Precision Surface Plate: The Complete Guide

By:Admin

The company is a leading manufacturer and supplier of high-quality industrial equipment and tools. With years of experience and a strong reputation in the industry, they have been dedicated to providing top-notch products to meet the needs of various manufacturing and engineering sectors. The company's commitment to precision, quality, and reliability has made them a trusted partner for countless businesses around the world.

[News Content]

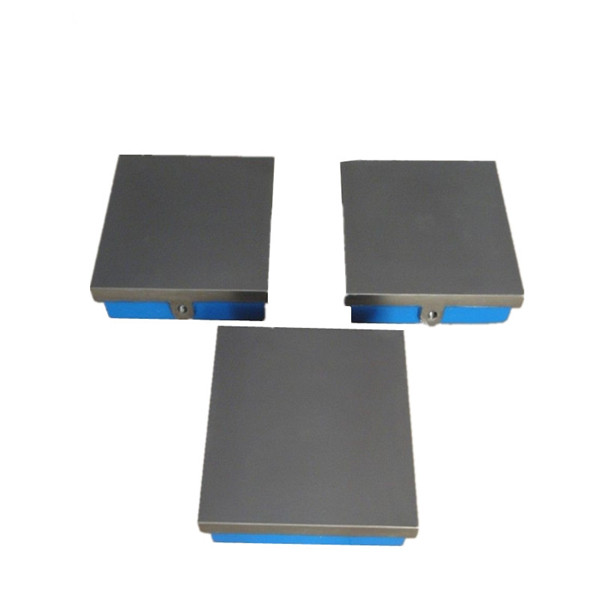

The Cast Iron Precision Surface Plate is a game-changer for industries that require precision and accuracy in their manufacturing processes. This heavy-duty surface plate is designed to provide a stable and reliable platform for performing various machining and inspection tasks with the highest degree of accuracy.

Manufactured using premium quality cast iron, this precision surface plate is meticulously hand-scraped to ensure a perfectly flat and smooth surface. The surface is then hand-finished to achieve the highest level of flatness and parallelism, making it an essential tool for ensuring the accuracy of machining operations and the quality of finished products.

The precision surface plate is available in a wide range of sizes and configurations to meet the diverse needs of different industries. Whether it's used for inspecting the flatness of a workpiece, setting up machining operations, or as a reference surface for measuring tools, this versatile tool offers unparalleled precision and reliability.

The company's dedication to quality and precision is evident in every aspect of the Cast Iron Precision Surface Plate. From the selection of the finest materials to the meticulous manufacturing and inspection processes, every step is taken to ensure that the end product meets the highest standards.

The precision surface plate is not only a superior tool for achieving precision in manufacturing processes, but it also offers exceptional durability and longevity. Its robust construction and high-quality materials make it a reliable investment for any workshop or manufacturing facility.

Furthermore, the company's renowned commitment to customer satisfaction is reflected in the exceptional service and support they provide. Customers can expect expert guidance in choosing the right precision surface plate for their specific needs, as well as ongoing technical support to ensure optimal performance and longevity.

In addition to the Cast Iron Precision Surface Plate, the company offers a comprehensive range of high-quality industrial equipment and tools to meet the diverse needs of their customers. From cutting tools and machining accessories to measurement instruments and workholding solutions, they are a one-stop-shop for all industrial manufacturing needs.

With a strong focus on innovation and continuous improvement, the company is constantly striving to bring new and improved products to market, ensuring that their customers have access to the latest advancements in industrial technology.

In conclusion, the Cast Iron Precision Surface Plate offered by the company is a testament to their unwavering commitment to quality, precision, and customer satisfaction. With its exceptional flatness, durability, and versatility, this precision tool is a valuable asset for any manufacturing or engineering operation that demands the highest level of accuracy and reliability. When it comes to precision machining and inspection, the company's precision surface plate is the go-to choice for professionals who demand nothing but the best.

