Durable Inspection Surface Plate for Cast Iron Materials

By:Admin

The Cast Iron Inspection Surface Plate is manufactured using high-quality casting techniques and is made from premium grade cast iron material. This ensures the highest level of stability, durability, and resistance to wear and tear, making it an ideal surface for precise measurement and inspection tasks.

One of the key features of the Cast Iron Inspection Surface Plate is its superior flatness and surface finish. With stringent quality control measures in place, each surface plate is meticulously inspected to ensure that it meets the highest industry standards. This level of precision and accuracy is crucial for industries where even the slightest deviation can have significant implications for the quality and reliability of their products.

In addition to its exceptional flatness, the Cast Iron Inspection Surface Plate also offers excellent resistance to thermal distortion and is capable of maintaining its dimensional stability under varying temperature conditions. This ensures that measurements taken on the surface plate are consistent and reliable, regardless of environmental factors.

Furthermore, [Your Company Name] understands the importance of versatility and customization in meeting the diverse needs of their customers. As such, the Cast Iron Inspection Surface Plate is available in a range of sizes and load capacities to accommodate different measurement requirements. Customers also have the option to request additional features such as T-slots, inserts, and material grades to further tailor the surface plate to their specific applications.

At [Your Company Name], customer satisfaction is paramount, and the introduction of the Cast Iron Inspection Surface Plate is a testament to their commitment to providing high-quality, reliable products to meet the evolving needs of the industry. With a team of experienced engineers and technical experts, the company is dedicated to supporting their customers in finding the most suitable solutions for their measurement and testing challenges.

In line with their dedication to customer support, [Your Company Name] also offers comprehensive after-sales services including installation, calibration, and maintenance to ensure that the Cast Iron Inspection Surface Plate continues to deliver optimal performance throughout its lifecycle. This level of support gives customers peace of mind knowing that they have a trusted partner to rely on for the long-term success of their operations.

The launch of the Cast Iron Inspection Surface Plate further solidifies [Your Company Name]’s position as a leading provider of precision measurement and testing equipment. With a strong emphasis on quality, reliability, and customer satisfaction, the company continues to set industry benchmarks and raise the bar for excellence in the field of metrology.

As industries strive for higher levels of precision and quality control, the demand for advanced measurement tools continues to grow. [Your Company Name]’s Cast Iron Inspection Surface Plate is poised to address these demands and make a significant impact on the way measurements are carried out across various sectors. With its outstanding flatness, durability, and customizable features, the surface plate is set to become an indispensable asset for companies seeking to elevate their measurement and inspection capabilities.

In conclusion, the introduction of the Cast Iron Inspection Surface Plate is a noteworthy milestone for [Your Company Name], underscoring their unwavering commitment to innovation and customer satisfaction. With its exceptional quality and performance, the surface plate is set to become a game-changer in the field of precision measurement and testing, further solidifying [Your Company Name]’s position as a trusted partner for businesses looking to achieve excellence in their operations.

