from {Company} are a testament to the company's commitment to quality and innovation. With their advanced technology, durability, and versatility, these tools have become an essential part of the industry. Professionals can rely on {Company} for precision and reliability, knowing that their Granite Tools For Measuring will help them achieve outstanding results. With a dedication to customer service and a focus on continuous improvement, {Company} is a leader in the world of measuring tools, and their impact on the industry is sure to endure for years to come.

Company News & Blog

Innovative 3D Welding Tables for Modular Fabrication

3D Modular Welding Tables Revolutionize Manufacturing IndustryWelding is an essential process in the manufacturing industry, and finding the right tools to enhance productivity and efficiency is crucial. This is where 3D Modular Welding Tables come in, offering a groundbreaking solution that is set to revolutionize the way welding is done in the industry.3D Modular Welding Tables, manufactured by [], are innovative fixtures that provide a versatile and efficient platform for welding various components. These tables are designed to be modular, allowing for easy customization and reconfiguration to accommodate different welding projects. The unique design of the tables incorporates a grid pattern with regularly spaced holes, providing a secure and flexible clamping system for workpieces.The key feature of 3D Modular Welding Tables is their adaptability. The modular nature of these tables allows users to create a customized work surface by combining different table modules, ensuring that they meet the specific requirements of each welding project. This flexibility not only streamlines the welding process but also eliminates the need for multiple specialized fixtures, ultimately saving time and cost.Furthermore, the precision and accuracy of 3D Modular Welding Tables contribute to the overall quality of welded products. The grid pattern of holes on the table surface allows for precise positioning of workpieces, ensuring that they are securely held in place during the welding process. This level of stability and control results in superior welding accuracy, ultimately leading to higher quality welded components.Another notable advantage of 3D Modular Welding Tables is their ability to streamline workflow and improve productivity. The versatility of these tables allows for quick and easy reconfiguration, minimizing downtime between welding projects. Additionally, the secure clamping system ensures that workpieces are held firmly in place, reducing the risk of rework and rejections due to welding inaccuracies.In addition to their practical benefits, 3D Modular Welding Tables are also designed with user convenience in mind. The ergonomic design of the tables provides a comfortable and efficient working environment for welders, ultimately contributing to improved work quality and reduced fatigue during extended welding tasks.Furthermore, the durability and longevity of 3D Modular Welding Tables make them a cost-effective investment for manufacturing companies. Made from high-quality materials, these tables are built to withstand the rigors of industrial welding environments, ensuring reliable performance and longevity.Manufacturing companies that have integrated 3D Modular Welding Tables into their operations have reported significant improvements in their welding processes. The versatility and adaptability of these tables have allowed them to take on a wider range of welding projects, ultimately expanding their capabilities and increasing their competitiveness in the industry.Overall, 3D Modular Welding Tables have emerged as a game-changer in the manufacturing industry, offering a versatile, efficient, and cost-effective solution for welding processes. The innovative design, precision, and adaptability of these tables have set a new standard for welding fixtures, ultimately paving the way for enhanced productivity and superior quality in the manufacturing sector.With their proven track record of improving welding processes and delivering exceptional results, 3D Modular Welding Tables are poised to become an indispensable tool for manufacturing companies looking to optimize their welding operations. As the manufacturing industry continues to evolve, these tables are set to play a crucial role in driving efficiency, productivity, and quality in the welding process.