Company News & Blog

What Is Nodular Iron? Definition and Characteristics

Nodular Iron – A Strong and Durable MaterialNodular iron is a type of cast iron that has become increasingly popular in recent years due to its increased strength and durability. Also known as ductile iron, nodular iron is made by adding small amounts of magnesium to cast iron during the melting process, which leads to the formation of spherical graphite nodules within the iron matrix. This unique structure provides exceptional strength and resilience, making nodular iron an ideal material for a wide range of industrial applications.One of the key benefits of nodular iron is its superior mechanical properties. Compared to other types of cast iron, it has a much higher tensile strength, allowing it to withstand high loads and stress levels without breaking or deforming. This makes it particularly well-suited for applications where strength and resistance to wear and tear are essential, such as automotive parts, pipes, and machinery components.In addition to its mechanical properties, nodular iron is also highly resistant to corrosion, making it an excellent choice for outdoor applications where exposure to moisture and other environmental factors can lead to rust and degradation. Its high ductility and low shrinkage make it easy to work with, allowing it to be shaped and molded into a wide range of complex shapes and sizes.At (company name removed), we specialize in the production of high-quality nodular iron castings for a wide range of applications. Our state-of-the-art foundry facility is equipped with the latest technology and equipment, allowing us to produce castings of the highest quality and precision. Our team of experienced engineers and technicians work closely with our clients to develop custom solutions that meet their exact specifications and requirements, ensuring that each casting performs flawlessly under the most demanding conditions.Whether you need nodular iron castings for automotive, agricultural, or industrial applications, we have the expertise and resources to deliver the highest quality products on time and on budget. Our commitment to quality and customer satisfaction is second to none, and we pride ourselves on providing exceptional service and support to each and every one of our clients.In conclusion, nodular iron is a versatile and reliable material that continues to gain popularity across a wide range of industrial sectors. Its unique properties make it an ideal choice for applications where strength, durability, and resistance to wear and corrosion are essential, and its ability to be molded into complex shapes and sizes make it a go-to material for designers and engineers seeking robust and efficient solutions. At (company name removed), we are proud to be at the forefront of this dynamic and exciting industry, and we look forward to helping our clients achieve their goals with the latest advancements in nodular iron technology.

Surface Plates: The Ultimate Precision Tool for Accurate Measurements A surface plate is a flat and solid plate used as a reference plane in the precision measurement process. It is commonly made from granite, cast iron, glass, or metal. Granite surface plates are highly preferred due to their superior performance. They are used for a range of applications such as inspection, marking, and quality control. Whether you are in the manufacturing, engineering, or scientific field, a surface plate is an essential tool for accurate measurements.

Surface plates are an essential tool for precision measurement in various industries such as manufacturing, engineering, and quality control. These large, flat plates provide a stable and accurate reference plane for measuring the flatness, straightness, and squareness of objects.Among the different materials used for surface plates, granite stands out as the best choice due to its excellent dimensional stability, high stiffness, and resistance to wear and corrosion. Granite surface plates are made from natural stone that is carefully selected, cut, and polished to achieve a high degree of flatness and surface finish.The quality of granite surface plates is crucial for the accuracy of measurements. A high-grade granite surface plate should have a flatness tolerance of less than ±0.0001 inch over its entire surface. This level of precision ensures that any object placed on the surface plate will be measured accurately, with minimal deviation from the true dimensions.One of the main uses of surface plates is inspection. Metrologists and quality control specialists use surface plates to check the dimensional accuracy of machined parts, gauges, and other tools. They also use surface plates to perform geometric measurements such as parallelism, perpendicularity, and concentricity.Another important application of surface plates is marking. Engineers and machinists use surface plates as a reference surface for laying out patterns, drilling holes, and machining features with high precision. The flatness and stability of the surface plate ensure that the marks or features will be placed in the correct location, with minimal deviation from the design specifications.In summary, a quality granite surface plate is an indispensable tool for accurate and reliable measurement in various industries. Its unique properties make it an ideal reference plane for inspection, marking, and other precision applications. If you want to ensure the highest level of accuracy in your measurements, invest in a high-quality granite surface plate today.