Company News & Blog

Expert Guide to Choosing the Best Granite Measuring Tools for Precision Results

[Title]: Cutting-Edge Tools for Precision Measurement Revolutionize Granite Industry[Subtitle]: Introducing Innovative Tools Set to Redefine Granite Measuring Techniques[Opening paragraph]:In a groundbreaking announcement, GraniteTech—an industry leader in the production of high-quality tools—has unveiled their latest line of advanced measuring tools specifically designed for the granite industry. With a legacy of delivering excellence through innovation, this new set of tools promises to revolutionize the way granite is measured. By combining cutting-edge technology with the company's commitment to precision, GraniteTech is set to reshape the granite industry and provide professionals with the accuracy they need to achieve flawless results.[Company introduction]:GraniteTech, established in the early 2000s, has quickly evolved into a trusted name in the field of tools and equipment for granite processing. The company prides itself on its commitment to quality craftsmanship and has gained a reputation for developing reliable and durable tools. Over the years, GraniteTech has become synonymous with innovation, continuously pushing boundaries to deliver solutions that exceed customer expectations.[Paragraph 2]:Underpinning GraniteTech's new suite of tools is their latest invention—a state-of-the-art measuring device, the ProMeasure. With the ability to accurately measure even the most intricate details of granite slabs, these tools boast an unprecedented level of precision. The ProMeasure utilizes advanced laser technology coupled with intelligent software algorithms, which streamline the measurement process and eliminate any potential human error.[Paragraph 3]:One of the key features that sets the ProMeasure apart from traditional granite measuring tools is its ability to capture and store detailed measurements in a digital format. The device is equipped with an integrated storage system that allows professionals to readily access previously taken measurements, saving time and enhancing efficiency. The ProMeasure also offers the option of wireless connectivity to seamlessly transfer data to computers or smartphones, ensuring information is easily shareable amongst team members.[Paragraph 4]:Granite fabricators and designers will be pleased to know that the ProMeasure is not limited to traditional straight edge measurements. With the inclusion of innovative edge detection algorithms, this tool can accurately measure curved, irregular, and even three-dimensional surfaces. The ProMeasure's versatility expands the creative possibilities for granite artisans, empowering them to craft exquisite designs while maintaining dimensional accuracy.[Paragraph 5]:To ensure the ProMeasure seamlessly integrates into existing workflows, GraniteTech has developed a user-friendly interface. The intuitive touch screen display provides easy access to different measurement modes, enabling professionals to switch between functions effortlessly. Additionally, the device is lightweight and ergonomically designed, reducing user fatigue during prolonged use.[Paragraph 6]:GraniteTech's commitment to user-centric design extends beyond the ProMeasure itself. The company provides comprehensive training and support to ensure users maximize the full potential of these tools. GraniteTech's industry experts are available to guide professionals through various functions of the ProMeasure, ensuring seamless integration and optimal utilization.[Paragraph 7]:With its groundbreaking capabilities and usability, the ProMeasure has the potential to revolutionize the granite industry. Granite fabricators, architects, and designers will now be equipped with a tool that not only maximizes precision but also optimizes efficiency and productivity. By eliminating time-consuming manual measurements and minimizing human errors, the ProMeasure has the potential to drastically transform the way granite is processed and revolutionize the final results.[Closing paragraph]:GraniteTech's latest introduction of the ProMeasure proves their continued dedication to delivering innovative solutions that elevate industry standards. By fusing cutting-edge technology with their relentless pursuit of perfection, GraniteTech has shown commitment to propelling the granite industry forward. With the ProMeasure leading the charge, granite professionals can look forward to redefining the boundaries of precision and creativity, setting new benchmarks in the world of granite measurement.

Revive Your Blades with a Super Flat Granite Surface Plate

Granite Surface Plate Helps Restore Blades to PerfectionIf you're a woodworker or metal worker, you know how important it is to have a sharp blade. A dull blade not only makes it difficult to get a clean cut, but it can also be dangerous. That's why many professionals turn to a granite surface plate to restore their blades.The granite surface plate, also known as a surface table or precision granite plate, is a flat stone slab made of granite. This natural stone is prized for its hardness, durability, and resistance to wear and tear. Granite surface plates are often used in manufacturing, machining, and metrology to provide a flat surface for measuring and testing. But they are also becoming more popular among hobbyists and DIY enthusiasts for sharpening blades.One company that offers granite surface plates for blade restoration is Cool Tools. Based in Santa Fe, New Mexico, Cool Tools has been supplying craftsmen, metalworkers, and jewelry makers with high-quality tools and equipment since 1995. They offer a range of granite surface plates in different sizes and thicknesses, as well as other accessories to help with blade restoration.To use a granite surface plate for blade restoration, you'll need a piece of sandpaper or a sharpening stone and some honing oil. Simply lay the surface plate flat on a table or workbench, then place your blade on the plate at the desired angle. Start with a coarse grit sandpaper or stone to remove any nicks or chips in the blade, then move on to a finer grit to polish the edge. Apply honing oil to the surface plate to lubricate the blade and prevent it from overheating.One of the benefits of using a granite surface plate for blade restoration is its flatness. The surface plate is guaranteed to be flat within a certain tolerance, usually measured in microns. This means that the surface is perfectly level and straight, allowing you to sharpen your blade evenly and accurately. Some surface plates even come with calibration certificates that verify their precision.Another advantage of using a granite surface plate for blade restoration is its durability. Unlike other materials such as glass or metal, granite is less likely to warp or bend over time. This means that your surface plate will last for years, even with heavy use. Granite is also less likely to scratch or chip, which can damage your blade or cause it to become dull more quickly.In addition, granite surface plates are easy to clean and maintain. Simply wipe them down with a damp cloth after use to remove any debris or oil. You can also use a mild detergent if necessary. Avoid using harsh chemicals or abrasive cleaners, as these can scratch the surface and dull your blade.If you're interested in using a granite surface plate for blade restoration, consider purchasing one from Cool Tools. They offer a range of sizes and thicknesses to suit your needs, as well as other accessories such as honing oil and rubber feet to keep your surface plate stable during use. Cool Tools also offers excellent customer service and fast shipping, so you can start restoring your blades to perfection in no time.