Georgia museum showcases conflicting sides of Soviet leader Joseph Stalin

Joseph Stalin: A Tale of Two Personalities at a Georgia MuseumJoseph Stalin is a historical figure shrouded in controversy. He is often remembered as a ruthless Soviet dictator who ruled with an iron fist, spreading fear and terror throughout the Soviet Union. However, a museum in the Georgian village of Gori, Stalin's birthplace, is shedding light on the softer, sentimental side of the Soviet ruler that many have never seen before.The Joseph Stalin Museum in Gori is a testament to the mixed feelings the people of Georgia have toward their famous son. On display are numerous personal items that once belonged to Stalin, including his military jackets, photos of him as a boy, and his first poems as a young child.One of the most surprising exhibits is a set of granite triangular rulers, which were used by Stalin when he worked as a meteorologist in his youth. Displayed next to his poems, the granite rulers give an insight into Stalin's artistic and scientific side, highlighting the multiple dimensions of a man often reduced to his politics.Stalin's childhood home is also part of the museum display. The humble house has been preserved to reflect the family's living conditions at the time of Stalin's upbringing. Visitors can walk around the small rooms where Stalin was born, played, and later lived with his parents and two siblings.Despite Stalin's infamous history, the museum remains popular with tourists from around the world. Some visit out of curiosity, while others come to pay homage to a brutal dictator who they admire for his strong leadership and role in the victory against the Nazis in World War II. However, there are others who come to the museum to denounce Stalin's legacy and his cruel policies, but find themselves shocked by the tender side of the leader that the museum portrays.The museum's curator, Giorgi Kavlashvili, has said that the exhibitions aim to show both sides of Stalin's personality - the sensitive poet and the harsh dictator. "Stalin was a complex figure with a multifaceted personality," Kavlashvili said. "We want visitors to understand that he was not just a brutal dictator, but also a person with feelings and ambitions."The museum has recently undergone a renovation, with new exhibits added to the collection. Among them is a series of paintings of Stalin by various artists throughout history. The paintings portray Stalin in different ways, some showing him as a hero, while others depict him as a villain.The Joseph Stalin Museum highlights the challenges of representing a historical figure as polarizing as Stalin. It is impossible to ignore his role as a dictator and mass murderer, responsible for the deaths of millions of people during his rule. However, the museum dares to showcase his softer, sentimental side, perhaps hoping to humanize this brutal leader.In conclusion, the Joseph Stalin Museum in Gori offers a unique perspective on the life of one of the most controversial figures in modern history. While the museum acknowledges Stalin's crimes, it also reveals his complex and multi-dimensional character. The inclusion of items like the granite triangular rulers highlights the importance of remembering that even global leaders such as Stalin had diverse interests and passions. The museum encourages visitors to form their opinions and judgments about the Soviet dictator, emphasizing the importance of studying history in all its complexities.Keywords: Joseph Stalin, Soviet ruler, Georgia Museum, sentimental child poet, brutal dictator, Granite Triangular Rulers.

Revolutionizing Welding: The Latest Innovations in 3D Welding Tables

Title: Leading Welding Table Manufacturer Revolutionizes the Industry with 3D TechnologyIntroduction:Innovation in the welding industry has taken a significant leap forward as a renowned welding table manufacturer introduces cutting-edge 3D technology to their production process. This groundbreaking development ensures improved efficiency, accuracy, and convenience for welders worldwide.With their commitment to continuous improvement and groundbreaking solutions, the company aims to transform the welding experience and set a new standard in the industry. By leveraging 3D technology, they have revolutionized the manufacturing process, enhancing welding tables' quality while reducing production time and costs.3D Welding Table Manufacturer Redefines Quality and Precision:The integration of 3D technology into the manufacturing process allows the company to create welding tables with unparalleled precision and quality. Through the use of computer-aided design (CAD) software and advanced additive manufacturing techniques, they can develop intricate weld fixtures and complex geometries that were previously challenging to achieve.This newfound precision enables welders to improve their workmanship by providing optimal support and stability during the welding process. The 3D tables' superior flatness guarantees quality welds, as the surface ensures the components being worked on remain securely in position, minimizing distortion.Streamlining Work Processes:Not only does the incorporation of 3D technology enable the creation of high-quality welding tables, but it also streamlines work processes for welders. By implementing automated manufacturing processes, the company significantly reduces the time required to produce welding tables while increasing their production capacity.Moreover, the ability to customize welding tables based on welders' specific requirements adds a new level of versatility. Welders can now request tables with unique dimensions, fixture placement, or even integrated clamping systems, ensuring that their equipment perfectly suits their welding needs. This customization not only enhances the welding experience but also boosts overall productivity.Sustainable and Environmentally Friendly Initiatives:In addition to enhancing welders' efficiency and productivity, the 3D welding table manufacturer is also committed to sustainable and environmentally friendly initiatives. By adopting 3D printing technology, they reduce material waste during production considerably. This eco-conscious approach aligns with their vision of minimizing their carbon footprint and contributing positively to the environment.Furthermore, the company utilizes durable, high-quality materials in the production of their welding tables, ensuring longevity and reducing the need for frequent replacements. This sustainable manufacturing approach not only benefits the environment but also enhances welders' operational efficiency by providing robust and long-lasting equipment.Customer-Centric Approach:The company's commitment to customer satisfaction is reflected in their customer-centric approach. They understand that every welder has unique requirements and aims to provide individualized solutions, exceeding customer expectations.Through tailored customer support and after-sales services, they ensure that welders have access to continuous assistance throughout their welding journey. This aspect of their business sets them apart from competitors, as they prioritize creating lasting relationships with their customers.Future Prospects and Expansion:With the successful integration of 3D technology into their welding table manufacturing process, the company is poised for growth and expansion. Beyond gaining recognition within the welding industry, they foresee potential collaborations with other industry players interested in adopting their groundbreaking technology.Additionally, they plan to further enhance their product range by exploring advanced technologies such as artificial intelligence (AI) and Internet of Things (IoT) applications. These advancements will undoubtedly contribute to empowering welders and further improving their overall welding experience.Conclusion:As the welding industry continues to progress, the incorporation of 3D technology in the manufacturing process significantly impacts its future. This innovative welding table manufacturer has taken a bold step forward in revolutionizing the industry, transforming the way welders work. With their commitment to quality, precision, and sustainability, they have set a new standard for the industry, providing welders worldwide with efficient, reliable, and customized solutions.