T-Slotted Floor Plates for Engineering Industry Applications

T-Slotted Floor Plates - An Essential Tool In The Engineering IndustryEngineering industries require durable and reliable equipment to facilitate efficient operations. The essential tools required include T-Slotted Floor Plates, which have a variety of uses within the industry. Some of the crucial benefits of using T-slotted floor plates are as follows:Rigid bases for layout marking and inspectionIn the engineering industry, accuracy is essential; thus, T-Slotted Floor Plates serve as a rigid base for layout, marking and inspection. The plates are made of cast iron, which provides the necessary strength and durability required for demanding applications. Additionally, the T-slots on the plates facilitate effortless anchoring of tools and inspection instruments, ensuring that they remain in the correct position. Ideal for assembly workT-slotted floor plates are also utilized in assembly work. They serve as an excellent base for large fixtures, special tooling, and production setups. The cast iron material can withstand heavy machinery and tools, making it suitable for precisions assembly work.Minimizes downtimeT-slotted floor plates provide a level surface, which minimizes the chances of machinery and component damages. In instances when machines and tools require maintenance or repair, the plates provide ample room for repairs without moving the machines. This minimizes downtime and increases productivity, which is crucial in the engineering industry.Customizable optionsT-slotted floor plates come in customizable sizes, including shape and design. The manufacturing industry provides clients with various options to meet their specific needs. A customized T-Slotted Floor Plate ensures specific components can be assembled at one time and boosts the accuracy of production set-ups.JASH Cast Iron T-Slotted Floor PlatesJASH Ltd is a leading manufacturer and supplier of cast iron T-slotted floor plates in India. JASH offers a wide range of floor plates, which is a preferred choice for various industries worldwide. The company ensures high quality in each product by using state-of-the-art technology in casting, machining, quality assurance, and customisation for its customers.JASH investment in modern technology enables them to manufacture and supply high-quality floor plates of various sizes, ranging from a width of 300mm to 6000mm and lengths of 1000mm up to a size of 12000mm. Each T-Slotted Floor Plate is subject to stringent testing to meet the high-quality requirements of the engineering and manufacturing industry. The quality-assurance process ensures that every plate meets the required specifications, providing clients with top-notch T-slotted floor plates.The cast iron material used by JASH ensures that the floor plates can withstand the heavy-duty requirements of the engineering and manufacturing industry. Additionally, customization ensures that clients' specific requirements are met, which improves overall productivity.In conclusion, JASH Ltd. offers a comprehensive range of products, including T-slotted floor plates, that can withstand all heavy-duty applications in the engineering industry. The customizable options provide clients with an array of choices, ensuring specific requirements are met. Clients can contact JASH for high-quality and durable T-slotted floor plates, which will improve the accuracy and productivity of their operations.

Top Cast Iron Test Bed Plate Suppliers in India - Verified Manufacturers and Suppliers for Cast Iron Plates and Griddles