Shop the Best Deals on Cast Iron Assembly Surface Plates

Cast Iron Assembly Surface Plate Pricelist: A Quality Solution for Your Manufacturing NeedsAs a leading manufacturer and supplier of industrial tools, we are proud to offer our Cast Iron Assembly Surface Plate, an indispensable tool for precise measurements and flatness inspections. Our high-quality cast iron surface plate is the ideal solution for manufacturing and quality control applications, ensuring accurate and reliable results in every use.Our Cast Iron Assembly Surface Plate is made from premium quality cast iron, which is known for its extreme hardness and resistance to wear and tear. This enables the plate to maintain flatness, resist warping and keep its shape over a long period of time, even with heavy usage. Additionally, our surface plate is properly seasoned, so it is resistant to corrosion and rust.In order to ensure that our Cast Iron Assembly Surface Plate meets the highest standards of quality, we use the latest technology and techniques in its production. Each plate undergoes meticulous inspection and testing before leaving our factory, ensuring that it meets the exacting standards required by our customers.Our Cast Iron Assembly Surface Plate is available in a range of sizes and specifications to meet the diverse needs of our customers. We also offer custom-made surface plates to meet specific requirements. For added convenience, each plate is accurately marked with a grid of lines and numbers, making it easy to take precise measurements.At an affordable price, our Cast Iron Assembly Surface Plate is a reliable tool for your manufacturing needs, providing long-lasting and accurate results. Our surface plate is the preferred choice of many major industries, including automotive, aerospace, machine shops, and metal fabrication.In order to see immediate results and improve your manufacturing processes, consider our Cast Iron Assembly Surface Plate today. Our high-quality and durable tool is sure to add value to your operations, and with competitive pricing, it is an investment that will pay dividends for years to come.About Our CompanyWe are a leading manufacturer and supplier of industrial tools and equipment, serving customers worldwide with high-quality, reliable, and cost-effective products. Our focus is on providing solutions that meet the unique needs of our customers, whether they are in the automotive, aerospace, construction, or medical device industries. We are committed to providing a superior customer experience, from the quality of our products to the efficiency of our service. Our expert team of engineers and technicians are experienced in developing customized solutions to meet even the most complex manufacturing requirements. As a dynamic and forward-thinking organization, we are constantly innovating and improving our products to provide the best possible value for our customers. With our state-of-the-art facilities and commitment to quality, we are well-positioned to continue providing advanced solutions for the modern manufacturing industry. ConclusionThe Cast Iron Assembly Surface Plate Pricelist is a testament to our commitment to providing high-quality and cost-effective solutions for the manufacturing industry. Our cast iron surface plates are a reliable and indispensable tool for any manufacturing and quality control application, providing accurate measurements, flatness inspections, and long-lasting durability. With competitive pricing and customized options, our surface plates are the ideal solution for your unique needs. Contact us today to learn more about our surface plates and other industrial tools.