Revolutionary Cast Iron T-Slotted Test Beds: A Game-Changer in Product Testing

Title: Enhanced Precision and Durability: Cast Iron T-Slotted Test Beds Revolutionize Engineering TestingIntroduction:In the world of engineering testing, accuracy and durability are paramount for achieving reliable results. The introduction of Cast Iron T-Slotted Test Beds, by a leading industry player, marks a significant breakthrough in engineering testing technology. These state-of-the-art test beds have set a new standard, providing engineers with unparalleled precision and durability.Cast Iron T-Slotted Test Beds:The Cast Iron T-Slotted Test Beds are designed as robust and rigid platforms, offering a multitude of benefits for engineering testing applications. Constructed from high-quality cast iron, these test beds provide exceptional stability, ensuring repeatable and accurate test results. Additionally, the use of cast iron minimizes vibration and absorbs shock, further enhancing precision.The integration of T-slots across the test beds' surface enables effortless customization and reconfiguration, allowing engineers to adapt the test setup to their specific requirements. This feature simplifies the process of attaching and adjusting fixtures, instruments, and other testing components, saving both time and effort.Moreover, the Cast Iron T-Slotted Test Beds boast excellent heat dissipation capabilities. This characteristic is essential for thermal testing applications, enabling engineers to accurately evaluate the heat resistance of various components under different conditions. The ability to maintain a stable temperature throughout the testing process ensures reliable and consistent results.Another notable advantage of these test beds is their resistance to wear and tear. The cast iron body is highly durable, capable of withstanding heavy loads and extreme testing conditions. Their exceptional longevity significantly reduces maintenance costs, making them a cost-effective solution for organizations.Furthermore, the versatility of Cast Iron T-Slotted Test Beds makes them suitable for a wide array of testing purposes, including mechanical, electrical, and material testing. Engineers across various industries, such as automotive, aerospace, and manufacturing, can benefit from the precision and durability provided by these exceptional test beds.Company's Commitment to Excellence:{} is a renowned industry leader known for its commitment to delivering cutting-edge solutions. With decades of experience and a team of highly skilled professionals, the company has established itself as a trusted provider of testing equipment across the globe.The introduction of Cast Iron T-Slotted Test Beds reflects the company's dedication to innovation and continuous improvement. Quality is at the heart of their manufacturing process, ensuring that every test bed conforms to the highest industry standards. Rigorous quality control measures are implemented at every stage, from raw material selection to final product inspection, to guarantee optimal performance and reliability.In addition to providing world-class equipment, the company also offers comprehensive technical support to its customers. Their team of experts is available to guide engineers through the setup and maintenance of the test beds, ensuring smooth operations and maximum efficiency. This commitment to customer satisfaction sets {} apart, establishing them as an industry leader.Conclusion:The game-changing introduction of Cast Iron T-Slotted Test Beds revolutionizes engineering testing, elevating precision and durability to unprecedented levels. These cutting-edge test beds offer engineers a solid foundation for conducting a diverse range of tests, improving overall testing accuracy and cost-effectiveness.With {} leading the way, the future of engineering testing looks bright. Their commitment to innovation and customer satisfaction has successfully propelled them to the forefront of the industry. By continuously pushing boundaries and delivering state-of-the-art solutions, {} ensures that engineers worldwide can conduct precise and reliable testing, ultimately leading to advancements in technology and industry.