India has always been a hub for manufacturing and supplying high-quality industrial equipment, and the Cast Iron Test Bed Plate is no exception. The Cast Iron Test Bed Plate is a crucial component used in various industries, including manufacturing, engineering, and construction. It serves as a stable and flat surface for testing, calibrating, and aligning various machines and equipment.In this blog post, we will take a look at the top Cast Iron Test Bed Plate suppliers in India and their products.1. M/s Bhawani Industries Private LimitedM/s Bhawani Industries Private Limited is one of the leading manufacturers and suppliers of Cast Iron Test Bed Plate in India. They offer a wide range of Cast Iron Test Bed Plates that are precision engineered and built to last. Their Cast Iron Test Bed Plates have a smooth surface finish and are available in various sizes and dimensions.2. P.A. Steel Co.P.A. Steel Co. is another prominent manufacturer and supplier of Cast Iron Test Bed Plates in India. They offer a wide variety of Cast Iron Test Bed Plates that are suitable for use in different industries. Their Cast Iron Test Bed Plates are known for their durability, stability, and superior quality.3. Dalal Engineering Pvt. Ltd.Dalal Engineering Pvt. Ltd. is a well-known manufacturer and exporter of Cast Iron Test Bed Plates in India. They have a team of skilled professionals who use advanced technology and machinery to create high-quality Cast Iron Test Bed Plates. Their Cast Iron Test Bed Plates are corrosion-resistant and have a long service life.4. Shiv Shakti Engineering WorksShiv Shakti Engineering Works is a reputable manufacturer and supplier of Cast Iron Test Bed Plates in India. They offer a wide range of Cast Iron Test Bed Plates that are made from high-grade cast iron and are available in various shapes and sizes. Their Cast Iron Test Bed Plates are known for their excellent finish, durability, and high strength.5. H C & CompanyH C & Company is a well-established manufacturer and supplier of Cast Iron Test Bed Plates in India. They provide various types of Cast Iron Test Bed Plates that are known for their high load-bearing capacity, smooth surface finish, and corrosion resistance. Their Cast Iron Test Bed Plates are suitable for various industrial applications and can withstand extreme temperatures and weather conditions.ConclusionThe Cast Iron Test Bed Plate is an essential component used in various industries, including manufacturing, engineering, and construction. There are several Cast Iron Test Bed Plate suppliers in India, and we have listed the top five in this blog post. When choosing a supplier for your Cast Iron Test Bed Plate needs, always look for a company that provides high-quality products, excellent customer service, and affordable prices.

Stylish Metallic Wedges for Spring Celebrations!

: The Perfect Choice for SpringSpring is the season of blossoming flowers, warmer temperatures, and most importantly, pre-wedding parties. As the wedding season kicks off, it's time to dust off those stylish wedges that have been hiding in the back of your closet. Wedges are perfect for spring as they are comfortable and provide the necessary support to strut with confidence.This year, there's a twist to the usual wedge style – metallic accents. Wedges with metal embellishments like studs, buckles, or straps add an edgy touch to the traditional design, making them perfect for any casual or formal occasion.Not sure where to start your search for the perfect metallic accent wedges? Fret not, for we have listed our five favorite metal-accented wedges that are sure to elevate your outfit and have you walking in style.1. Metallic Flatform Wedges: These wedges add an extra lift to your height without compromising on comfort. The metallic buckle and strap detailing add a subtle glam to your outfit.2. Embossed Metallic Wedges: If you're looking for something unique and eye-catching, these embossed metallic wedges are just what you need. The intricate detailing on the wedge heel and metallic straps make them a perfect choice for any evening event.3. Peep-Toe Metallic Wedges: A pair of peep-toe metallic wedges are perfect for a daytime event. The open-toe design and metallic detailing on the wedge add sophistication to any outfit.4. Metallic Studded Wedges: If you're looking for an edgier look, these studded wedges are perfect. The metallic studs on the wedge add a rocker-chick vibe to the traditional wedge design, making them perfect for a night out with friends.5. Strappy Metallic Wedges: Delicate and feminine, these strappy metallic wedges are perfect for a beach wedding or daytime event. The metallic straps add a pop of shine to the natural surroundings, making them a stylish choice for any outdoor event.In conclusion, metallic-accented wedges are a must-have for any fashion-forward individual looking to add a stylish twist to their spring/summer wardrobe. Whether you're attending a wedding or just heading out for the day, these wedges are sure to elevate your outfit and have heads turning. So, kick up your heels and strut your stuff with confidence in these stylish metallic-accented wedges.