Durable Cast Iron Test Plate for Strength and Performance Testing

Industrial NewsRenowned for their commitment to providing high-quality industrial products, {Company Name} has recently introduced a new line of cast iron test plates. This innovative product is designed to meet the growing demand for durable and reliable test plates in manufacturing and industrial sectors.The cast iron test plates are essential tools for ensuring the accuracy and precision of measuring instruments such as CMMs (coordinate measuring machines), height gauges, and surface plates. They are widely used for various applications including manufacturing, quality control, and calibration in industries such as aerospace, automotive, and heavy machinery.{Company Name} takes pride in its state-of-the-art manufacturing facilities and highly skilled workforce, which enable them to produce cast iron test plates that meet the industry's strict standards for flatness, surface finish, and overall accuracy. Each test plate undergoes rigorous quality control procedures to ensure consistent performance and reliability.The cast iron test plates offered by {Company Name} are available in a range of sizes and configurations to suit different applications. The company's product line includes standard plates, lapping plates, and custom-made plates to meet the specific requirements of their clients. The test plates are manufactured using premium-grade cast iron, known for its exceptional stability, thermal conductivity, and resistance to wear and corrosion.In addition to producing high-quality test plates, {Company Name} provides comprehensive support services to their customers. Their team of experienced engineers and technical specialists offers expert advice on selecting the right test plates for their clients' applications. The company also provides calibration services to ensure the accuracy of the test plates throughout their operational life.{Company Name} has built a strong reputation for delivering superior industrial products and services to a diverse customer base. With a focus on innovation and customer satisfaction, the company has established itself as a trusted partner for businesses seeking reliable solutions for their industrial needs.The introduction of the new line of cast iron test plates is a testament to {Company Name}'s commitment to meeting the evolving needs of the industry. The company's investment in research and development has enabled them to develop advanced manufacturing techniques and cutting-edge technology to produce test plates that meet the highest standards of quality and performance.The cast iron test plates offered by {Company Name} have already received positive feedback from customers who have praised their durability, accuracy, and long-term reliability. The company's dedication to excellence and continuous improvement ensures that their products remain at the forefront of the industry.As {Company Name} continues to expand its product offerings and services, the introduction of the cast iron test plates represents a significant milestone for the company. With their relentless pursuit of excellence, {Company Name} is poised to further solidify its position as a leading provider of industrial solutions for a wide range of applications.In conclusion, the introduction of the new cast iron test plates by {Company Name} underscores their commitment to innovation and customer satisfaction. With a focus on quality, reliability, and performance, the company continues to set the benchmark for industrial products in the global market.

High-Quality Steel Wedged Products for Multiple Applications

Steel Wedged Products, a leading manufacturer of cutting-edge industrial tools, is taking the industry by storm with its innovative and high-quality products. With a strong focus on technology and customer satisfaction, the company has established itself as a leader in the market and continues to set new standards in the industry.Steel Wedged Products is dedicated to providing top-of-the-line tools and equipment to its customers, catering to a wide range of industries including construction, automotive, mining, and agriculture. The company offers a diverse range of products including cutting tools, machining tools, and machine parts, all of which are designed to meet the highest standards of quality and performance.A key factor that sets Steel Wedged Products apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development to constantly improve its products and stay ahead of the curve. This commitment to innovation has allowed Steel Wedged Products to introduce cutting-edge technologies and solutions that have revolutionized the industry.One such example of Steel Wedged Products’ innovation is its advanced cutting tools, which are designed to deliver unmatched precision and efficiency. These tools are engineered with state-of-the-art materials and manufacturing techniques, ensuring superior performance and extended durability. Customers can rely on Steel Wedged Products’ cutting tools to deliver outstanding results, even in the most demanding applications.In addition to its innovative products, Steel Wedged Products is also renowned for its exceptional customer service. The company takes great pride in its ability to understand the unique needs of its customers and provide tailored solutions that exceed their expectations. Whether it’s providing expert technical advice or delivering custom-made tools, Steel Wedged Products goes above and beyond to ensure customer satisfaction.Furthermore, Steel Wedged Products is committed to upholding the highest standards of quality and safety. The company’s products undergo rigorous testing and inspection processes to guarantee their reliability and performance. With certifications and accreditations from industry authorities, customers can have full confidence in the quality and safety of Steel Wedged Products’ products.As a testament to its success and leadership in the industry, Steel Wedged Products has established a strong presence in both domestic and international markets. The company’s products are widely distributed and used by leading businesses and organizations around the world, further solidifying its reputation as a trusted and preferred supplier.Looking ahead, Steel Wedged Products is poised for continued growth and success. The company remains dedicated to pushing the boundaries of innovation and delivering unparalleled value to its customers. With a team of skilled professionals and a clear vision for the future, Steel Wedged Products is well positioned to maintain its position as a frontrunner in the industry.In conclusion, Steel Wedged Products stands out as a powerhouse in the industrial tools and equipment sector. With its unwavering commitment to innovation, quality, and customer satisfaction, the company continues to raise the bar and set new benchmarks for excellence. As it forges ahead, Steel Wedged Products will undoubtedly remain a force to be reckoned with in the industry.