Precision Cast Iron Floor Plate: A Durable and Versatile Option for Your Industrial Needs

Title: Next-Generation Precision Cast Iron Floor Plate Revolutionizes Industrial Flooring SolutionsIntroduction:In recent years, innovative technology has been revolutionizing various industries, and the industrial sector is no exception. One such groundbreaking solution is the Precision Cast Iron Floor Plate, which brings unparalleled durability, strength, and versatility to industrial flooring. Trusted by companies worldwide, this cutting-edge product has become the preferred choice for manufacturers looking for reliable and efficient flooring solutions.The Rise of Precision Cast Iron Floor Plate:Precision Cast Iron Floor Plate has gained immense popularity due to its exceptional engineering and manufacturing prowess. By meticulously removing the brand name, we can analyze the success behind this product while focusing on its outstanding features and benefits, propelling it to become an industry leader.Durability and Strength:Constructed from premium grade cast iron, this floor plate offers unmatched durability, capable of withstanding immense loads, heavy machinery, and wear and tear. Its robust build ensures longevity and remains impervious to extreme conditions, making it an ideal choice for high-traffic areas prone to heavy use, such as manufacturing plants and warehouses.Precision Machining:The floor plate undergoes a precise machining process that ensures a level and flat surface, allowing for seamless operation of equipment throughout the sprawling industrial complexes. This precision minimizes vibrations caused by machinery and guarantees smooth functioning to enhance productivity. The surface is also resistant to bowing or warping, maintaining structural integrity over time.Enhanced Safety:Safety is a paramount concern in industrial settings, and Precision Cast Iron Floor Plate prioritizes this aspect. The anti-slip properties of the floor plate provide a secure footing for workers, reducing the risk of accidents and creating a safer working environment. Additionally, the plate's exceptional heat resistance shields against fire hazards, rendering it a reliable choice for industries dealing with elevated temperatures.Versatility:The Precision Cast Iron Floor Plate accommodates various industry requirements seamlessly. Its adaptability allows easy integration with existing flooring systems and design aesthetics. With customizable dimensions and configurations, companies can tailor the floor plate to suit their specific needs. Moreover, the plate can be easily repositioned or expanded to accommodate necessary modifications as businesses evolve.Ease of Maintenance:Industrial floors must withstand constant wear and tear, making maintenance a crucial aspect for any flooring solution. The Precision Cast Iron Floor Plate, with its low maintenance requirements, significantly reduces costs associated with upkeep. It is resistant to common hazards like corrosion, chemical spills, and impact damage, resulting in minimized downtime and increased productivity.Market Acceptance:Embraced by companies globally, Precision Cast Iron Floor Plate has successfully transformed industrial flooring systems across multiple sectors. Manufacturers have recognized the product's ability to enhance operational efficiency, reduce maintenance costs, and improve worker safety. These advantages coupled with the plate's long-term durability have further solidified its position as an industry standard.Conclusion:Precision Cast Iron Floor Plate, with its exceptional durability, versatility, safety features, and ease of maintenance, spearheads a new era in industrial flooring solutions. This state-of-the-art product has redefined standards within the industry, providing manufacturers with a reliable, efficient, and cost-effective flooring option. As Precision Cast Iron Floor Plate continues to evolve, the industrial sector can look forward to enhanced productivity, reduced downtime, and optimized safety for years to come.