Practical Guide to Scraping Cast Iron Surface Plates for Optimal Performance

In the world of manufacturing and engineering, precision is everything. When it comes to the accuracy of measuring and machining equipment, a high-quality surface plate is essential. However, over time, even the best surface plates will become worn and damaged, reducing their accuracy. That is where Scraping Cast Iron Surface Plate comes into play. Their specialized grinding and scraping techniques are used to restore even the most heavily damaged surface plates back to their original precision.Scraping Cast Iron Surface Plate, founded in 1993, is a professional manufacturing company that specializes in the production and maintenance of surface plates. They have been providing high-quality products and services to various industries, including the automotive, aerospace, and machine tool industries, for over two decades.Their team of highly skilled technicians uses advanced grinding and scraping techniques to repair and refurbish surface plates of all sizes. The processes they use are carefully designed to restore the original precision of the surface plate, making it as good as new. Additionally, they use only the highest-quality materials in their repairs, ensuring that the surface plate will continue to perform beautifully for many years to come.To ensure that their clients' needs are met, Scraping Cast Iron Surface Plate offers a wide range of services. They provide essential repairs, as well as complete refurbishments, to all types of surface plates. Their team can even design and produce custom surface plates tailored to specific needs. They can also perform on-site inspections, providing clients with a detailed analysis of the performance of their equipment.In recent years, Scraping Cast Iron Surface Plate has been recognized in the industry for their exceptional quality and service. Their commitment to excellence has earned them a loyal following of clients who rely on their expertise and precision in restoring surface plates.One of the company's recent projects involved restoring a surface plate used in a high-precision aerospace application. The plate had developed significant damage due to heavy use, and the client was concerned that a replacement would be needed. Scraping Cast Iron Surface Plate was called in to assess the damage and provide a solution. After carefully inspecting the plate, they determined that it could be repaired and set to work grinding and scraping the damaged areas. After a meticulous restoration process, the surface plate met the original accuracy specifications and was put back into service.Scraping Cast Iron Surface Plate's dedication to excellence and precision has earned them a reputation as one of the best surface plate repair and refurbishment companies in the industry. Their commitment to quality and unparalleled customer service makes them a trusted partner for companies looking to maintain the accuracy and efficiency of their equipment.In conclusion, when it comes to ensuring the precision and accuracy of surface plates, Scraping Cast Iron Surface Plate is the company to call. Their combination of state-of-the-art grinding and scraping techniques, as well as their commitment to using only the highest quality materials and providing exceptional customer service, makes them an industry leader in surface plate repair and refurbishment. Whether clients need a simple repair or a complete refurbishment, Scraping Cast Iron Surface Plate is the trusted partner that can get the job done right.

Top 3D Worktable Made of Cast Iron Revealed in Latest News

Industrial advancements have made it possible for businesses to increase the efficiency of their operations and attain higher levels of productivity. For manufacturers, having the right tools and equipment in the production process can make a significant difference in their output. With this in mind, one company has introduced a game-changing product that promises to revolutionize the manufacturing industry.The cast iron 3D worktable, from a reputable company specialized in machine tool accessories and metalworking, is a new essential tool in manufacturing. Designed to withstand heavy loads and provide excellent precision, the table is an ideal platform for a range of operations, including milling, drilling, and grinding. With this new product, industrial operations will be able to achieve better levels of accuracy, reliability, and stability in their processes.The cast iron 3D worktable has been engineered with cast iron material that is famous for its durability and stability, making it suitable for heavy-duty applications. With perfectly milled surfaces, the table ensures that workpieces remain in place and can withstand vibrations and pressure, while at the same time providing the user with a level of precision that is unmatched by other conventional worktables.The table's flat and smooth surface allows for smooth travel of workpieces while maintaining accuracy and precision. Additionally, the table comes with T-slots that offer a perfect fit for clamping and securing workpieces in place, increasing the table's versatility while minimizing safety risks in the workplace. This feature makes the table ideal for a variety of industrial uses, including but not limited to metalworking, manufacturing of machinery and equipment, and construction.The manufacturer has employed modern technology to develop the cast iron 3D worktable, incorporating Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) in the design and manufacturing processes. The result is a product that provides unrivaled accuracy and dependability, making it ideal for use in precision applications.The company behind the cast iron 3D worktable is a well-respected leader in the machine tool accessories and metalworking industry. With a history of providing top-notch technology to various industries worldwide, the manufacturer has established a reputation for quality, reliability, and exceptional customer service. The addition of this product to their line-up follows their tradition of offering superior equipment and accessories that meet the changing needs of their customers.According to the product manager, "The cast iron 3D worktable is designed to deliver unmatched performance and stability while providing our customers with the flexibility they need in their operations. Our engineers have taken into consideration the demands of industrial workspaces, and we are confident that the table will make a significant contribution to modernizing the manufacturing industry."The cast iron 3D worktable comes in various sizes, providing versatility for multiple operations. This new product is an investment that will pay for itself, as its durability and longevity ensure it will last for generations to come. This essential tool will bring reliability, stability, and precision to various industrial operations and can be the difference between a successful or unsuccessful project.In conclusion, with the introduction of the cast iron 3D worktable, the manufacturing industry will experience enhanced stability, accuracy, and productivity. The utilization of cast iron material, coupled with modern technology, has resulted in a product that delivers optimal performance. This new addition to the company's range of machine tool accessories is evident of their commitment to excellence and meeting the changing needs of their customers. With this new product, the manufacturing industry is one step closer to modernization.