Durable and Strong Machine Base Made of Casting Iron

Casting Iron Machine Base, a leading manufacturer of high-quality machine bases and components, has recently announced the launch of their latest product designed to meet the growing demands of the industry. The new machine base is set to revolutionize the manufacturing sector by providing exceptional stability, durability, and precision for various industrial applications.Established in [year], Casting Iron Machine Base has been at the forefront of the industry, delivering superior products and services to their clients worldwide. With a strong focus on innovation and excellence, the company has continuously raised the bar in terms of quality and performance, setting new standards within the manufacturing sector.The newly introduced machine base boasts a state-of-the-art design, meticulously engineered to offer unparalleled strength and rigidity. Constructed from high-quality cast iron, the base provides a stable foundation for a wide range of industrial machines, including lathes, milling machines, grinders, and more. The robust construction of the base ensures vibration dampening and enhanced cutting precision, resulting in higher productivity and superior finished products.Furthermore, the precision machining of the base guarantees tight tolerances and excellent flatness, contributing to consistent and accurate machining operations. This level of accuracy is crucial in today's manufacturing environment, where even minor deviations can lead to costly errors and production delays. By investing in the new machine base from Casting Iron Machine Base, manufacturers can expect to achieve higher levels of efficiency and product quality, ultimately gaining a competitive edge in the market.In addition to its superior engineering, the machine base is designed to withstand heavy loads and harsh working conditions, making it suitable for diverse industrial settings. Whether in a busy production facility or a rigorous machining environment, the durability of the machine base ensures long-term reliability and performance, minimizing downtime and maintenance costs for the end-users."We are thrilled to introduce our latest machine base to the market," said [Spokesperson's Name], the CEO of Casting Iron Machine Base. "At Casting Iron Machine Base, we are committed to empowering manufacturers with the tools they need to succeed. The new machine base exemplifies our dedication to quality and innovation, and we are confident that it will make a significant impact on our customers' operations."As a company with a strong emphasis on customer satisfaction, Casting Iron Machine Base offers customizable solutions to meet specific industry requirements. Clients can work closely with the company's team of experts to tailor the machine base according to their unique needs, ensuring seamless integration into their existing machinery and production processes.Moreover, Casting Iron Machine Base provides comprehensive technical support and after-sales services, demonstrating their ongoing commitment to client success. With a global presence and a reputation for excellence, the company is well-positioned to serve the needs of manufacturers across various sectors, including automotive, aerospace, metalworking, and beyond.The introduction of the new machine base further solidifies Casting Iron Machine Base's position as an industry leader, driving innovation and progress within the manufacturing sector. As technology continues to evolve and demand for precision machining rises, the company remains dedicated to pioneering solutions that empower manufacturers to thrive in a competitive market landscape.For more information about Casting Iron Machine Base and their range of products, visit their website at [website]. With a legacy of delivering quality and performance, the company stands as a trusted partner for manufacturers seeking cutting-edge solutions for their industrial needs.