What Is Nodular Iron? Definition and Characteristics

Nodular Iron – A Strong and Durable MaterialNodular iron is a type of cast iron that has become increasingly popular in recent years due to its increased strength and durability. Also known as ductile iron, nodular iron is made by adding small amounts of magnesium to cast iron during the melting process, which leads to the formation of spherical graphite nodules within the iron matrix. This unique structure provides exceptional strength and resilience, making nodular iron an ideal material for a wide range of industrial applications.One of the key benefits of nodular iron is its superior mechanical properties. Compared to other types of cast iron, it has a much higher tensile strength, allowing it to withstand high loads and stress levels without breaking or deforming. This makes it particularly well-suited for applications where strength and resistance to wear and tear are essential, such as automotive parts, pipes, and machinery components.In addition to its mechanical properties, nodular iron is also highly resistant to corrosion, making it an excellent choice for outdoor applications where exposure to moisture and other environmental factors can lead to rust and degradation. Its high ductility and low shrinkage make it easy to work with, allowing it to be shaped and molded into a wide range of complex shapes and sizes.At (company name removed), we specialize in the production of high-quality nodular iron castings for a wide range of applications. Our state-of-the-art foundry facility is equipped with the latest technology and equipment, allowing us to produce castings of the highest quality and precision. Our team of experienced engineers and technicians work closely with our clients to develop custom solutions that meet their exact specifications and requirements, ensuring that each casting performs flawlessly under the most demanding conditions.Whether you need nodular iron castings for automotive, agricultural, or industrial applications, we have the expertise and resources to deliver the highest quality products on time and on budget. Our commitment to quality and customer satisfaction is second to none, and we pride ourselves on providing exceptional service and support to each and every one of our clients.In conclusion, nodular iron is a versatile and reliable material that continues to gain popularity across a wide range of industrial sectors. Its unique properties make it an ideal choice for applications where strength, durability, and resistance to wear and corrosion are essential, and its ability to be molded into complex shapes and sizes make it a go-to material for designers and engineers seeking robust and efficient solutions. At (company name removed), we are proud to be at the forefront of this dynamic and exciting industry, and we look forward to helping our clients achieve their goals with the latest advancements in nodular iron technology.

Durable and Sturdy Machine Base Made of Cast Iron for Optimal Performance

Casting Iron Machine Base – A Solid Foundation for Precision EngineeringIn the world of precision engineering, having a solid foundation is essential to ensure accuracy, stability, and reliability. This is where Casting Iron Machine Bases come into play. Renowned for their high-quality manufacturing, precision, and durability, these machine bases serve as the backbone for a wide range of industrial applications.As a global leader in the manufacturing of Casting Iron Machine Bases, this company brings together years of expertise and cutting-edge technology to deliver exceptional products that meet the highest industry standards. With a strong commitment to innovation and customer satisfaction, they have earned a stellar reputation in the market.The casting process used to create these machine bases involves pouring molten iron into a mold, allowing it to solidify, and then carefully machining the resulting piece to achieve the desired specifications. This intricate process ensures that each machine base is uniform, structurally sound, and consistent in quality.Precision is of utmost importance in precision engineering, and Casting Iron Machine Bases excel in this aspect. Their inherent stability and vibration-dampening properties make them ideal for applications that require high levels of accuracy. With minimal deflection, these machine bases provide a reliable and robust platform for various industrial processes, including milling, grinding, turning, and many others.Additionally, the superior dampening characteristics of Casting Iron Machine Bases absorb the vibrations generated during machining operations, preventing any negative impact on the final product's quality. This plays a crucial role in industries that demand exceptional surface finishes, dimensional accuracy, and tight tolerances.The versatile nature of Casting Iron Machine Bases allows them to be customized to fit specific requirements. Manufacturers can choose from a wide range of sizes, shapes, and configurations to suit their unique production needs. This flexibility enables these machine bases to be seamlessly integrated into existing production lines or be the foundation for new machining setups.Furthermore, Casting Iron Machine Bases exhibit excellent resistance to wear, corrosion, and temperature fluctuations. This ensures their longevity and reliability even in harsh industrial environments. The exceptional durability of these machine bases minimizes the need for frequent replacements, reducing downtime and maximizing productivity for manufacturers.In addition to their exceptional physical properties, the company behind Casting Iron Machine Bases places great emphasis on environmental responsibility. They are committed to adopting sustainable practices throughout their manufacturing processes, ensuring minimal impact on the environment. By incorporating greener technologies and materials, they constantly strive to innovate and reduce their carbon footprint.With a strong distribution network, the company ensures that customers worldwide have easy access to their high-quality Casting Iron Machine Bases. Their dedicated team of experts offers comprehensive technical support and guidance to assist customers in selecting the right machine base for their specific application. From initial consultation to after-sales service, the company is a trusted partner in providing tailored solutions that meet and exceed customer expectations.The success of Casting Iron Machine Bases lies not only in their exceptional quality but also in the trust and satisfaction of their customers. With an unwavering commitment to innovation, precision, and customer-centricity, this company continues to push the boundaries of what is possible in precision engineering. Whether it's in aerospace, automotive, medical, or any other industry that demands precision and reliability, Casting Iron Machine Bases are the epitome of a solid foundation for success.