Efficient Cast Iron Surface Inspection Plate: Exploring Top Features and Benefits

Cast Iron Surface Inspection Plate Finds New Applications in Industry[Company Logo][Company Name], an industry leader in manufacturing and marketing industrial equipment, is proud to announce the release of their latest product, the Cast Iron Surface Inspection Plate. This innovative piece of equipment is designed to revolutionize the inspection process in various industries, improving both efficiency and accuracy.The Cast Iron Surface Inspection Plate is a robust, versatile, and reliable tool that ensures precise and thorough inspection of complex components. It is made from high-quality cast iron, known for its durability, stability, and resistance to wear and tear. The plate's flat and polished surface provides a stable and true reference point for inspection purposes, reducing the risk of errors in measurement.One of the key features of this inspection plate is its compatibility with modern digital technologies. The plate includes strategically placed mounting positions for cameras, sensors, and measurement devices, allowing for the seamless integration of digital inspection systems. This enables real-time monitoring and instant analysis of the inspected parts, leading to faster decision-making and improved overall quality control.The Cast Iron Surface Inspection Plate is not limited to a specific industry or application. Its versatile design makes it suitable for use in various sectors, including automotive, aerospace, energy, and manufacturing. Whether inspecting engine components, turbine blades, precision-machined parts, or any other critical equipment, this tool ensures accurate measurements and inspections, ultimately improving the reliability and safety of the products.Furthermore, the Cast Iron Surface Inspection Plate offers significant benefits in terms of cost reduction and time-saving. Traditional inspection methods often involve multiple setups and elaborate procedures, leading to increased downtime and higher labor costs. However, with the use of this inspection plate, the process becomes streamlined and simplified. It eliminates the need for extensive calibration and repetitive setups, reducing inspection time and increasing productivity.The new inspection plate is also designed with ergonomics in mind. It features an anti-slip coating, ensuring a secure working environment for operators. The lightweight construction allows for easy transportation and maneuverability, contributing to the overall efficiency of the inspection process. Additionally, the plate is resistant to environmental factors such as corrosion or temperature variations, making it suitable for use in different working conditions.[Company Name] has always been at the forefront of innovation in the industrial equipment sector. Their commitment to research and development has resulted in groundbreaking products that meet the evolving needs of various industries. The introduction of the Cast Iron Surface Inspection Plate reinforces their dedication to providing cutting-edge solutions that improve quality control and inspection processes.The company's CEO, [CEO Name], expressed enthusiasm about the new product, stating, "We believe that the Cast Iron Surface Inspection Plate will revolutionize the inspection process in industries worldwide. Its versatility, compatibility with digital technology, and ergonomic design make it a valuable tool for improving efficiency and ensuring accurate measurements. We are confident that this product will meet and exceed our customers' expectations."In conclusion, the introduction of the Cast Iron Surface Inspection Plate marks a significant milestone in the field of industrial equipment. With its robust construction, compatibility with digital technologies, and adaptability to various industries, this inspection plate is set to transform the inspection process, improving efficiency, accuracy, and cost-effectiveness. [Company Name]'s commitment to innovation and customer satisfaction shines through their latest offering, reinforcing their position as a leading provider of industrial equipment.