High-Quality Cast Iron Assembly Surface Plate Suppliers

Cast Iron Assembly Surface Plate Suppliers are in high demand for various industries such as automotive, aerospace, and machinery manufacturing. These surface plates are essential for providing a flat and stable surface for the assembly and inspection of precision parts and components. When it comes to finding a reliable and trusted supplier for these critical tools, one company that stands out is {}.{} is a leading provider of cast iron assembly surface plates, offering a wide range of sizes and specifications to meet the diverse needs of their customers. With a strong focus on quality and precision, {} has earned a solid reputation as a preferred supplier in the industry.The company's dedication to excellence is evident in their commitment to using high-quality materials and advanced manufacturing processes. This ensures that their surface plates are not only durable and reliable but also meet the strict accuracy and flatness requirements demanded by their customers. Additionally, {} has a team of skilled engineers and technicians who have the expertise to design custom solutions for specific applications, further enhancing the value they bring to their clients.One of the key factors that set {} apart from other suppliers is their ability to provide a comprehensive range of services to support their customers throughout the entire lifecycle of the product. From initial consultation and design to manufacturing, testing, and after-sales support, {} is fully equipped to meet the needs of their clients every step of the way. This level of service and support has been a major contributing factor to the company's continued success and growth in the industry.In addition to their commitment to quality and customer satisfaction, {} also places a strong emphasis on innovation and continuous improvement. They invest in research and development to stay at the forefront of technological advancements, allowing them to offer cutting-edge solutions that meet the evolving needs of their customers.As the demand for cast iron assembly surface plates continues to grow, {} is well-positioned to meet the increasing needs of the market. With their extensive experience, technical expertise, and unwavering commitment to excellence, they are poised to remain a top choice for companies in need of reliable and high-quality surface plates for their manufacturing and assembly processes.Furthermore, {} recognizes the importance of environmental sustainability and is dedicated to minimizing their impact on the environment. They adhere to strict environmental standards and employ eco-friendly practices in their manufacturing processes, ensuring that their products are not only top-quality but also environmentally responsible.With a strong track record of success and a clear dedication to meeting the needs of their customers, {} continues to be a trusted partner for companies in need of cast iron assembly surface plates. Their combination of quality, expertise, and customer-centric approach positions them as a top supplier in the industry, and their commitment to innovation and sustainability ensures that they will remain a leader in the field for years to come.In conclusion, the demand for cast iron assembly surface plates continues to increase, and {} has proven themselves as a reliable and trusted supplier in the industry. With their dedication to quality, customer satisfaction, innovation, and sustainability, {} is well-equipped to meet the evolving needs of their customers and maintain their position as a top choice for companies in need of high-quality surface plates.