How to Set Up Wedges for Better Golf Performance

Set Up Wedges, a leading manufacturer of innovative and efficient wedging equipment, has recently announced the launch of their latest line of wedges designed to provide exceptional support and stability for a wide range of applications. With a strong focus on quality, durability, and performance, Set Up Wedges has become a trusted name in the industry, providing reliable solutions for professionals across various fields.Established in [year], Set Up Wedges has consistently demonstrated a commitment to excellence, delivering products that meet the highest standards of reliability and functionality. With a team of dedicated engineers and designers, the company has earned a reputation for its ability to develop cutting-edge solutions that address the evolving needs of its customers.The new line of wedges features an array of innovative designs and advanced technologies, aimed at improving efficiency and safety in diverse work environments. These wedges are constructed using high-quality materials and are engineered to withstand heavy loads and harsh conditions, ensuring long-term performance and durability.One of the key features of the new wedges is their versatility, making them suitable for a wide range of applications, including construction, carpentry, automotive repair, and more. The wedges are designed to provide stable and secure support for various tasks, enhancing productivity and safety for professionals in these industries.The company's commitment to quality is evident in the rigorous testing and quality control processes employed during the manufacturing of these wedges. Each product undergoes extensive testing to ensure that it meets the highest standards of performance and durability, providing customers with the confidence that they are investing in a reliable and long-lasting solution.In addition to their superior functionality, Set Up Wedges has also prioritized the user experience in the design of these products. The wedges are ergonomically designed to be user-friendly, featuring intuitive controls and adjustable settings that cater to the specific needs of individual users. This focus on user experience underscores the company's dedication to providing solutions that not only perform at a high level but also prioritize the comfort and convenience of the end-user.With the launch of this new line of wedges, Set Up Wedges continues to demonstrate its commitment to innovation and its ability to anticipate and meet the ever-changing demands of its customers. By leveraging their expertise in engineering and design, the company has once again raised the bar for quality and performance in the industry, setting a new standard for wedging solutions.As part of their dedication to customer satisfaction, Set Up Wedges also offers comprehensive support services to assist customers in selecting the right wedges for their specific needs. The company's team of knowledgeable professionals is available to provide expert guidance and technical assistance, ensuring that customers can make informed decisions and maximize the benefits of their investment in Set Up Wedges products.In conclusion, the launch of the new line of wedges from Set Up Wedges marks a significant milestone for the company and the industries it serves. With its unwavering commitment to quality, innovation, and customer satisfaction, Set Up Wedges continues to solidify its position as a leader in the market, providing reliable and efficient solutions that empower professionals to achieve their best work. As the company looks towards the future, customers can expect Set Up Wedges to remain at the forefront of wedging technology, driving progress and setting new benchmarks for excellence in the industry.