Discover the Properties and Uses of Cast Iron: A Comprehensive Guide

Cast iron is a material that is popularly used in many different industries due to its strength, durability, and versatility. One type of cast iron that has gained traction in recent years is spheroidal cast iron, also known as ductile iron. This material offers a number of advantages over traditional cast iron, including greater resistance to deformation and cracking.One of the key benefits of spheroidal cast iron is its unique microstructure, which allows for greater strength and toughness. Unlike traditional cast iron, which is brittle and prone to cracking under stress, spheroidal cast iron is able to deform and absorb shocks without breaking. This makes it ideal for use in applications where high levels of stress are expected, such as automotive components and machinery parts.In addition to its superior strength and toughness, spheroidal cast iron also offers excellent machinability and weldability. This makes it easier to fabricate and work with than other types of cast iron, and allows for greater customization and fine-tuning of parts and components.Another advantage of spheroidal cast iron is its resistance to corrosion and wear. This makes it ideal for use in harsh environments where exposure to abrasive materials or chemicals can cause other materials to break down over time.Overall, spheroidal cast iron is an excellent choice for a wide range of industrial applications. Its unique combination of strength, toughness, and durability make it an attractive option for manufacturers looking to create high-quality and reliable products. So whether you're building a new machine part or designing a complex automotive component, spheroidal cast iron is definitely worth considering.

High-Quality Machine Components for Granite Materials

Granite Machine Components, a leading manufacturer of high-quality machine components, is proud to announce the launch of their latest line of products designed to meet the needs of modern manufacturing industries. The company, which has been in operation for over two decades, is known for its commitment to excellence and innovation in the field of machine component manufacturing. With the introduction of their new line of products, Granite Machine Components continues to demonstrate their dedication to providing cutting-edge solutions to their customers.The new line of products from Granite Machine Components includes a wide range of machine components, including precision-ground granite surface plates, granite squares, granite parallels, and granite straight edges. These components are designed to provide accurate and reliable measurements for a variety of industrial applications, making them an essential tool for today's manufacturing industry. With their superior quality and durability, these components are built to withstand the rigorous demands of modern manufacturing environments.Granite Machine Components has earned a strong reputation for delivering high-quality products that meet the industry's stringent standards. Their team of highly skilled engineers and technicians work tirelessly to ensure that each product meets the company's exacting standards for precision and performance. By leveraging advanced technology and innovative manufacturing processes, Granite Machine Components has continually raised the bar for excellence in the industry."We are thrilled to introduce our new line of products, which represent the latest advancements in machine component manufacturing," said the CEO of Granite Machine Components. "Our goal is to provide our customers with the most reliable and accurate components that will help them optimize their manufacturing processes and achieve greater efficiency. With our new line of products, we are confident that we can meet and exceed the needs of our customers, and we look forward to continuing to lead the industry in delivering top-quality machine components."In addition to their commitment to producing high-quality products, Granite Machine Components also places a strong emphasis on customer satisfaction. The company prides itself on its responsive and knowledgeable customer service team, which is dedicated to providing support and assistance to customers throughout the entire purchasing process. Whether it's helping customers select the right components for their specific needs or providing technical support after purchase, Granite Machine Components is committed to ensuring that every customer is completely satisfied with their experience.As a company with a strong focus on innovation and continuous improvement, Granite Machine Components is constantly exploring new ways to enhance their products and processes. Their research and development team is dedicated to staying at the forefront of advancements in the industry, enabling the company to anticipate and meet the evolving needs of their customers. With a strong emphasis on staying ahead of the curve, Granite Machine Components is well-positioned to continue leading the industry in providing state-of-the-art machine components.With the launch of their new line of products, Granite Machine Components is poised to further solidify its position as a premier provider of machine components to the manufacturing industry. By delivering products that offer unmatched precision, durability, and reliability, the company is helping its customers achieve greater success in their respective industries. As they continue to push the boundaries of what is possible in machine component manufacturing, Granite Machine Components remains dedicated to providing the highest level of quality and service to its customers.