Quality Precision Granite Surface Plates for Industrial Use

Precision Granite Surface Plates are the foundation of successful and accurate metrology and engineering processes. These high-quality surface plates are essential tools for ensuring the precision and accuracy of measurement and inspection operations in various industries, including aerospace, automotive, machinery, and manufacturing. The solid and flat surface of the granite plates provides an ideal base for performing precise measurements and inspections, making them a crucial component in the quality control and manufacturing processes. With their exceptional stability, durability, and resistance to wear and corrosion, precision granite surface plates are widely recognized as the standard for reliable and accurate measurement tools.{Company Name}, a leading manufacturer of precision granite surface plates, has been at the forefront of providing top-quality metrology solutions to its customers for over 30 years. The company is committed to delivering high-precision products that meet the stringent demands of modern manufacturing and quality control processes. With state-of-the-art manufacturing facilities and a team of skilled technicians and engineers, {Company Name} has earned a reputation for excellence and reliability in the industry.One of the key factors that set {Company Name} apart from its competitors is the meticulous attention to detail and quality control in every stage of the manufacturing process. From the selection of premium-grade granite to the precision calibration and inspection of the finished surface plates, {Company Name} ensures that its products meet the highest standards of accuracy and reliability. This dedication to quality has made {Company Name} a trusted partner for businesses seeking superior metrology solutions.In addition to providing standard precision granite surface plates, {Company Name} also offers custom design and manufacturing services to meet the unique needs of its customers. Whether it's a specific size, shape, or surface finish requirement, the company's engineering team works closely with clients to create tailored solutions that align with their precise specifications. This flexibility and commitment to customer satisfaction have earned {Company Name} a loyal and satisfied customer base across various industries.{Company Name} also prioritizes innovation and continuous improvement in its product offerings. With a focus on leveraging the latest technologies and processes, the company consistently introduces new and advanced surface plate designs that align with the evolving needs of modern manufacturing and metrology practices. This commitment to innovation ensures that {Company Name} remains at the forefront of the industry, offering cutting-edge solutions that empower its customers to achieve exceptional levels of accuracy and reliability in their measurement and inspection processes.As part of its comprehensive metrology solutions, {Company Name} also provides a range of accessories and support equipment to complement its precision granite surface plates. These include stands, supports, and leveling devices that enhance the usability and functionality of the surface plates, enabling customers to optimize their measurement and inspection operations for maximum efficiency and accuracy.With a strong focus on customer service and satisfaction, {Company Name} takes pride in its ability to provide reliable and responsive support to its clients. The company's team of knowledgeable and experienced professionals is readily available to offer technical guidance, product recommendations, and after-sales support, ensuring that customers receive the assistance they need to leverage the full potential of their precision granite surface plates.In summary, precision granite surface plates from {Company Name} represent the pinnacle of reliability, accuracy, and quality in the field of metrology. With a steadfast commitment to excellence, innovation, and customer satisfaction, {Company Name} continues to be a trusted partner for businesses seeking top-quality metrology solutions that enhance their measurement and inspection processes. Whether it's standard surface plates or custom-designed solutions, customers can rely on {Company Name} to deliver products that meet the highest standards of precision and performance.

High-Quality 3D Welding Tables and Fixtures for Efficient Welding

When it comes to welding, precision and accuracy are essential for creating strong and durable welds. This is where 3D welding tables and fixtures come into play, providing a reliable and efficient solution for welders in various industries. These innovative tools are designed to streamline the welding process, ensuring that each weld is executed with utmost precision.One of the leading manufacturers of 3D welding tables and fixtures is {}, a company known for its high-quality welding products. With years of experience in the welding industry, {} has established itself as a trusted provider of welding solutions, catering to the needs of welders across the globe.The 3D welding tables and fixtures offered by {} are designed to meet the demands of modern welding processes. These tables are equipped with a range of features that make them ideal for a variety of welding applications. From adjustable clamping systems to precise leveling options, {}'s welding tables are engineered to enhance productivity and accuracy in the welding process. Additionally, their fixtures are designed to securely hold workpieces in place, allowing for consistent and controlled welds.One of the key benefits of using 3D welding tables and fixtures is their versatility. These tools can be easily customized to accommodate different welding requirements, making them suitable for a wide range of projects. Whether it's for manufacturing, automotive, or construction applications, {}'s welding tables and fixtures are designed to adapt to the specific needs of each welding job.Furthermore, {}'s commitment to quality is reflected in their use of premium materials and advanced manufacturing techniques. Each welding table and fixture is meticulously crafted to withstand the rigors of the welding environment, ensuring long-lasting durability and reliability. This dedication to quality has earned {} a reputation for delivering top-notch welding solutions that meet the highest industry standards.In addition to their technical excellence, {} also places a strong emphasis on customer satisfaction. The company's team of experts is dedicated to providing exceptional service and support to welding professionals, offering guidance and assistance to ensure that customers get the most out of their welding tables and fixtures. Whether it's through product training or technical assistance, {} is committed to helping welders optimize their welding processes.As the demand for efficient and reliable welding solutions continues to grow, {} remains at the forefront of innovation in the welding industry. With their cutting-edge 3D welding tables and fixtures, the company is poised to meet the evolving needs of welders and manufacturers, empowering them to achieve superior welding results with confidence and precision.In conclusion, 3D welding tables and fixtures have become essential tools for modern welding operations, and {} is a leading provider of these innovative solutions. With their unwavering commitment to quality, versatility, and customer satisfaction, {} continues to set the standard for excellence in the welding industry. As the company looks to the future, it is poised to further revolutionize the welding process, offering even more advanced and efficient solutions for welders around the world.