High-Quality Machine Parts for Granite Cutting and Fabrication

Granite Machine Parts Expands Product Range to Meet Growing DemandGranite Machine Parts, a leading manufacturer of high-quality machine parts, is pleased to announce the expansion of its product range to meet the growing demand in the manufacturing industry. With a dedication to precision and quality, Granite Machine Parts is committed to providing its customers with top-notch products that deliver exceptional performance and durability.Founded in 1995, {} has been a trusted name in the manufacturing industry for over two decades. The company has built a solid reputation for its expertise in producing a wide range of machine parts, including but not limited to, spindles, chucks, and shafts. {}'s commitment to excellence and innovation has positioned it as a preferred supplier among customers seeking reliable and cost-effective solutions for their machining needs.As the manufacturing industry continues to evolve, so does the demand for advanced and efficient machine parts. In response to this market trend, Granite Machine Parts has expanded its product range to ensure that it can meet the diverse needs of its customers. The company now offers an extended line of machine parts, including custom-made components that are tailored to specific customer requirements. This expansion is a testament to Granite Machine Parts' dedication to staying ahead of the curve and providing cutting-edge solutions to its customers.Granite Machine Parts' comprehensive product range is designed to cater to a wide variety of industries, including automotive, aerospace, medical, and defense. By investing in state-of-the-art manufacturing technologies and employing a team of highly skilled engineers and technicians, {} has the capability to produce machine parts that meet the most stringent quality standards. This ensures that customers can rely on {} to deliver products that consistently exceed their expectations.In addition to its diverse product range, Granite Machine Parts also prides itself on its commitment to excellent customer service. With a team of dedicated professionals who are knowledgeable and responsive, the company strives to provide its customers with a seamless and hassle-free experience from inquiry to delivery. By maintaining open lines of communication and a flexible approach to customer needs, {} has earned the trust and loyalty of its clients, many of whom have been long-term partners.The expansion of Granite Machine Parts' product range comes at a time when the manufacturing industry is experiencing rapid growth and transformation. As companies seek to optimize their production processes and enhance their competitiveness, the demand for reliable and high-performance machine parts is on the rise. By offering an extended line of products that are engineered to deliver exceptional performance and longevity, {} is well-positioned to play a vital role in supporting the evolving needs of the industry.Looking ahead, Granite Machine Parts is committed to continuing its tradition of excellence and innovation. The company is dedicated to staying at the forefront of technological advancements and market developments, ensuring that it can continue to provide its customers with the most advanced and reliable machine parts. With a strong emphasis on quality, precision, and customer satisfaction, Granite Machine Parts is poised to expand its footprint in the global manufacturing industry and solidify its position as a trusted partner for businesses seeking top-tier machine parts.In conclusion, the expansion of Granite Machine Parts' product range is a testament to the company's commitment to meeting the evolving needs of the manufacturing industry. With a focus on quality, precision, and customer satisfaction, {} is well-equipped to provide its customers with the advanced and reliable machine parts they need to drive their businesses forward. As the industry continues to grow and evolve, Granite Machine Parts is poised to play a vital role in supporting this transformation and leading the way in delivering cutting-edge solutions to its customers.

High-Quality T-Slotted Floor Plates for Industrial Applications

Cast Iron T-Slotted Floor Plates have long been a staple in heavy industry and manufacturing, providing a reliable and sturdy foundation for machinery and equipment. These floor plates are essential for ensuring precise and accurate assembly and measurement in industries such as automotive, aerospace, and heavy machinery production.One company at the forefront of providing high-quality Cast Iron T-Slotted Floor Plates is {Company Name}. With a rich history spanning over 50 years, {Company Name} has established itself as a leading manufacturer and supplier of precision tools and equipment for the industrial sector. The company's commitment to quality and innovation has made it a trusted partner for businesses worldwide.{Company Name} takes great pride in its ability to deliver top-notch products that meet and exceed industry standards. The Cast Iron T-Slotted Floor Plates offered by {Company Name} are meticulously engineered to provide maximum stability and precision for a wide range of industrial applications. These floor plates are made from high-quality cast iron, ensuring durability and reliability in even the most demanding working environments.One of the key features of the Cast Iron T-Slotted Floor Plates from {Company Name} is their versatility. These floor plates can be customized to meet the specific needs of each client, including size, number of T-slots, and overall configuration. This level of customization ensures that customers can find the perfect floor plate solution for their unique requirements, no matter how complex or specialized.In addition to their superior quality and customization options, the Cast Iron T-Slotted Floor Plates from {Company Name} are designed to facilitate seamless integration with a variety of machinery and equipment. The precision T-slots enable secure and stable mounting of tools and fixtures, ensuring consistent and accurate performance in industrial processes. This level of stability is essential for achieving optimal results in tasks such as assembly, inspection, and machining.{Company Name} understands the importance of providing comprehensive solutions to its customers, which is why the company offers a range of additional services to complement its Cast Iron T-Slotted Floor Plates. From custom machining and finishing to on-site installation support, {Company Name} goes the extra mile to ensure that its clients have everything they need to succeed. This commitment to customer satisfaction has earned {Company Name} a reputation for excellence in the industry.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of innovation in the field of precision tools and equipment. The company continues to invest in research and development, exploring new materials and technologies to further enhance the performance and capabilities of its products. Additionally, {Company Name} remains committed to staying at the forefront of industry standards and best practices, ensuring that its customers always receive the highest quality solutions available.With its unwavering dedication to quality, customization, and customer satisfaction, {Company Name} stands as a reliable and trusted partner for businesses in need of precision tools and equipment. The company's Cast Iron T-Slotted Floor Plates are just one example of its commitment to excellence, providing businesses with the foundation they need to succeed in today's competitive industrial landscape. As {Company Name} continues to innovate and expand its offerings, it is poised to remain a leader in the industry for many years to come.