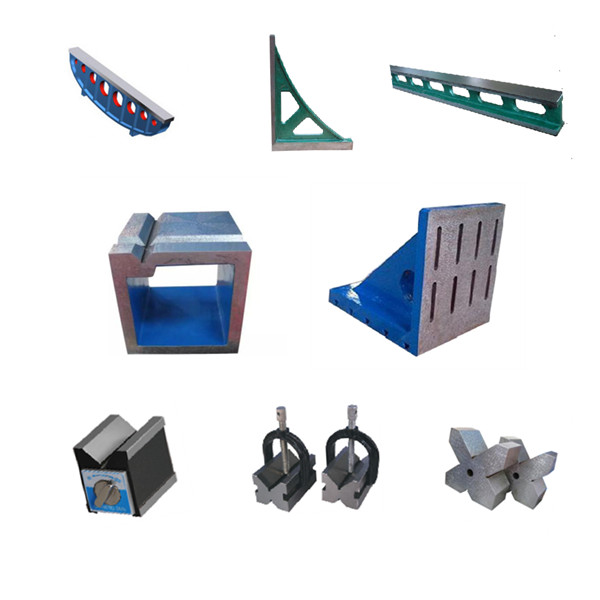

High-Quality Cast Iron Measuring Tools Manufacturers

Cast Iron Measuring Tools Manufacturers has been a leading name in the industry for over 50 years, providing high-quality measuring tools to industries such as construction, engineering, and manufacturing. The company has built a strong reputation for precision, durability, and reliability, making it a trusted choice for professionals around the world.With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, Cast Iron Measuring Tools Manufacturers has been able to consistently deliver top-notch products that meet the stringent demands of modern industry. The company's commitment to innovation and continuous improvement has allowed it to stay ahead of the curve and adapt to the changing needs of its customers.One of the key factors that set Cast Iron Measuring Tools Manufacturers apart from its competitors is its use of high-quality materials, such as cast iron, in the production of its measuring tools. This gives the tools exceptional strength and stability, making them ideal for use in tough working environments. Additionally, the company's stringent quality control measures ensure that every product that leaves the factory meets the highest standards of accuracy and performance.In a recent statement, the company's CEO expressed pride in Cast Iron Measuring Tools Manufacturers' long-standing reputation for excellence and dedication to customer satisfaction. "We have always been committed to providing our customers with the best possible products, and this has been the driving force behind our success," the CEO said. "Our focus on quality, innovation, and customer service has allowed us to build strong relationships with our clients and establish ourselves as a leader in the industry."Despite their already impressive range of products, Cast Iron Measuring Tools Manufacturers continues to invest in research and development to further enhance its offerings. The company is constantly exploring new technologies and manufacturing techniques to improve the performance, accuracy, and reliability of its measuring tools. This dedication to innovation ensures that Cast Iron Measuring Tools Manufacturers remains at the forefront of the industry and can continue to meet the evolving needs of its customers.The company's commitment to sustainability is another aspect that sets it apart from its competitors. Cast Iron Measuring Tools Manufacturers recognizes the importance of minimizing its environmental impact and has implemented various initiatives to reduce waste and energy consumption in its manufacturing processes. Additionally, the company is dedicated to ensuring the safety and well-being of its employees and has stringent health and safety protocols in place at its facilities.Looking ahead, Cast Iron Measuring Tools Manufacturers is poised for continued growth and success. With a strong track record of delivering exceptional products and a proven ability to adapt to changes in the industry, the company is well-positioned to capitalize on new opportunities and further solidify its position as a leader in the market.In conclusion, Cast Iron Measuring Tools Manufacturers has established itself as a trusted name in the industry, known for its commitment to quality, innovation, and customer satisfaction. With a rich history spanning over five decades, the company continues to push the boundaries of what is possible in the world of measuring tools and is dedicated to meeting the needs of its customers. As it looks to the future, Cast Iron Measuring Tools Manufacturers is poised to continue its success and remain a driving force in the industry for years to come.